Multifunctional ecological optimizing energy-saving coating and preparation method thereof

An energy-saving and multi-functional technology, applied in anti-fouling/underwater coatings, reflective/signal coatings, coatings, etc., it can solve the problems of poor stain resistance, poor decorative effect, single color, etc., and achieve enhanced stain resistance. Performance and water resistance, maintain beautiful as new, enhance the effect of cell vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

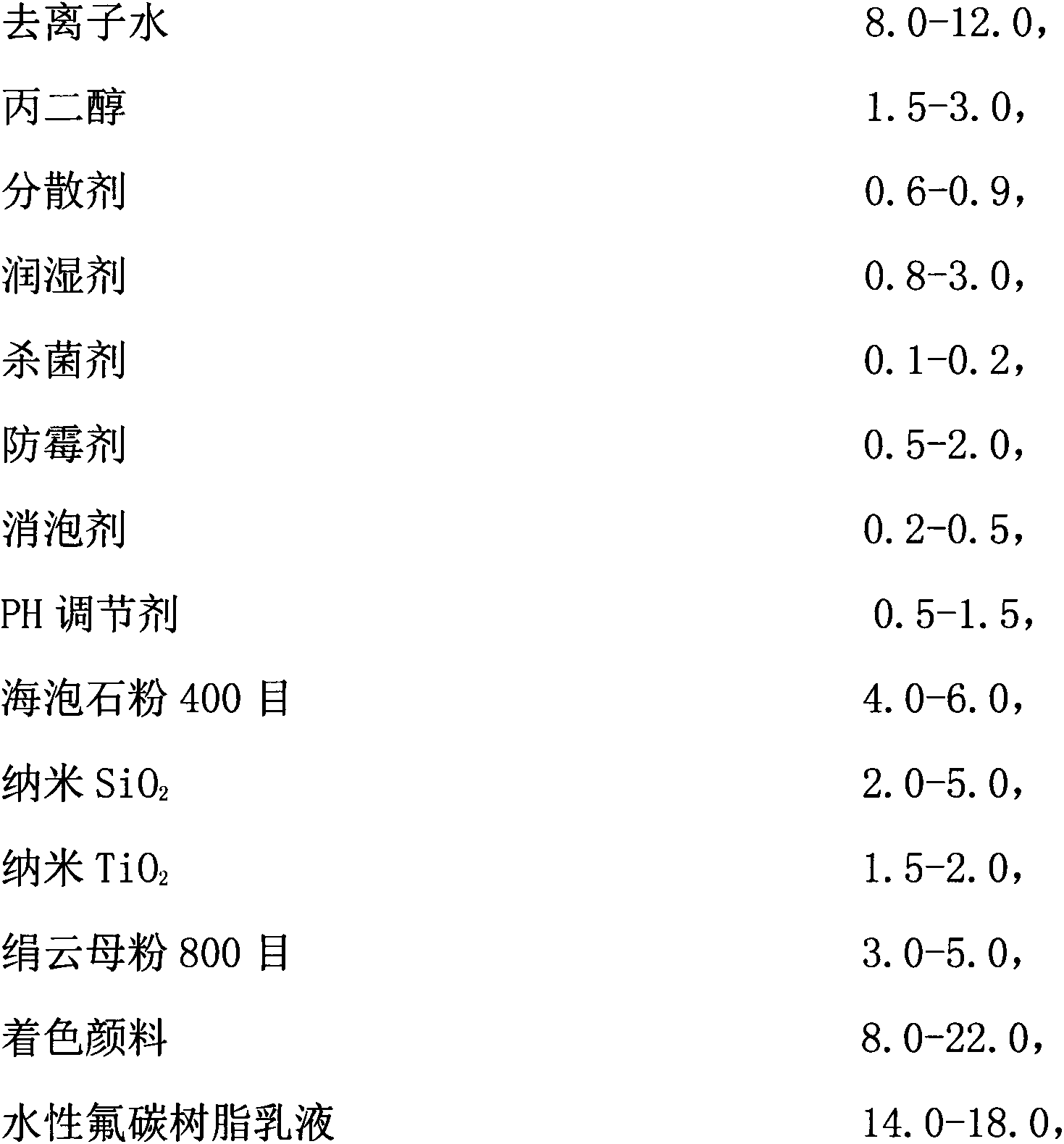

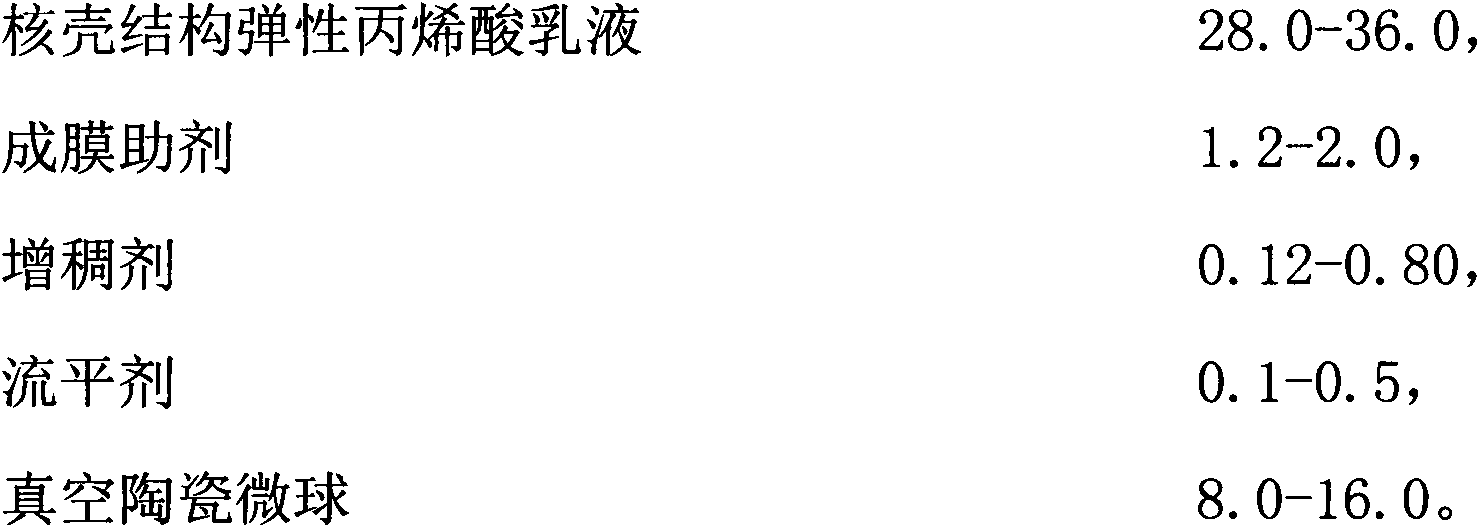

