Powered pin puller

A pin puller and power technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high input cost, complex structure, bulky volume, etc., and achieve the effect of reducing production cost, low price, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The power pin puller of the present invention will be described in detail below with reference to the accompanying drawings.

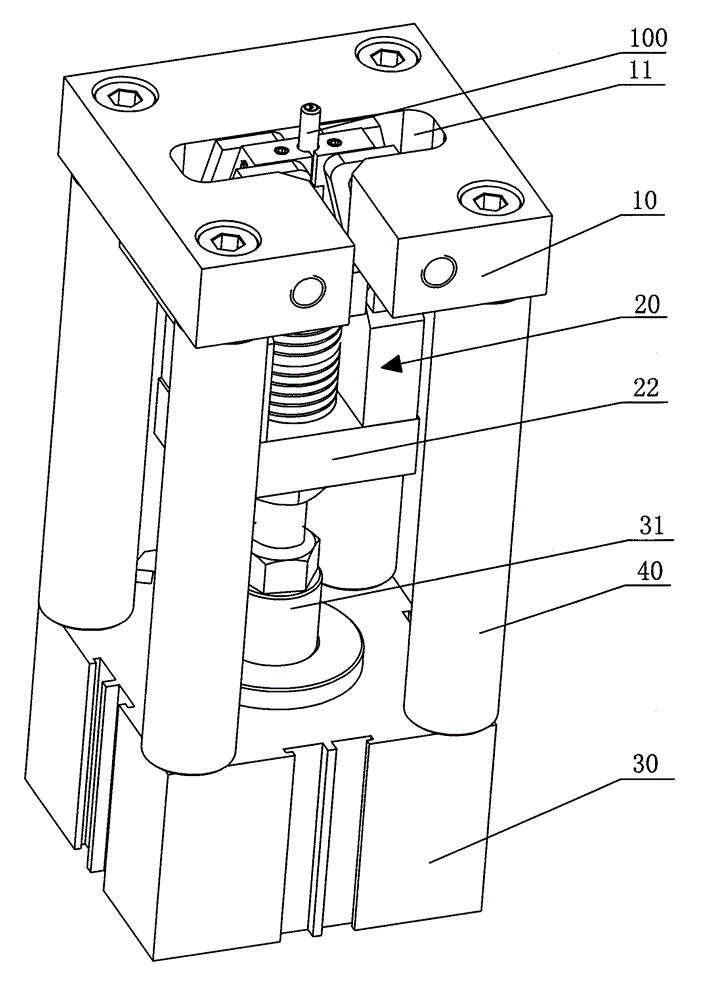

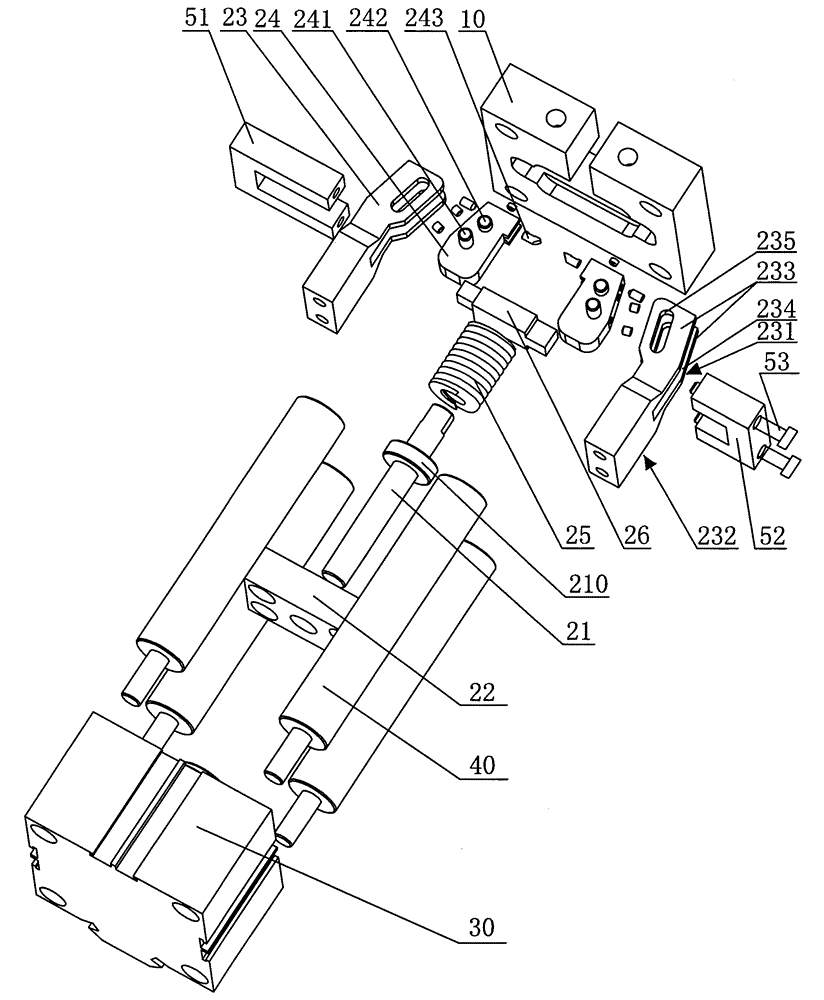

[0015] Such as figure 1 As shown, the power pin puller of the present invention includes a positioning plate 10, a sliding pin pulling device 20, and a power device 30. The sliding pin pulling device 20 is located between the