Automatic detection and classification device for leakage procedure of bearing ring

A bearing ring, automatic detection technology, applied in sorting and other directions, can solve problems such as affecting production efficiency, not eliminating errors, and affecting production equipment, so as to improve production efficiency and product qualification rate, avoid classification errors, and reduce human labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

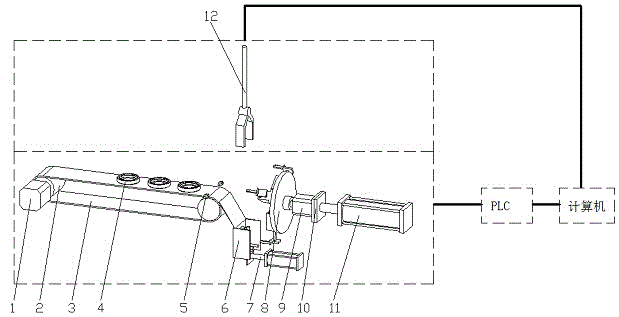

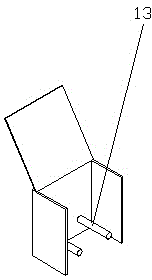

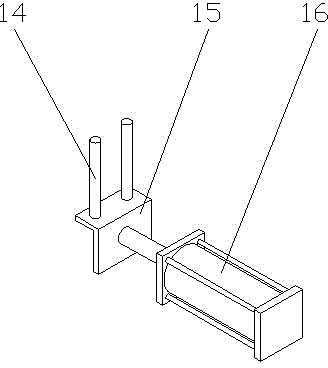

[0022] Such as Figure 1~Figure 6 As shown, an automatic detection and classification device for bearing ring leakage process is controlled by PLC and computer, and includes a material transmission mechanism, a material clamping mechanism 7, a mold changing turntable 8, and a manipulator 12; the material transmission mechanism includes a stepping motor I1, pulley 2, conveyor belt 3, through-beam photoelectric switch 5, material chamber 6 and a pair of positioning rods 13, the material clamping mechanism 7 includes a pair of clamping rods 14, connecting plate I15 and cylinder I16, the The mold changing turntable 8 includes a detection mold I18, a detection mold II21, a detection mold III22, a connecting plate II19, three cylinders II20, a proximity switch 17, a turntable 23, a stepping motor II9, a mounting plate 10, and an air cylinder III11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com