Hot forming machine of plastic cup cover

A thermoforming machine, plastic cup technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of material tearing, high viscosity, unable to complete the molding work, etc., to avoid adhesion phenomenon, save manual physical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

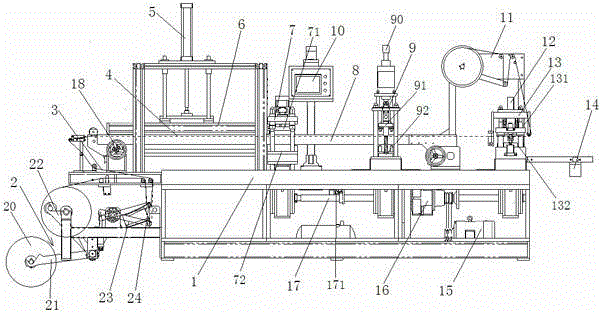

[0024] figure 1 As shown, it relates to a plastic cup lid thermoforming machine, including a frame 1, which is provided with a conveying unit 4 for conveying a plastic sheet 3, a power drive unit for driving each device to work, and a unit for unifying Regulate the panel control unit 10 of each device; the input side to the output side of the conveying unit 4 are sequentially provided with: an unwinding device 2, which is used to unwind the plastic coil to form a plastic sheet 3; an adjustable chain clip mechanism 18, which is used to hang the plastic sheet 3 above the conveying unit 4; oven heating device 6, which is used to heat and soften the plastic sheet 3; mold forming device 7, which is used to process the plastic sheet 3 into Cup lid-shaped plastic film; punching device 9, which is used for punching the cup lid-shaped plastic film; punching device 13, which is used to make the cup lid-shaped plastic film after the punching process into a single-piece cup The finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com