positioning plate 10 and the power device 30, and the positioning plate 10 is connected by four pillars 40. on the power unit 30.

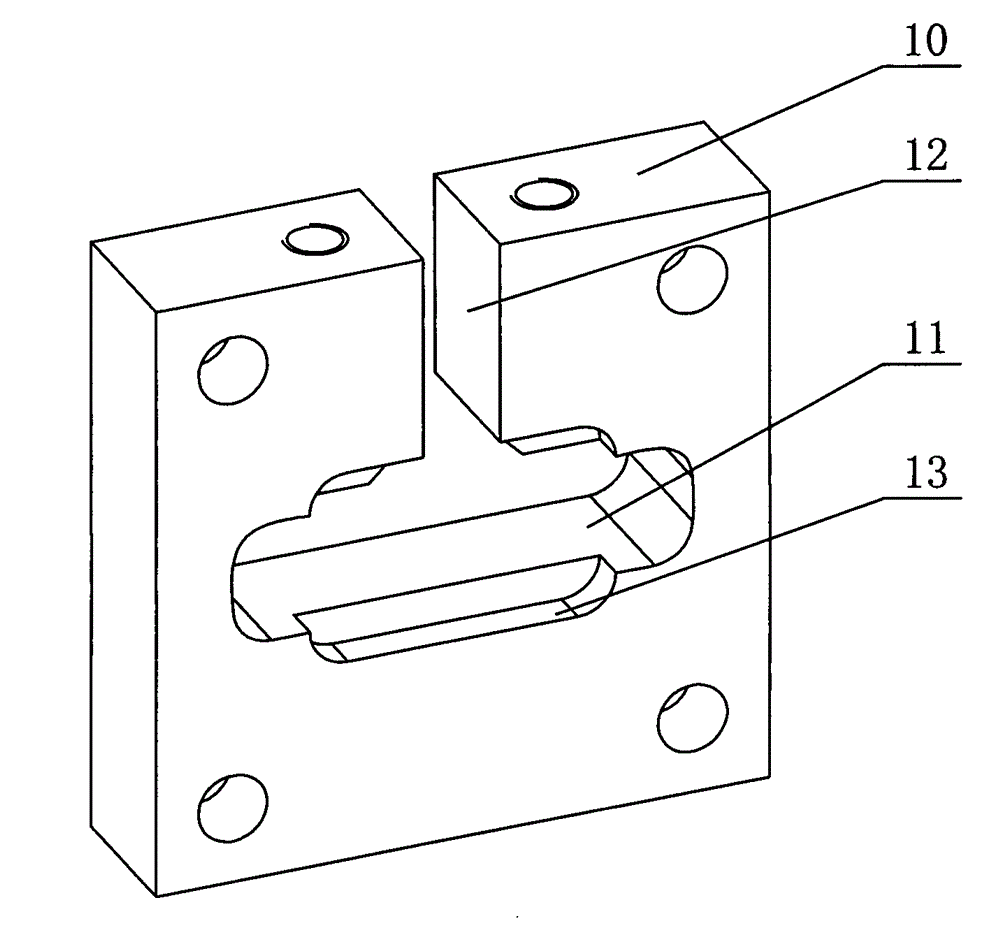

[0016] Such as figure 2 As shown, the positioning plate 10 is provided with a rectangular hole 11 and a long and narrow opening 12 , which communicate with each other. The extending direction of the opening 12 is perpendicular to the wall of the rectangular hole 11 . The rectangular hole 11 allows the positioning pin 100 to extend into the sliding pin pulling device 20 through it; the opening 12 is convenient for the operator to take out the pulled out positioning pin 100 . A pair of rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com