Steel ball evenly feeding and discharging groove

A technology of discharge chute and steel ball, which is applied in the direction of transportation, packaging, and slideway, etc., which can solve the problems of underutilization of the sorting screen and missed selection of steel balls, and achieve the effect of avoiding bruises and missed selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

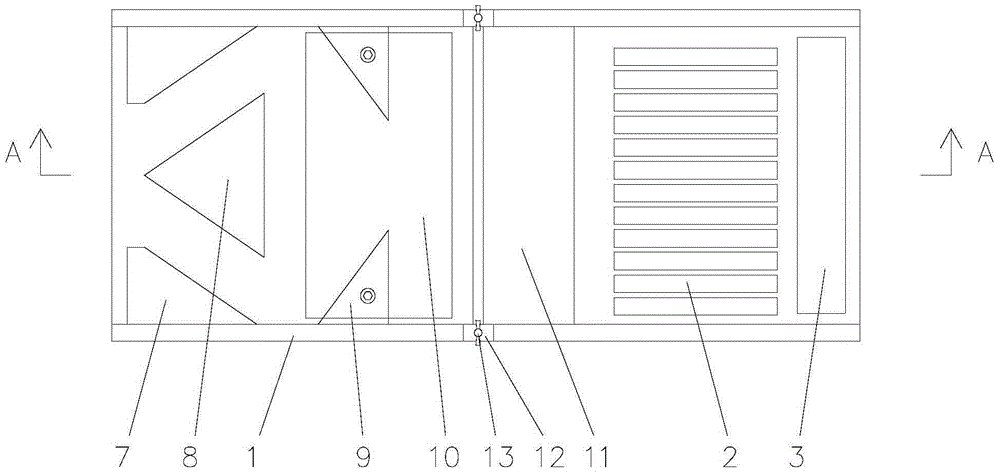

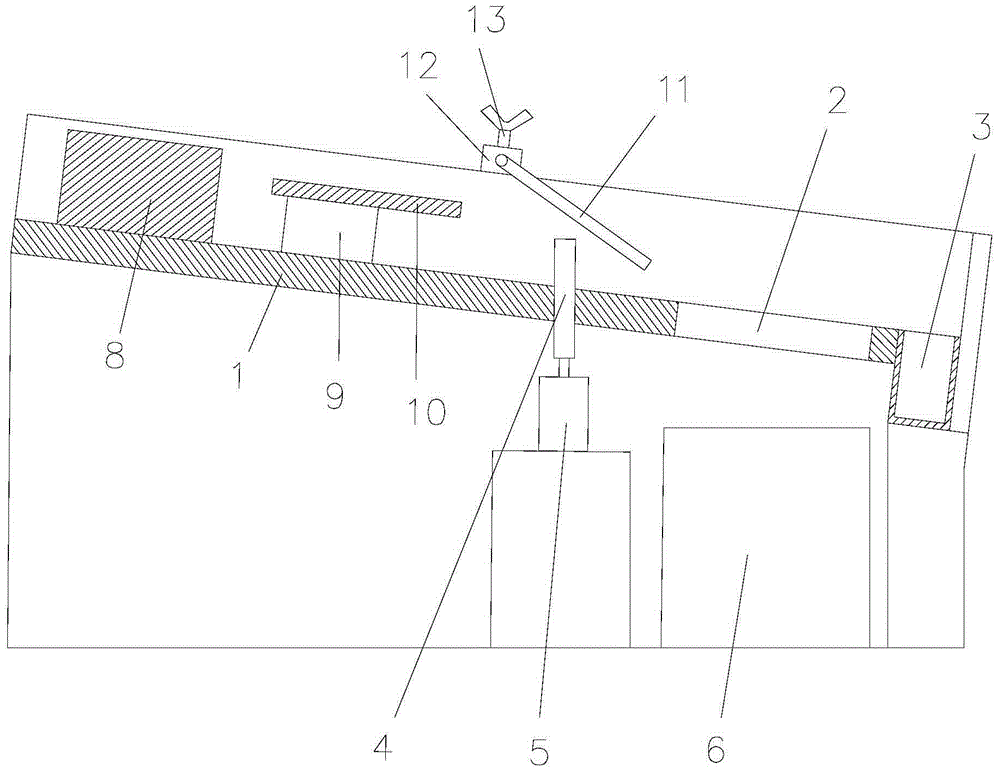

[0015] As shown in the figure, the discharge chute of this embodiment includes a chute for uniform discharge of steel balls, including a chute body 1, in which a steel ball buffer device, a retractable material door device, and a sorting screen are arranged in sequence from the feed end to the discharge end. 2 and the unqualified ball receiving trough 3, the telescopic material door device includes a material door 4 arranged in the bottom of the tank body along the horizontal direction and a lifting cylinder 5 that drives the material door to move up and down, and the material door and the bottom of the tank body slide up and down In cooperation, the lower part of the sorting screen is provided with a normal ball receiving tank 6 .

[0016] In this embodiment, the steel balls are evenly discharged into the discharge trough, which uses the cylinder to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com