Lifter without cracking bucket

A bucket elevator, non-crushing technology, which is applied in agricultural machinery and tools, threshing equipment, elevators in buildings, etc., can solve the problem that the broken bucket elevator cannot be eradicated, and the problem of rolling materials cannot be completely solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

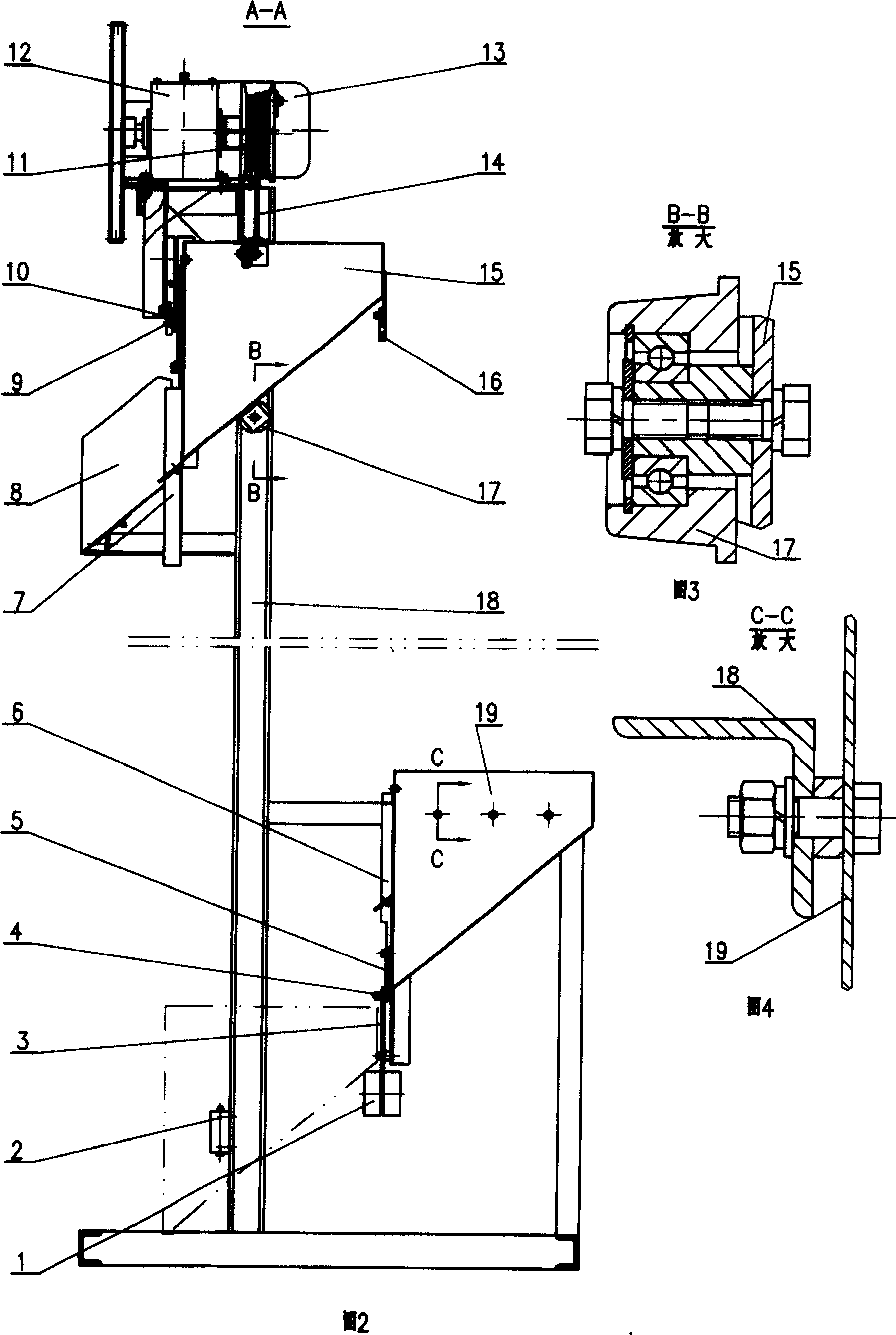

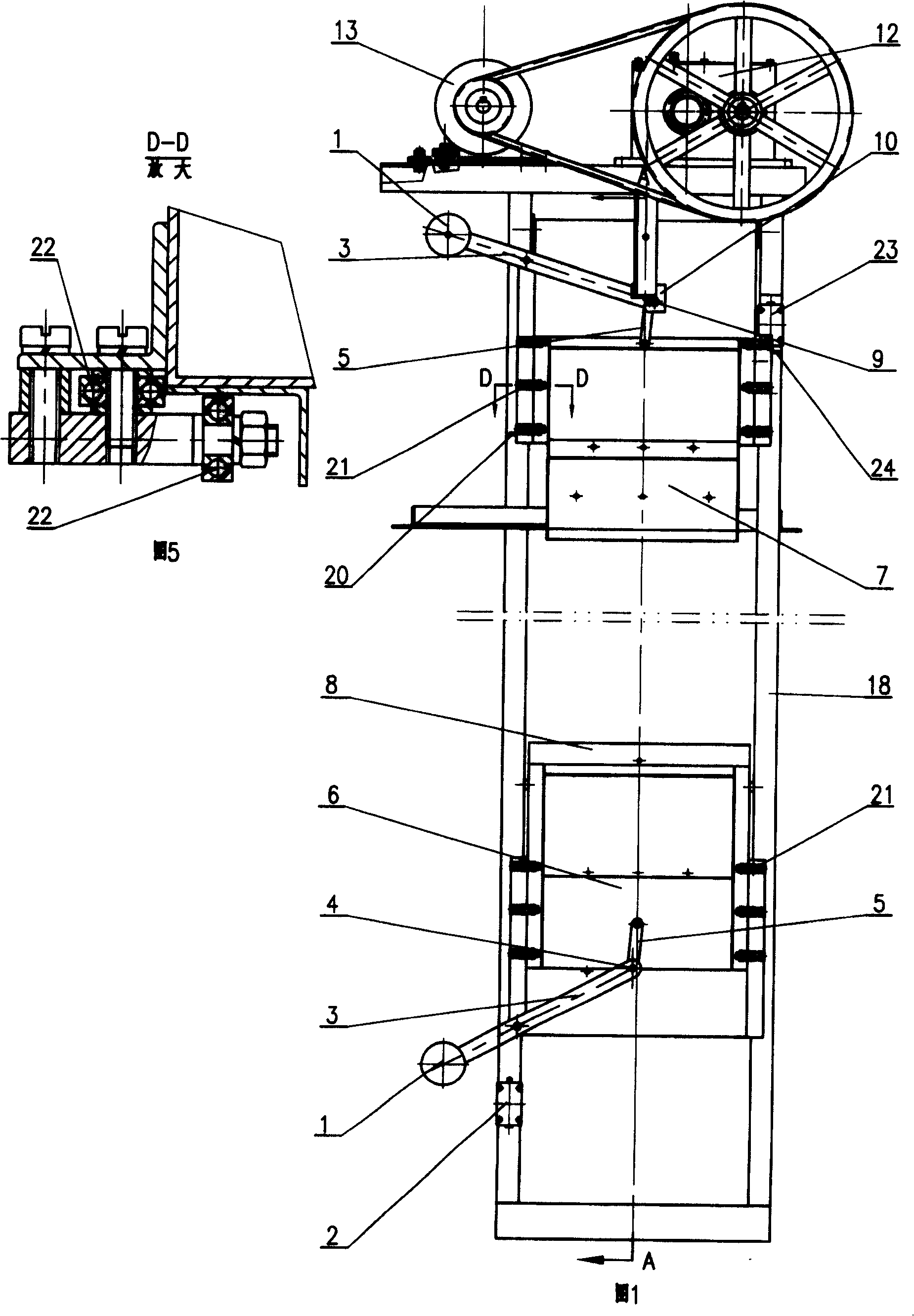

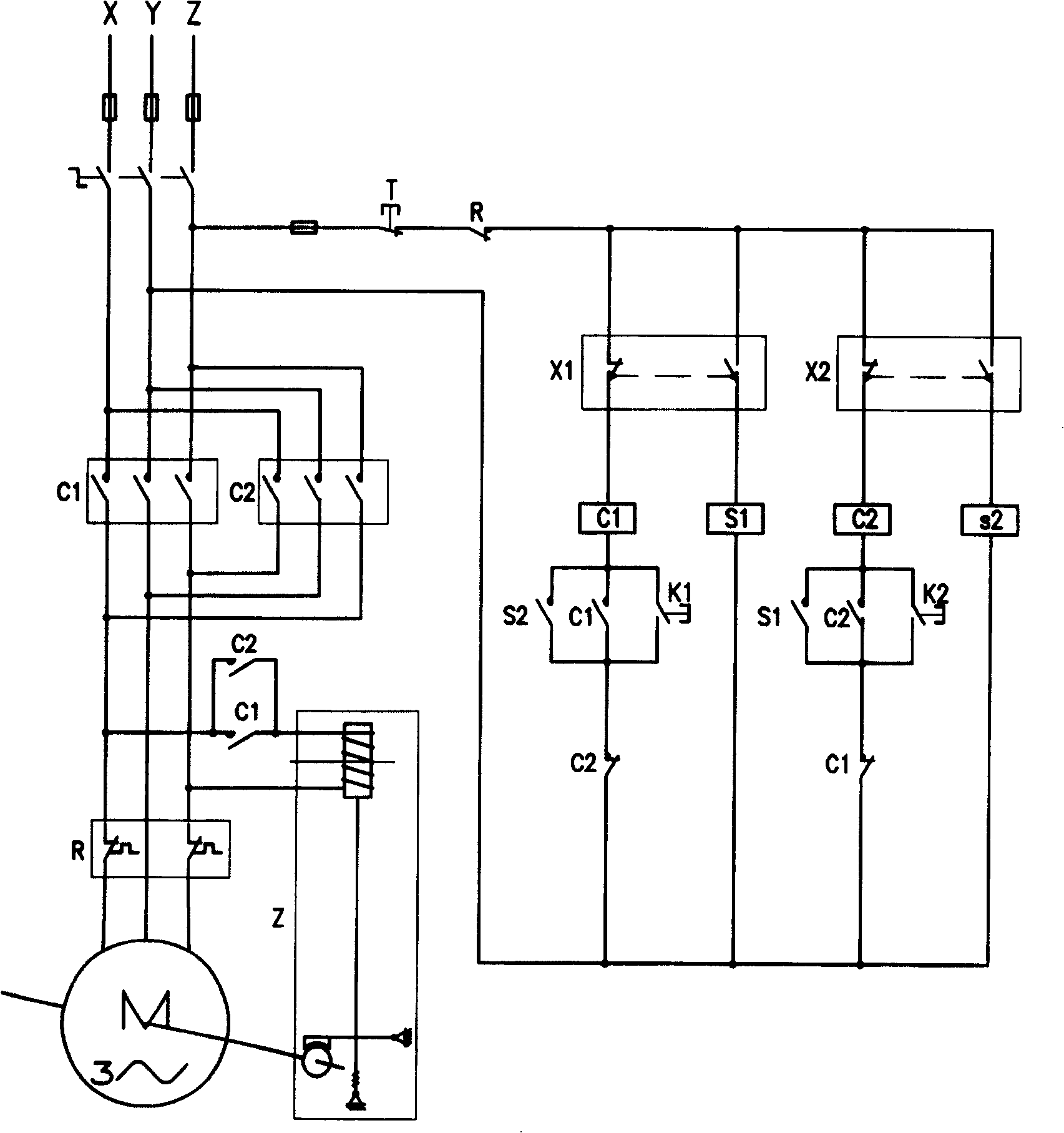

[0009] With reference to accompanying drawing, motor 13 and gearbox 12 that have power-off brake all are contained on the platform that section steel is welded into above frame 18. The motor 13 passes the power to the gearbox 12. After the speed change, the rope pulley 11 on the gearbox 12 obtains the speed needed to drive the lifting bucket 15 to move up and down, which can be selected as required. One end of the wire rope 14 that is wound on the sheave is fixed on the lifting bucket 15 upper ends. The rollers 17 arranged up and down on both sides of the elevator bucket 15 are contained in the corresponding grooves of the two upright channel steels of the frame 18, so that the elevator bucket 15 moves linearly up and down. Roller 17 is installed on the hollow shaft by bearing, is fixed on lifting bucket 15 sides with bolt. 4 The plane formed by the axes of the rollers 17 makes the volumes of the hoppers on both sides equal, and the center of the wire rope 14 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com