System and method for image receiving surface treatment in an indirect inkjet printer

An inkjet printer, image receiving technology, applied in printing devices, printing, etc., can solve the problems of short wear and aging, ink droplet diffusion, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

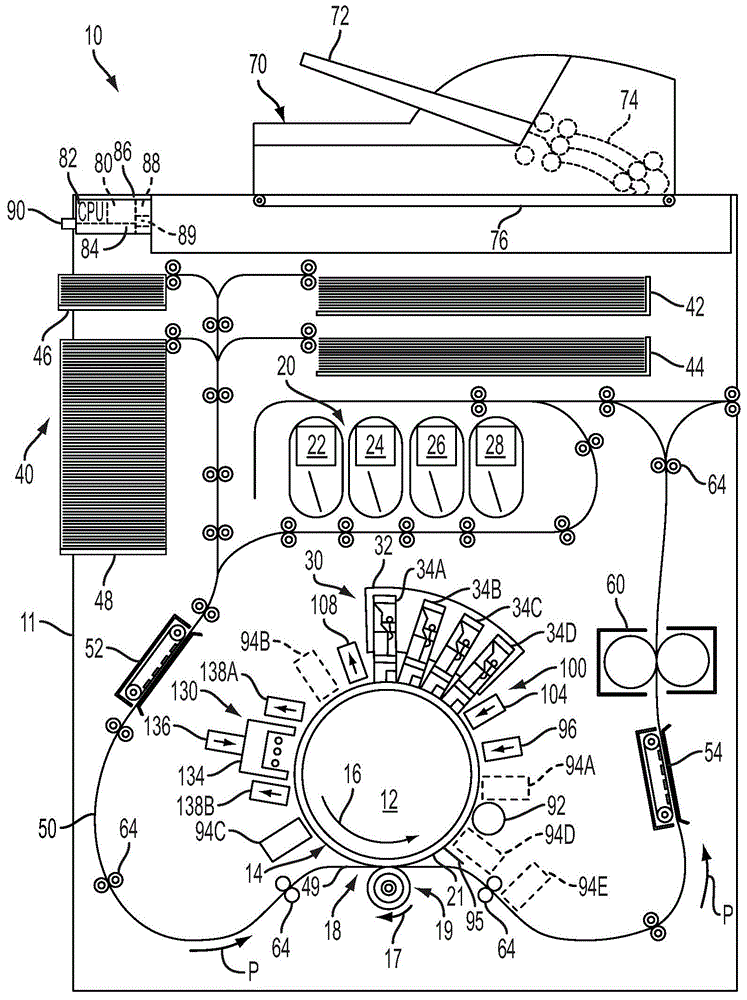

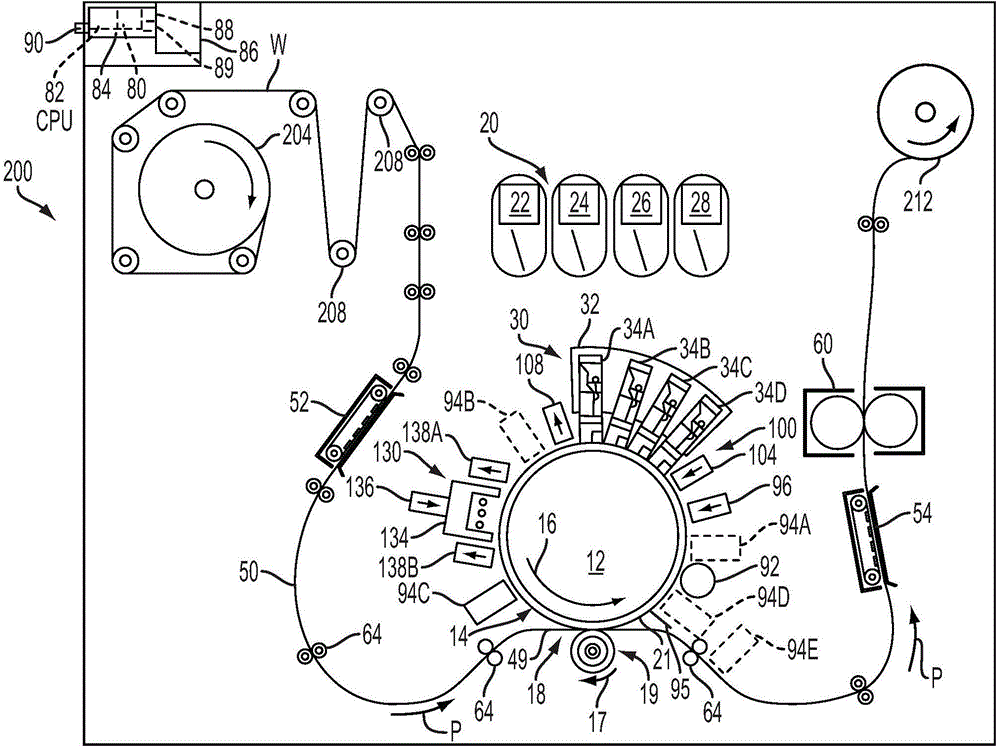

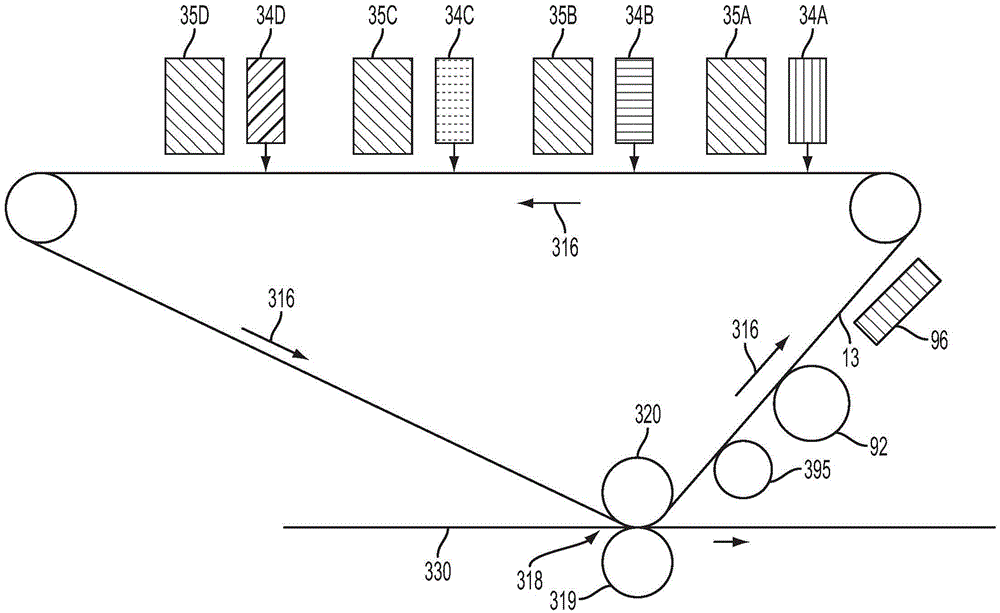

[0020] As used herein, the term "hydrophilic" means a composition or compound that attracts water molecules or other solvents used in aqueous inks. As used herein, the reference to hydrophilic composition refers to the liquid carrier carrying the hydrophilic absorbent. Examples of liquid carriers include, but are not limited to, liquids, such as water or alcohol, that carry the dispersion, suspension or solution of the absorbent. The dryer then removes a portion of the liquid carrier and the remaining solid or gel phase absorbent has high surface energy to absorb a portion of the water in the aqueous ink drop, while allowing the colorant in the aqueous ink drop to spread on the surface of the absorbent. As used herein, the reference to the dry layer of the absorbent refers to the placement of the hydrophilic compound after all or a substantial portion of the liquid carrier has been removed from the composition by a drying process. As described in more detail below, indirect i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com