Rapid-clamping rocking handle and lifting device with same

A lifting device and fast technology, applied in the field of lifting device and fast clamping crank handle, can solve problems such as personal injury, sudden drop of lifting items without consideration, crank handle falling off, etc., to achieve convenient use and avoid heavy objects Sudden drop, quick clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

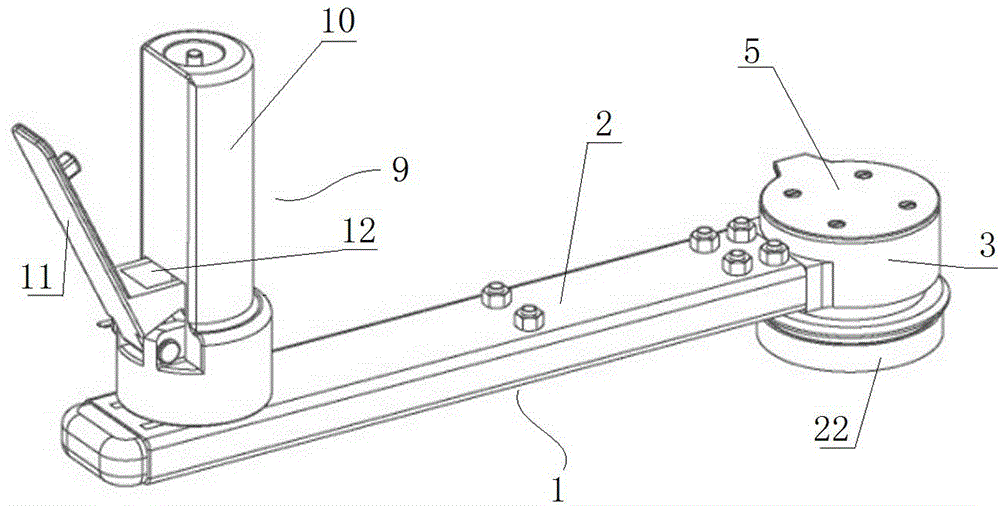

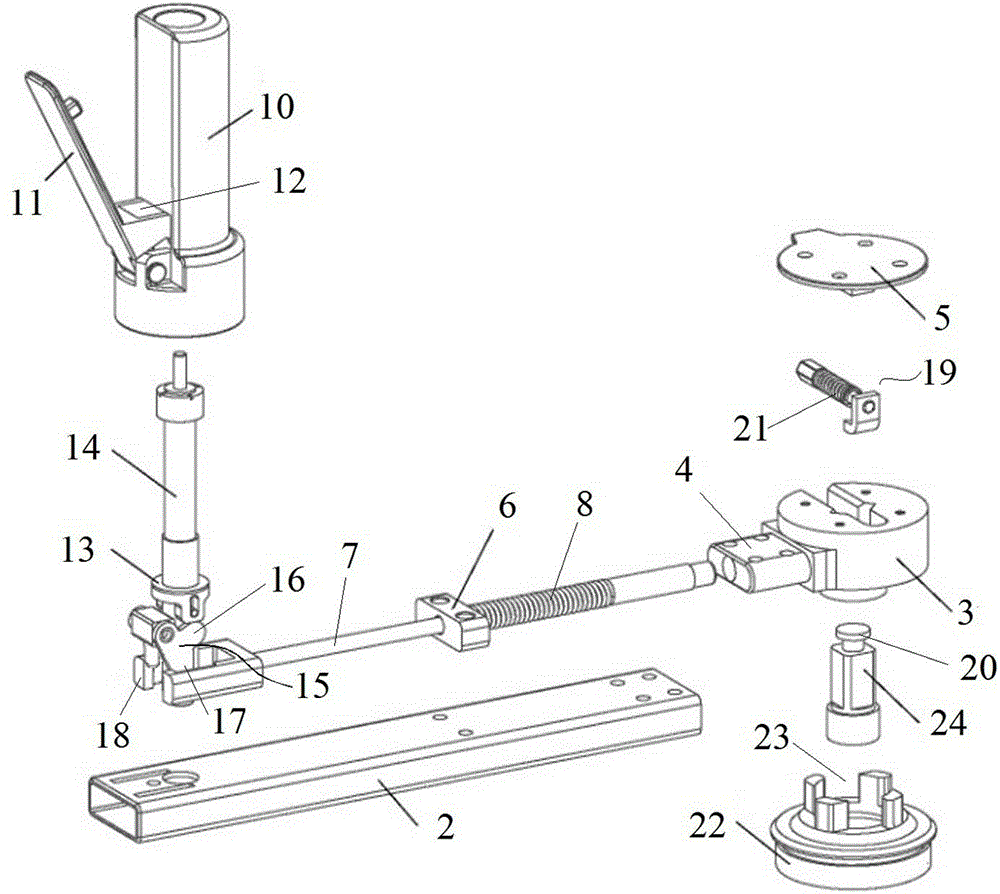

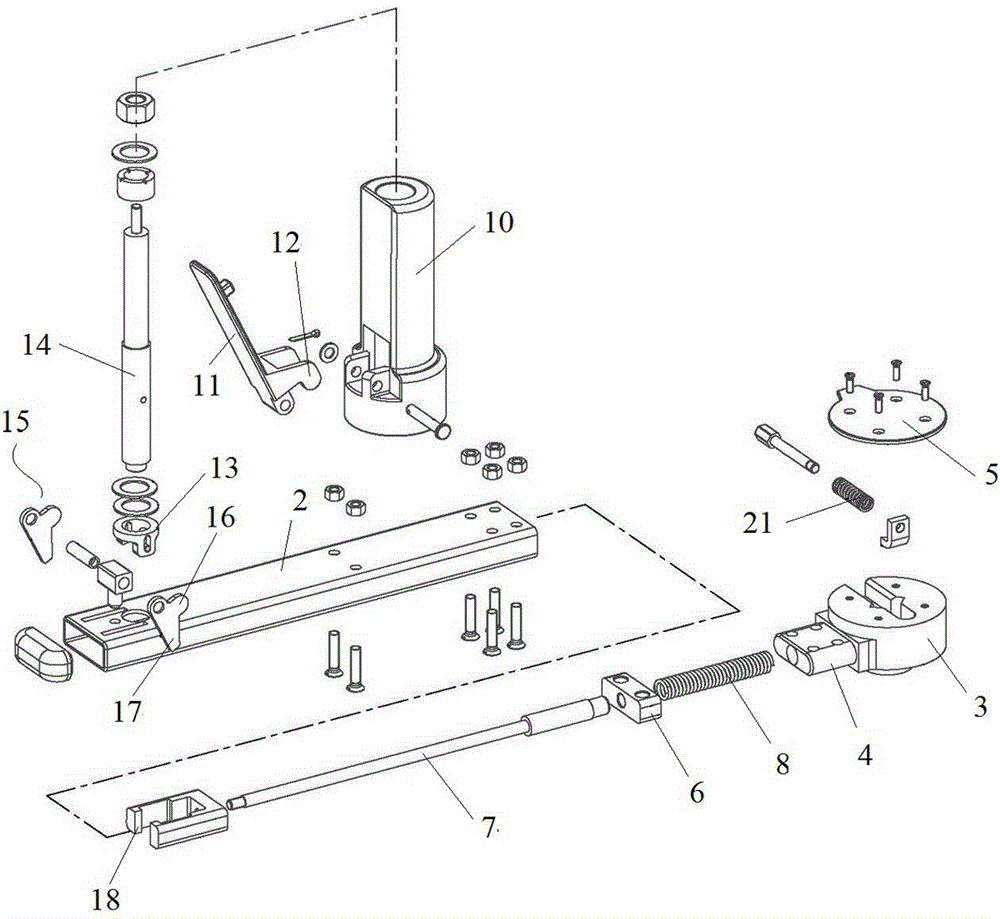

[0020] An embodiment of the fast clamping handle in the present invention is as Figure 1~Figure 3 As shown, it is a fast clamping handle used on a small lifting device. The lifting input shaft of the lifting device is fixedly connected with an input shaft 24 with a square shaft section. The fast clamping handle includes a sleeve for Set on the input shaft 24 and indirect transmission connection with the hoisting input shaft of the hoisting device to drive the power transmission handle 1 that the hoisting input shaft rotates, the anti-reverse end cover 22 for fixed connection with the main body of the hoisting device and the Operating handle 9 on the power transmission handle 1.

[0021] Four protrusions protrude from the end surface of the anti-reverse end cap 22 , and each protrusion is arranged at intervals along the circumferential direction to form stop grooves 23 uniformly distributed along the circumferential direction. The force transmission handle 1 includes a force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com