Steel strip coil receiving device

A technology of material receiving device and steel strip coil, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc., which can solve the problems of high maintenance frequency and easy damage, so as to reduce maintenance frequency, prolong service life, slow down The effect of lateral impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

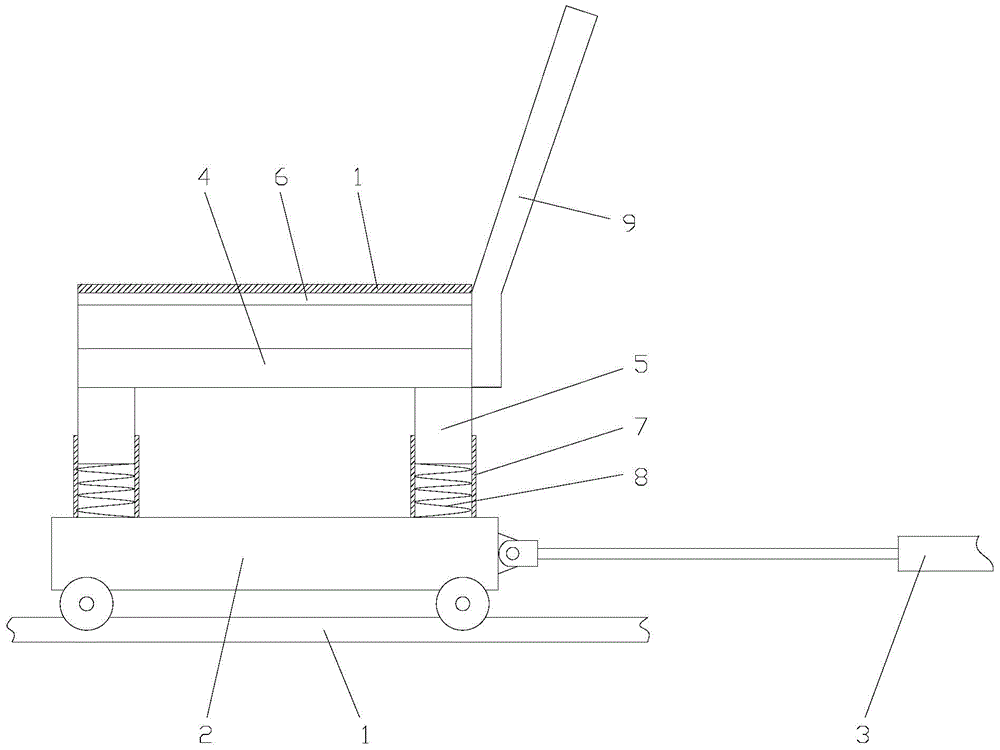

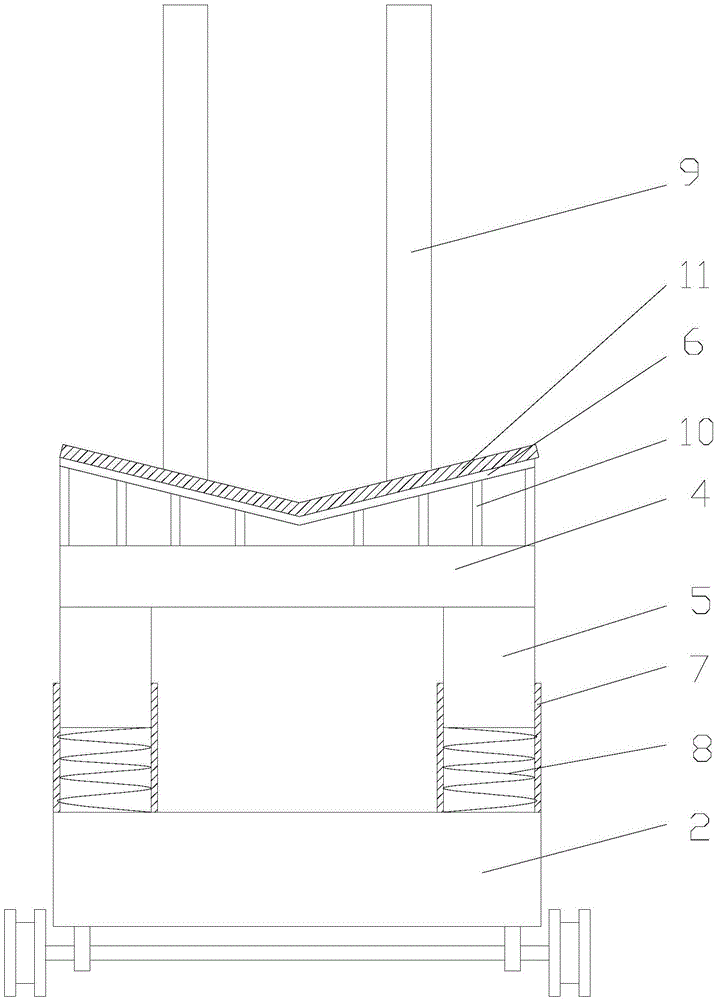

[0014] As shown in the figure, the steel strip coil receiving device of this embodiment includes a track 1, a car body 2 arranged on the track, and a cylinder 3 that drives the car body to move along the track, and also includes a receiving hopper, and the receiving hopper includes a bottom plate 4 , the guide column 5 fixed on the lower part of the base plate and the V-shaped plate 6 fixed on the upper part of the base plate, the car body is provided with a sleeve 7 that slides up and down with the guide column, and a damping spring 8 is arranged in the sleeve, The end of the car body is provided with a material stopper 9 for placing the steel strip roll overturned.

[0015] In this embodiment, the steel strip coil receiving device is provided with a shock absorbing spring between the base plate and the car body. When the steel strip coil falls on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com