External thread turning fixture of thin-wall sleeve

A technology of thread turning and thin-wall sleeves, which is applied in the field of mechanical processing, can solve problems affecting dimensional accuracy and shape tolerance, weak strength, vibration deformation, etc., and achieve the effect of simple and compact structure, convenient mass production, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

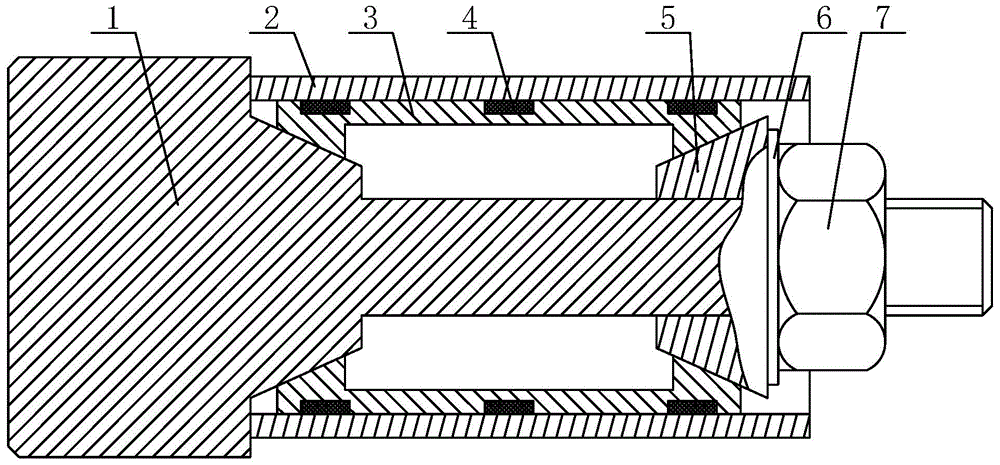

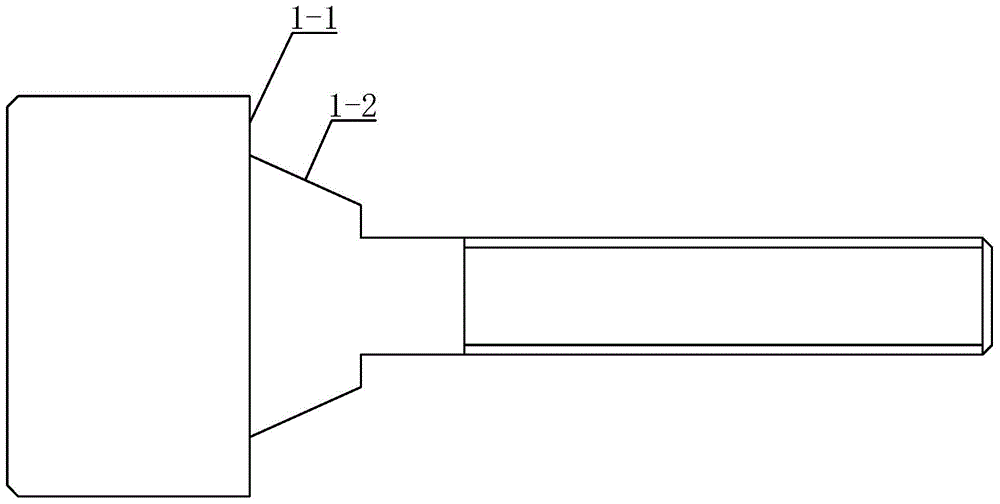

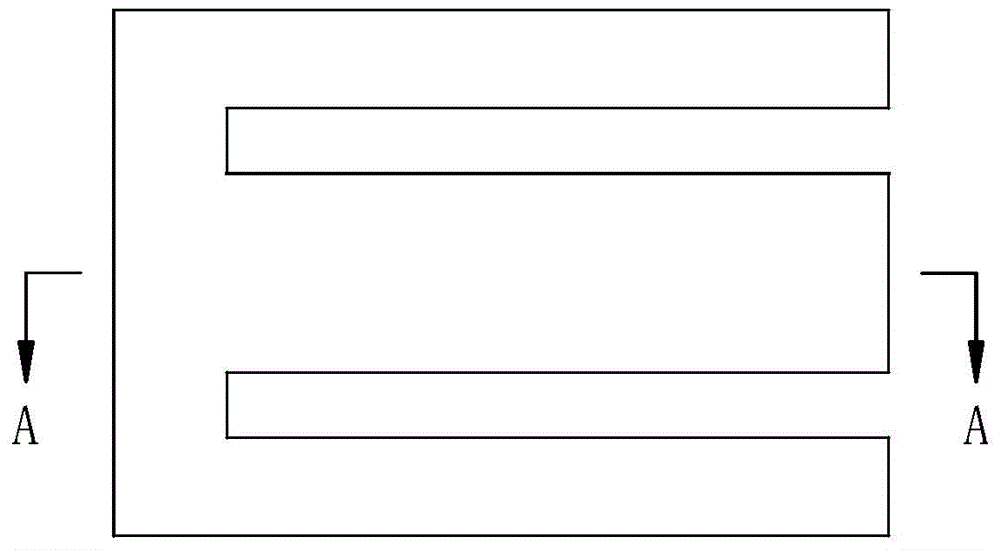

[0022] Such as Figure 1-Figure 4 A thin-walled sleeve external thread turning fixture shown includes a stepped threaded shaft 1, an elastic expansion sleeve 3 and a taper sleeve 5; one end of the stepped threaded shaft 1 is provided with a positioning table 1 for positioning the workpiece 2 to be processed -1, on the side of the positioning platform 1-1, the stepped threaded shaft 1 is provided with an outer tapered surface 1-2 having the same taper as the taper sleeve 5, and the stepped threaded shaft 1 is set with a The elastic expansion sleeve 3 that pushes against and supports the workpiece 2 to be processed is provided with a taper sleeve 5 between the elastic expansion sleeve 3 and the stepped threaded shaft 1, and the inner sides of both ends of the elastic expansion sleeve 3 are provided with The inner tapered surface 3-1 having the same taper as the taper sleeve 5, the outer side of the elastic expansion sleeve 3 is provided with a plurality of mounting grooves 3-2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com