Building steel tube correcting device

A steel pipe and construction technology, applied in the field of construction steel pipe correction device, can solve the problems of high labor intensity, low efficiency, physical energy consumption, etc., and achieve the effect of good correction effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

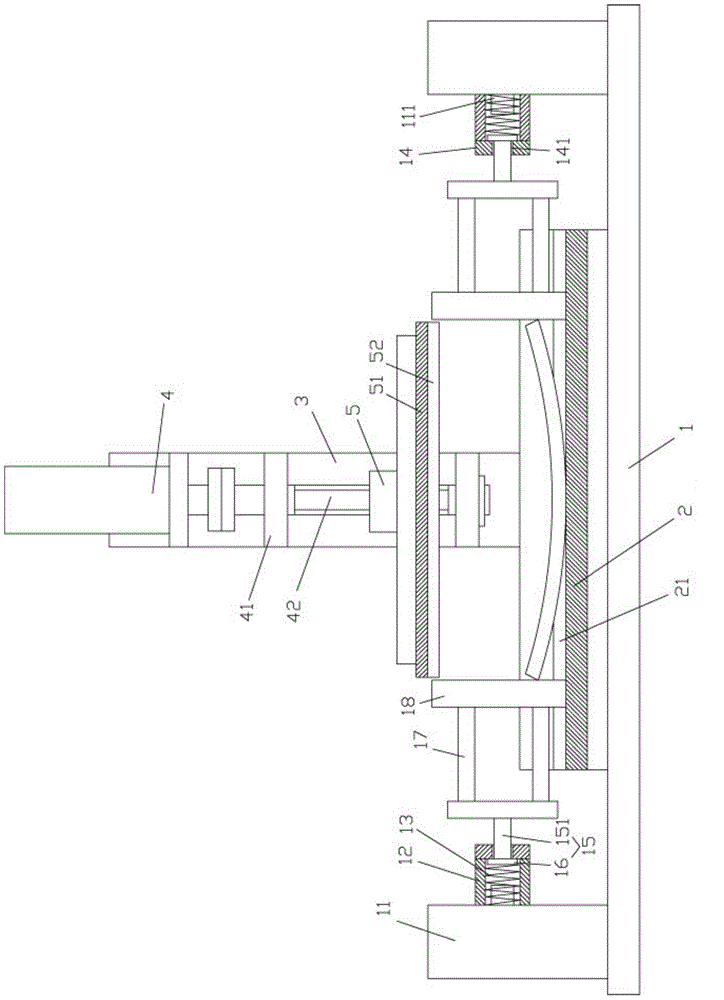

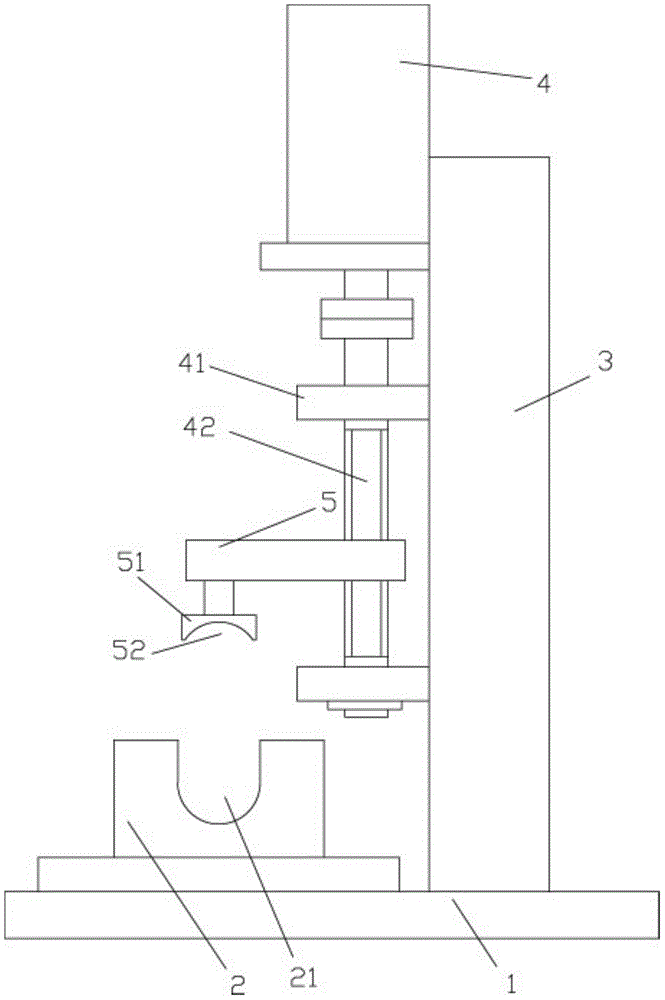

[0014] Examples, see e.g. Figures 1 to 2 As shown, a construction steel pipe straightening device includes an underframe 1, a steel pipe placement block 2 is fixed on the underframe 1, a placement groove 21 is arranged in the steel pipe placement block 2, and a support column 3 is fixed on the underframe 1 to support The column 3 is fixed with a servo motor 4 and two support blocks 41, the two ends of the screw rod 42 are hinged on the two support blocks 41, and the upper end of the screw rod 42 protrudes from the upper support block 41 and connects with the servo motor 4 through a coupling. The output shaft of the output shaft is fixedly connected, the connecting block 5 is screwed in the screw man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com