Quenching sensor with follow-up rotation for quenching continuous curved surface workpieces

A technology for quenching inductors and curved workpieces, applied in the direction of quenching devices, improvement of process efficiency, manufacturing tools, etc., can solve the problems of uneven quenching hardness, high cost, waste, etc., and achieve constant feed speed, convenient operation, and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

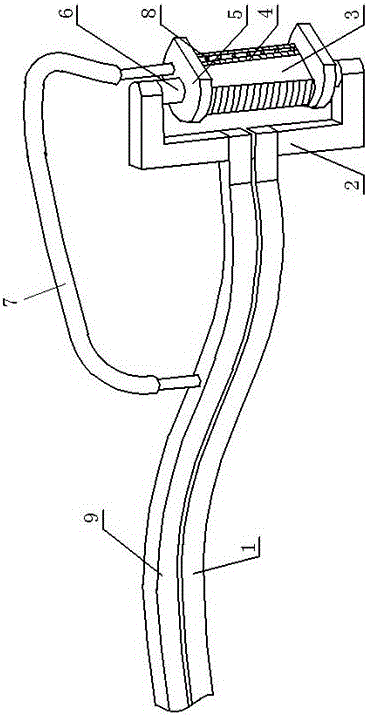

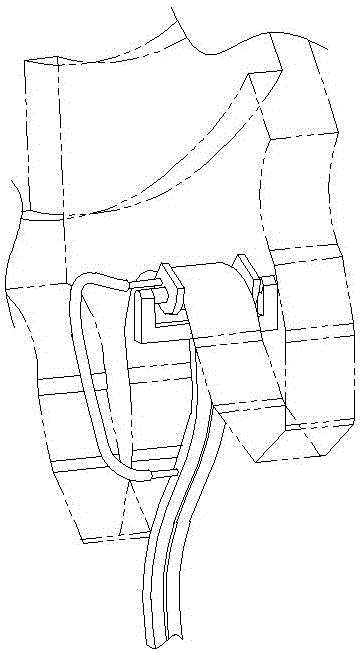

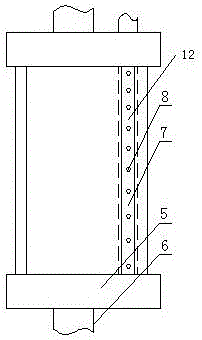

[0022] See attached Figure 1-4 The quenching inductor for continuous curved surfaces disclosed in the present invention includes an induction quenching head and a tension arm.

[0023] Tightening arm comprises tensioning arm upper arm 9 and tensioning arm lower arm 1, tensioning frame 2, rotary shaft 6. One end of the upper arm of the tension arm and the lower arm of the tension arm is connected with the frequency conversion pulse direct current power supply, and is fixed on the frame of the driving mechanism, and is driven by the driving mechanism to move. Their other ends are respectively vertically fixed with a frame body, and the two frame bodies form a tensioning frame 2 of a C-shaped structure, and the two free ends of the tensioning frame are welded and fixed to the rotary shaft respectively. The upper arm of the tensioning arm, the lower arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com