Reciprocating superconducting magnetic separator

A technology of superconducting magnetism and sorting machines, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., and can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings, so as to help understand the content of the present invention.

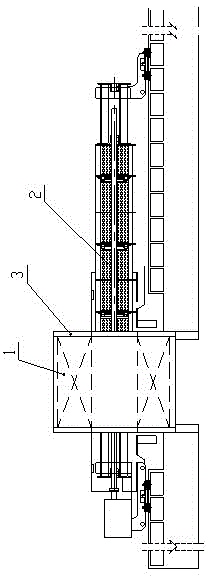

[0013] Such as Figure 1 to Figure 2 Shown, the present invention comprises a kind of reciprocating superconducting magnetic separator, comprises solenoid type superconducting magnet 1 and sorting mechanism, and described sorting mechanism is located at the center of horizontal solenoid type superconducting magnet 1 In the hole, the sorting mechanism includes a main body 2 that can move horizontally in the magnetic field, and the main body 2 includes an adsorption body with an adsorption cavity inside and a "dummy" body required by the sorting process; the solenoid type A ferromagnetic shielding layer 3 is arranged around the superconducting magnet 1 .

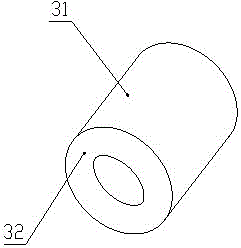

[0014] The ferromagnetic shielding layer 3 includes a cylinder 31 and two end walls 32. The end wall 32 is an annular shape with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com