Air passage, heat-pump clothes drying device and heat-pump clothes drying control method

An air duct and clothes drying technology, which is applied to washing devices, household clothes dryers, textiles and papermaking, etc., can solve the problems of slow air temperature rise and affecting drying efficiency, so as to reduce energy consumption, improve drying efficiency, and shorten the drying time. The effect of time at normal operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

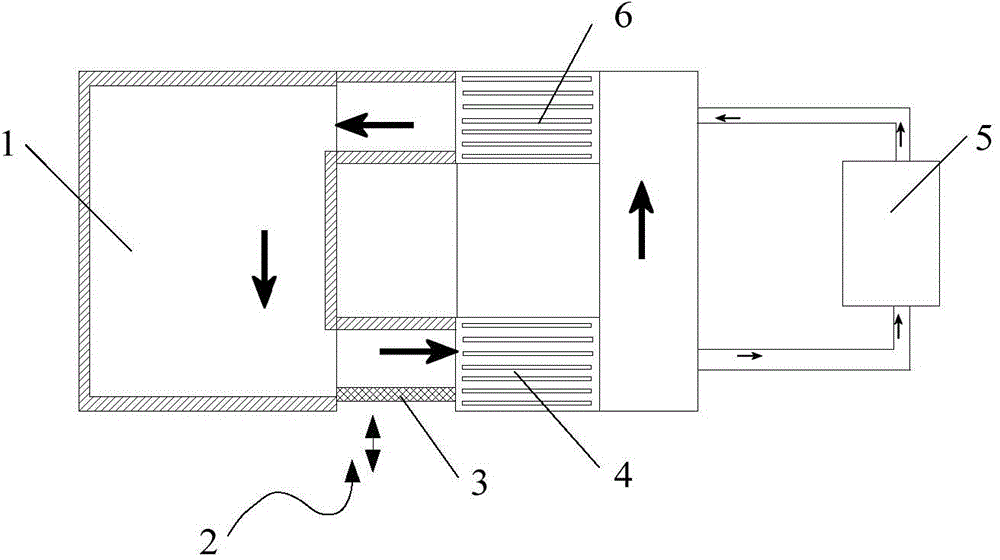

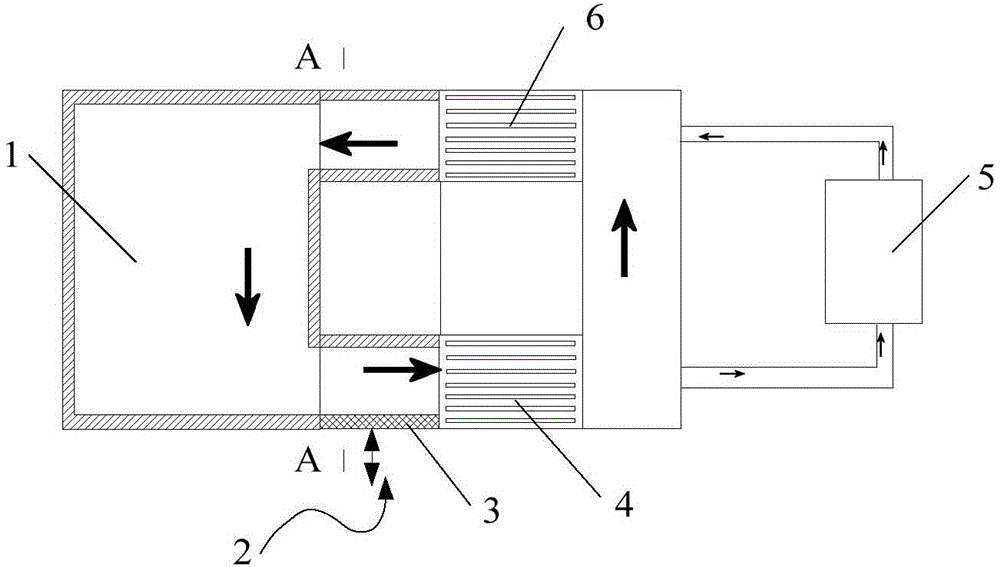

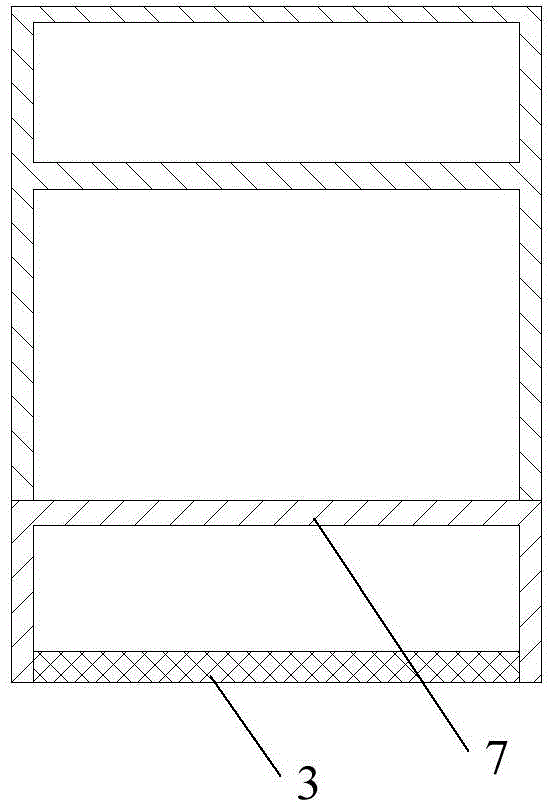

[0017] figure 1 A schematic diagram of the structure of the heat pump drying device provided by the embodiment of the present invention in the starting state of drying clothes; figure 2 A schematic diagram of the structure of the heat pump drying device provided in the embodiment of the present invention in a stable drying state. Such as figure 1 , figure 2 As shown, the air duct provided by the embodiment of the present invention includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com