Low-abrasion windproof sealing-tape machine

A belt conveyor, low-wear technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of belt deviation, belt breakage, delay in transportation work, etc., to extend the belt and rollers, and prevent waste of resources. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

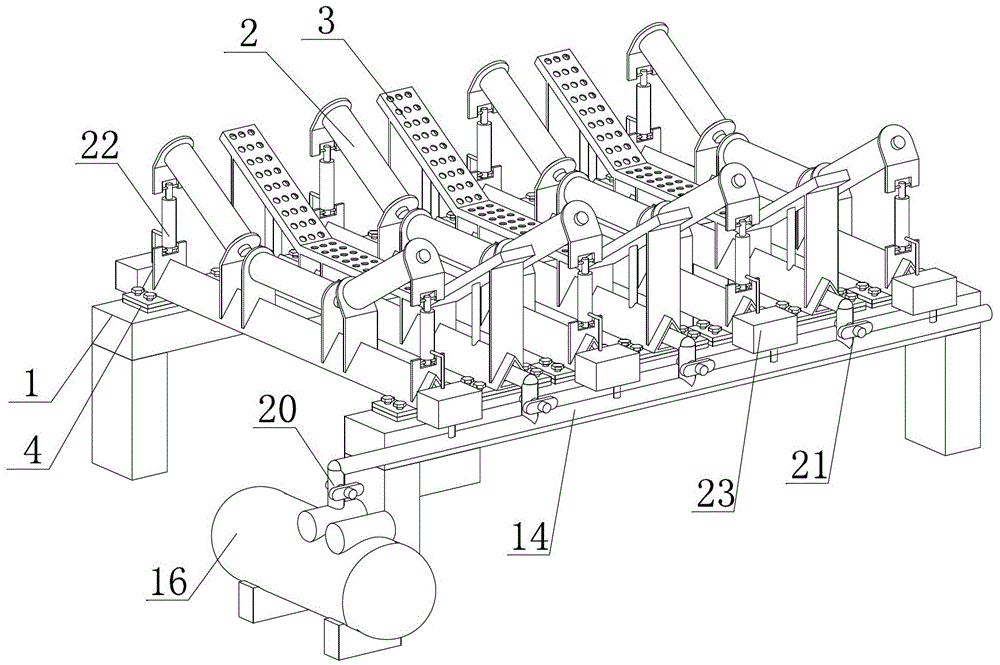

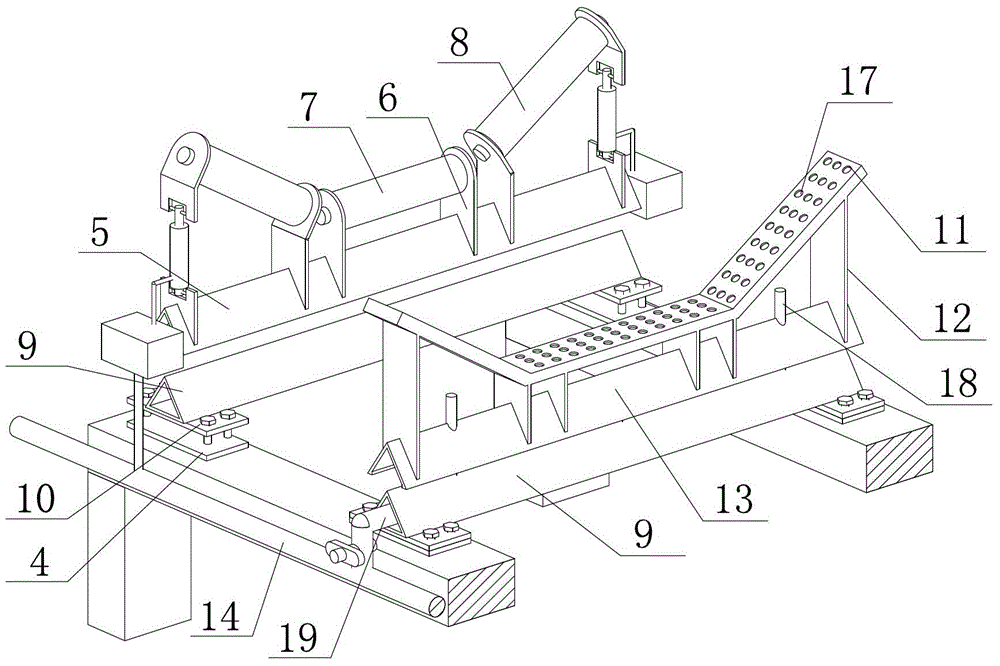

[0019] Embodiment 1 of the present invention: as figure 1 As shown in the figure, a low-wear windproof tape machine includes a roller group bracket 1 and a grooved roller group 2. The grooved roller group 2 is evenly distributed on the roller group bracket 1, and any two adjacent grooved rollers There is a group of air jet pallets 3 between the groups 2; the bottom of the trough roller group 2 and the air jet pallet 3 is equipped with a shock absorber 4; one side of the roller bracket 1 is provided with a general gas delivery pipe Road 14, each air jet pallet group 3 is connected with the total gas delivery pipeline 14, and the total gas delivery pipeline 14 is connected with the air pump 16; each trough idler group 2 is provided with a cylinder 22, the said The cylinder 22 is connected with the main gas delivery pipeline 14 through an electric valve 23 . A valve A20 is provided at the connecting end of the total gas delivery pipeline 14 and the air pump 16; each branch air p...

Embodiment 2

[0023] Embodiment 2 of the present invention: as figure 1 As shown in the figure, a low-wear windproof tape machine includes a roller group bracket 1 and a grooved roller group 2. The grooved roller group 2 is evenly distributed on the roller group bracket 1, and any two adjacent grooved rollers There is a group of air jet pallets 3 between the groups 2; the bottom of the trough roller group 2 and the air jet pallet 3 is equipped with a shock absorber 4; one side of the roller bracket 1 is provided with a general gas delivery pipe Road 14, each air jet pallet group 3 is connected with the total gas delivery pipeline 14, and the total gas delivery pipeline 14 is connected with the air pump 16; each trough idler group 2 is provided with a cylinder 22, the said The cylinder 22 is connected with the main gas delivery pipeline 14 through an electric valve 23 . A valve A20 is provided at the connecting end of the total gas delivery pipeline 14 and the air pump 16; each branch air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com