Worm gear deviation correcting device

The technology of a deviation rectifying device and a worm gear is applied in the field of deviation adjusters, which can solve the problem that the deviation adjuster cannot effectively rectify the deviation of the conveyor belt, and achieve the effects of stable overall performance, long service life and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

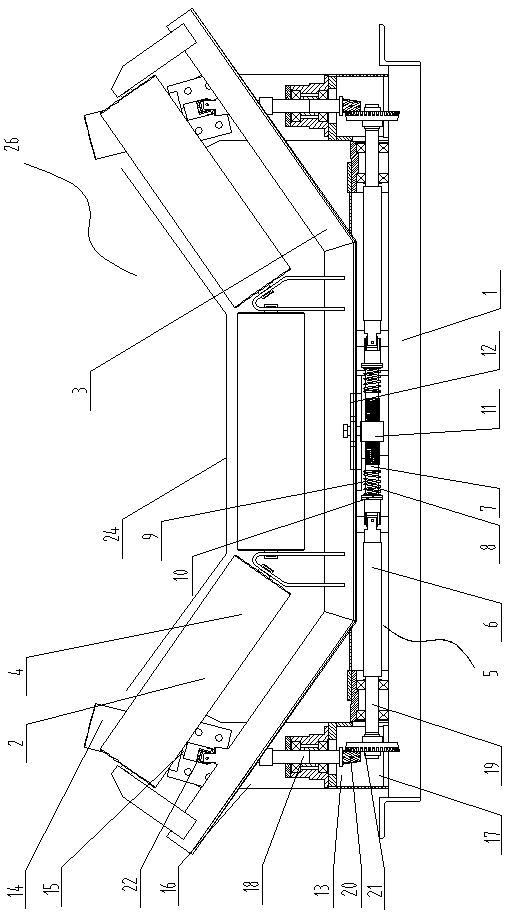

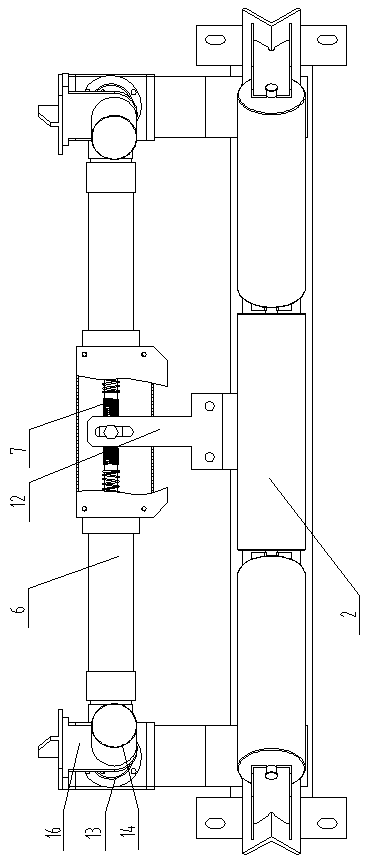

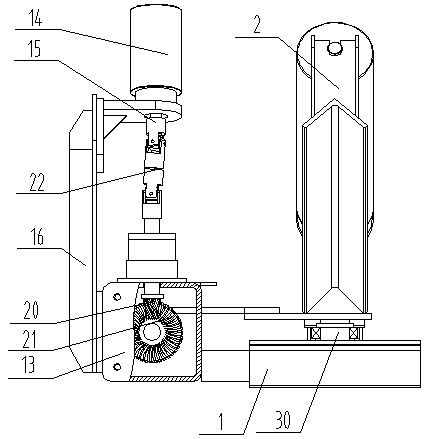

[0023] Such as Figure 1-3 As shown, the present invention discloses a worm gear and worm deviation correcting device 26, including a frame 1, on which an idler assembly 2 is arranged, on which an idler assembly 2 supports a conveyor belt 24, and the idler assembly 2 includes an idler bracket 3 and rotate the idler roller 4 mounted on the idler bracket 3, the center of the bottom of the idler assembly 2 is installed on the frame 1 through the bracket rotation shaft 5 through the belt seat bearing 30, and the idler assembly 2 is on one side along the conveying direction A transmission rod 5 is provided, and the transmission rod 5 is parallel to the width direction of the frame 1. The transmission rod 5 includes two transitional connecting rods 6 and a screw section 7 connected between the two transitional connecting rods 6. Both ends are polished rod sections 9, and springs 8 are respectively inserted on the polished rod sections 9, and spring limit retaining rings 10 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com