Shaft machining conveyer

A conveying device and shaft technology, applied in conveyors, transportation and packaging, metal processing equipment, etc., can solve the problems of affecting quality, increasing scrap rate, and high maintenance costs, and achieve the effects of saving maintenance costs, convenient replacement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

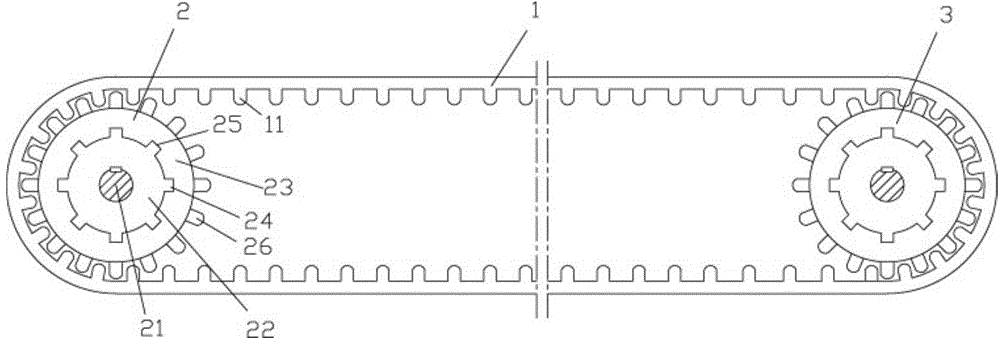

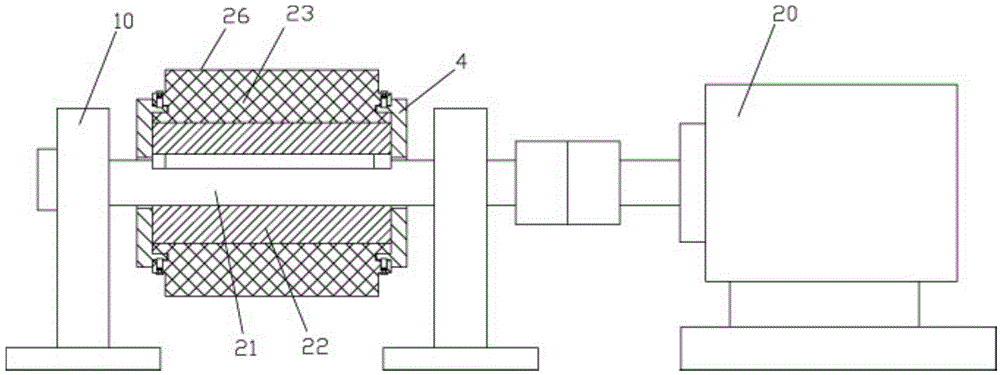

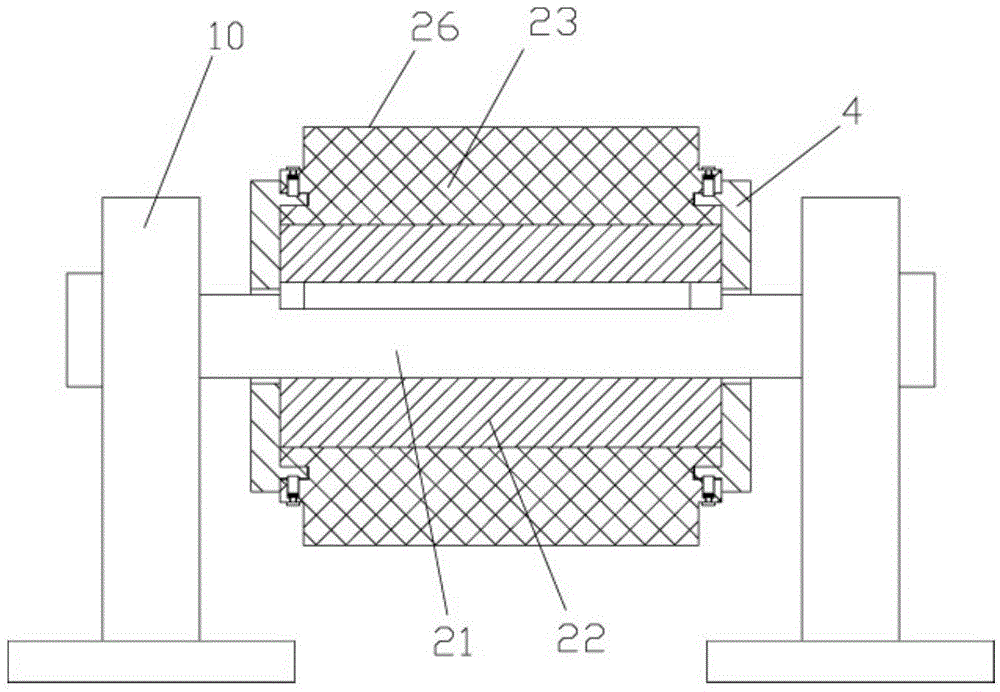

[0022] Examples, see e.g. Figures 1 to 5 As shown, a conveying device for rotating shaft processing includes a conveying belt 1, and the conveying belt 1 is tensioned on the main driving wheel 2 and the driven driving wheel 3. The main driving wheel 2 and the driven driving wheel 3 have the same structure, and they include a rotating shaft 21. The central wheel 22 and the outer rotating wheel 23, the rotating shaft 21 is fixed in the central through hole of the central wheel 22 through a key connection, the two ends of the rotating shaft 21 protrude from the central wheel 22, and the outer wall of the central wheel 22 has a plurality of protrusions 24 The inner side wall of the outer rotating wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com