Electrical control system of carbon electrode paste conveying system

A technology of electrical control system and conveying system, applied in the direction of conveyor control device, conveyor, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

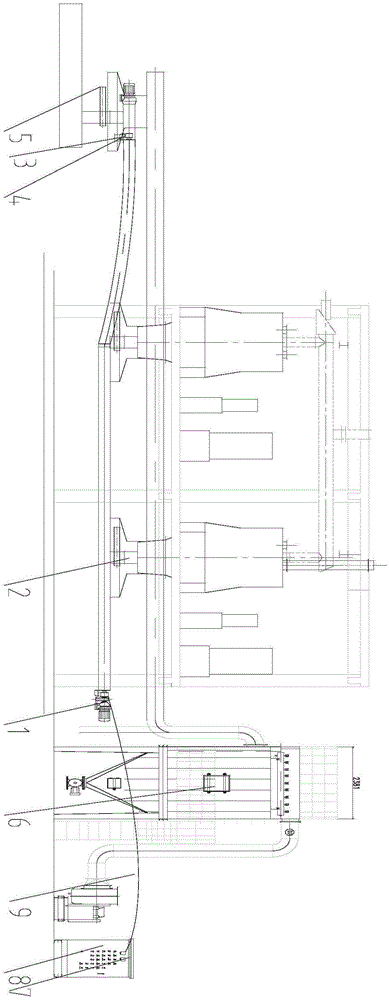

[0010] Embodiment 1: the following combination figure 1 to tell An electrical control system for a carbon electrode paste delivery system The working process:

[0011] The present invention relates to an electrical control system of an electrical control system of a carbon electrode paste conveying system, comprising a circular tube type conveyor motor 1 for conveying paste, a solenoid valve 2 of a pneumatic valve for conveying paste, an electromagnetic valve 3 of an oil pump for an unloading device, and a Paste device oil cylinder solenoid valve 4, conveyor belt out paste pneumatic valve solenoid valve 5, dust removal system electrical control system 6, PLC programmable controller 7, low-voltage control cabinet 8, cable 9, is characterized in that the above-mentioned carbon The PLC programmable controller 7 of the electrical control system of the plain electrode paste conveying system is installed in the low-voltage control cabinet 8, and controls the motor 1 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com