Underframe of sapphire single crystal growth furnace

A growth furnace, sapphire technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of large occupied space and height, small length and height of parts, etc., to reduce space height and improve production. Efficiency, the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The bottom frame of the sapphire single crystal growth furnace of the present invention will be further described in detail below in conjunction with the accompanying drawings.

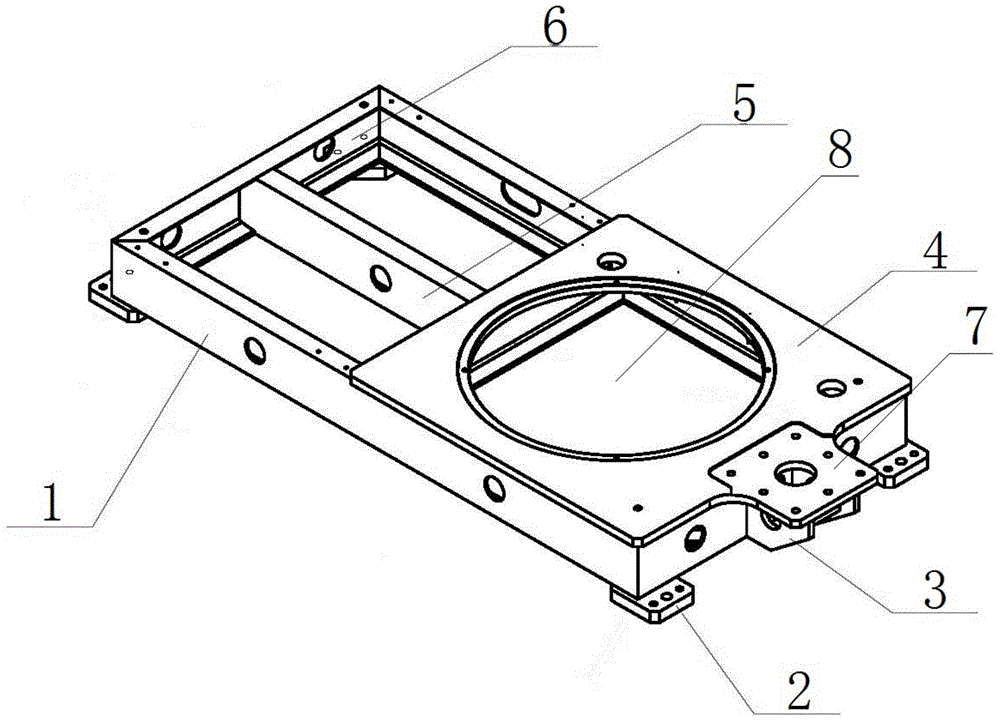

[0015] Such as figure 1 As shown, the bottom frame of the sapphire single crystal growth furnace of the present invention includes: a frame composed of main beams 1 and crossbeams 6 arranged oppositely, and the two ends of the longitudinal beams 5 are respectively connected with the inner walls of the two ends of the frame to improve the stability of the frame. stability. The main board 4 is arranged on the frame, and the main board 4 is provided with an installation hole 8 for installing the cavity part of the sapphire single crystal growth furnace on the installation plane. The mounting plate 7 is arranged on one side of the main board 4 and extends toward the outside of the frame, and is used for installing a column and can install a rotation and movement mechanism on the upper end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com