Hydraulic driving type multi-station milling fixture

A driven, multi-station technology, applied in the field of mechanical processing, can solve the problems of long processing preparation time, low clamping efficiency, high labor intensity, etc., and achieve the effect of low production cost, high work efficiency, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

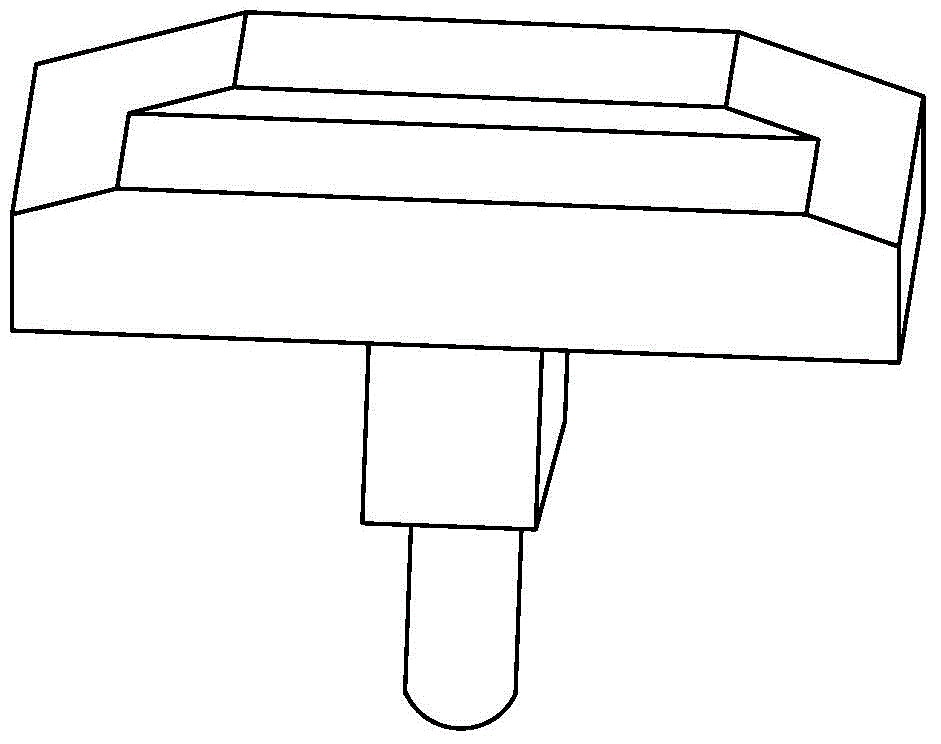

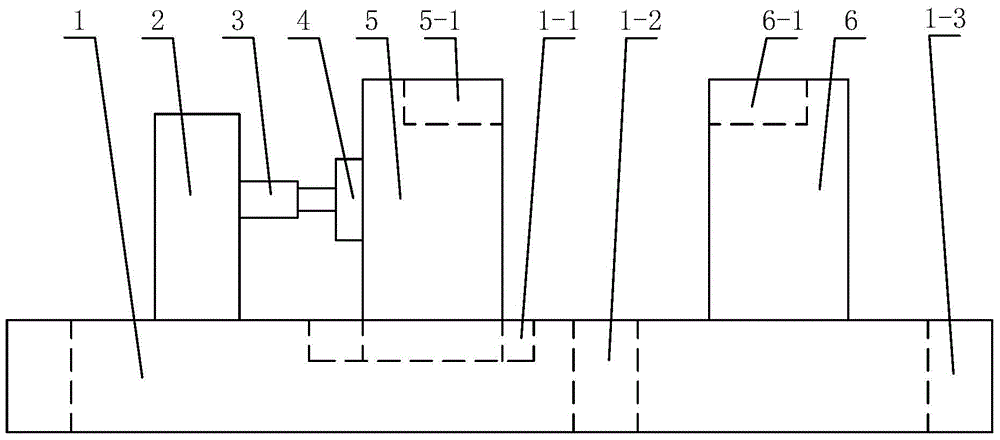

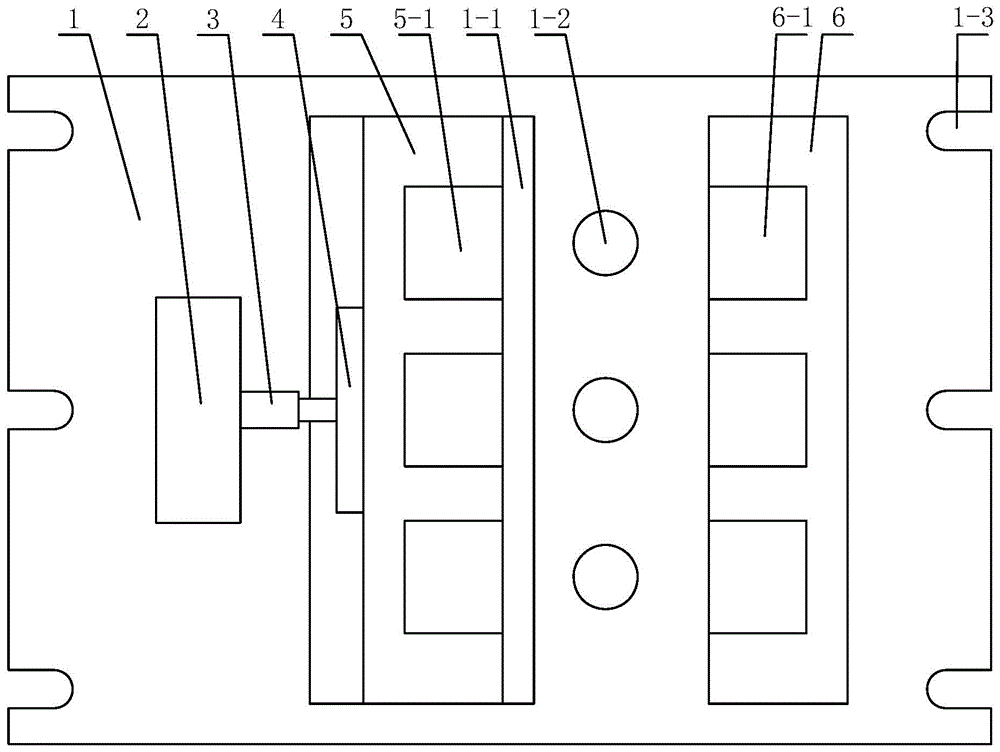

[0022] Such as figure 2 and image 3 The shown hydraulically driven multi-station milling fixture includes a rectangular base 1, a plurality of installation grooves 1-3 are arranged on both sides of the rectangular base 1, and a hydraulic cylinder 3 is also included for installing the hydraulic cylinder. 3 and the positioning and pressing slider 5 for positioning and pressing the T-shaped workpiece 7 to be processed; the upper side of the rectangular base 1 is provided with a chute 1-1, and one side of the rectangular base 1 is fixed There is a mounting frame 2, a hydraulic cylinder 3 is fixedly arranged on the mounting frame 2, and a push plate 4 is fixedly provided at the end of the piston rod of the hydraulic cylinder 3, and the push plate 4 is slidingly arranged on the chute 1- The positioning and pressing slider 5 in 1 is fixedly connected, the upper side of the positioning and pressing slider 5 is provided with at least two positioning grooves 5-1, and the other side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com