Method used

Image

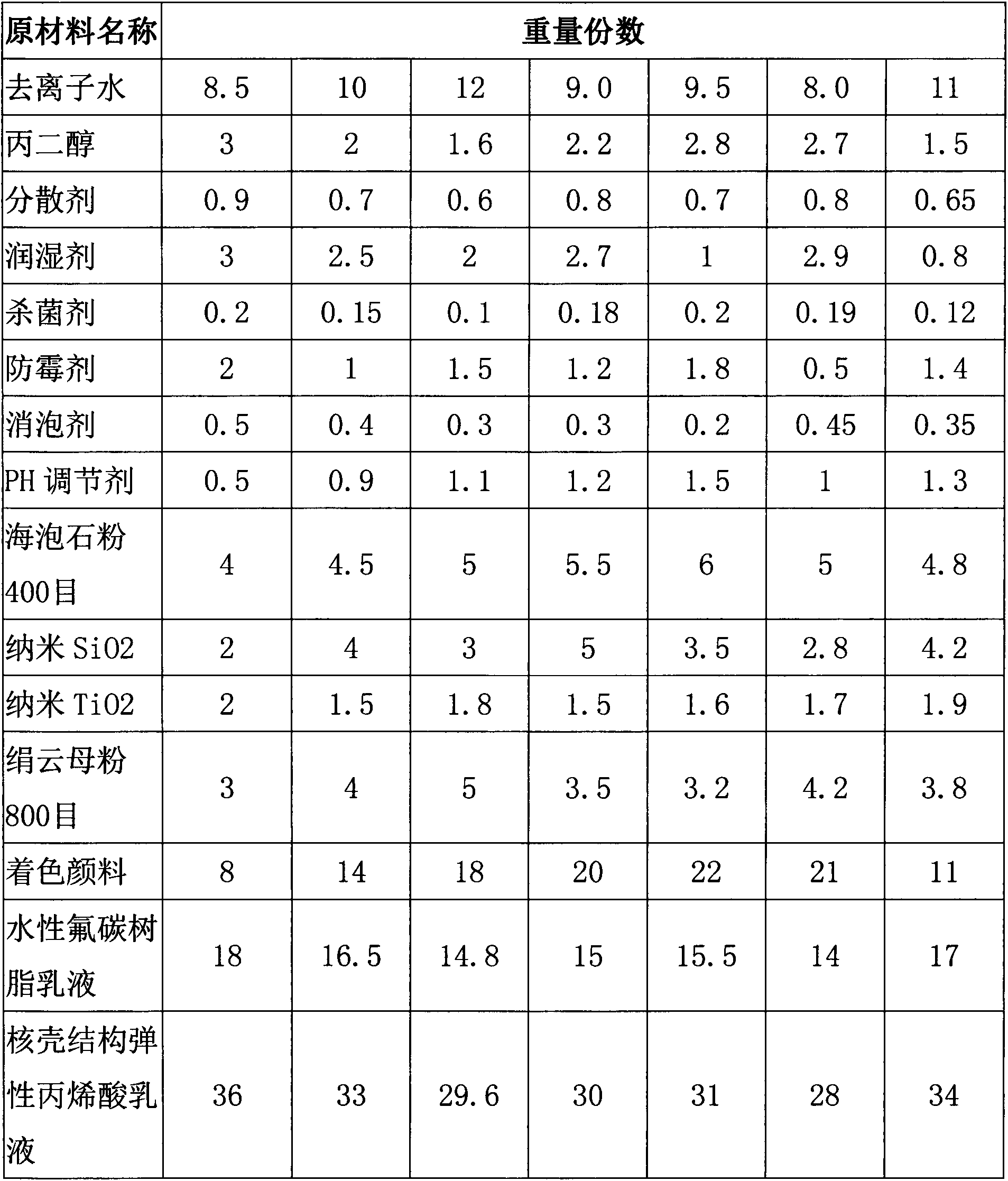

Examples

Embodiment Construction

[0034] Among the present invention, equipment used is 30kw adjustable speed disperser (manufactured by Inoue, Japan), 1000L stainless steel reactor (made in China), 37kw non-adjustable speed disperser (manufactured by Inoue, Japan), 1500L stainless steel reactor (made in China), Electronic automatic measuring equipment (manufactured by Japan Inoue Works), 50kg weighing scale (manufactured by Shanghai Weighing Apparatus Factory).

[0035] The present invention has used the following materials: propylene glycol (U.S. Dow), the dispersant is COADIS123K (French Godess), the wetting agent is EMULSOGEN LCN407 (Clariant Chemicals), the bactericide is CI-15 (Swiss Clariant), the anti-mildew The agent is NIPACIDE IPBC20 (Clariant, Switzerland), the defoamer is BYK025 (Bick Chemical), the pH regulator is 25% potassium hydroxide solution or AMP-95 (Angus Chemical), 400 mesh sepiolite powder (Henan Dongfeng sepiolite), nano-silicon oxide (Zibo Huixin Chemical Co., Ltd.), nano-titanium oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com