Abyssal region seawall sand quilt laying method

A laying method and technology in the deep sea area, applied in dikes, coastline protection, dams, etc., can solve problems such as low construction efficiency, rapid water flow, and difficulty in ensuring quality, and achieve high work efficiency, smooth laying, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

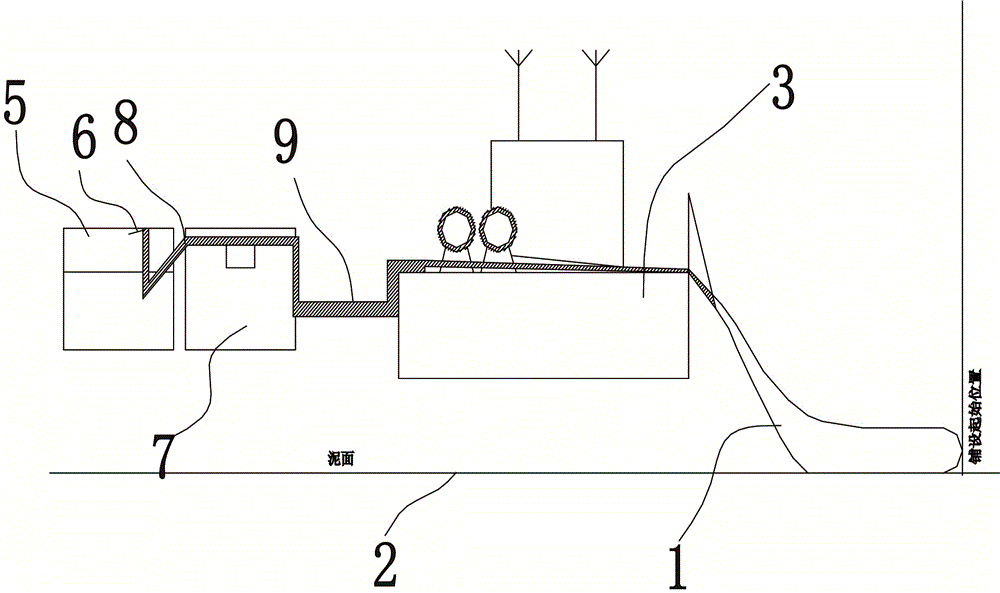

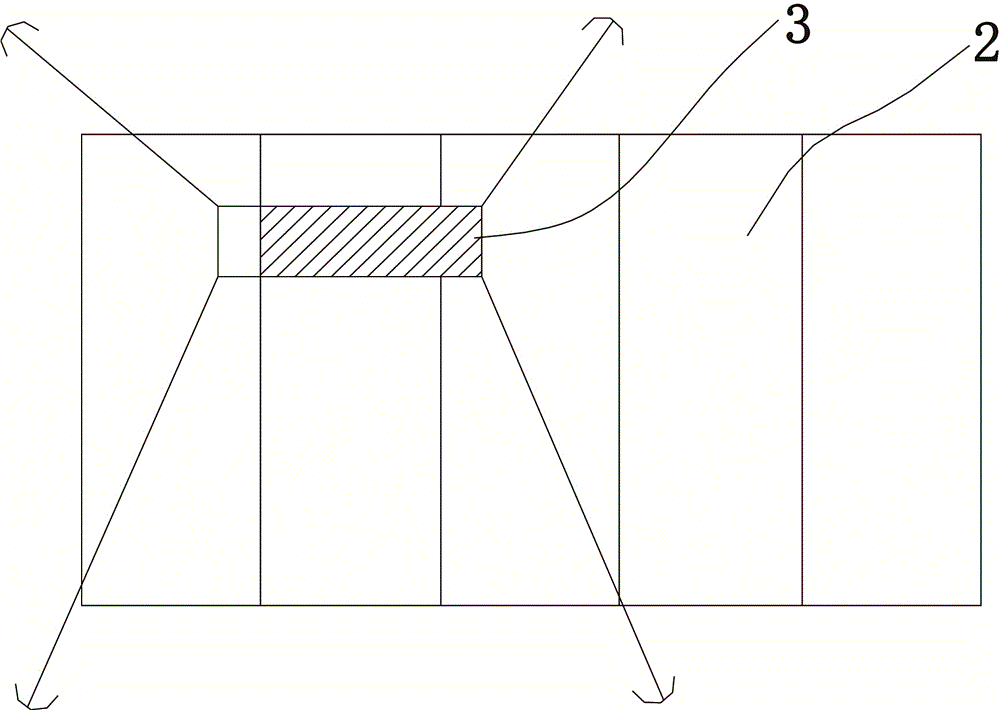

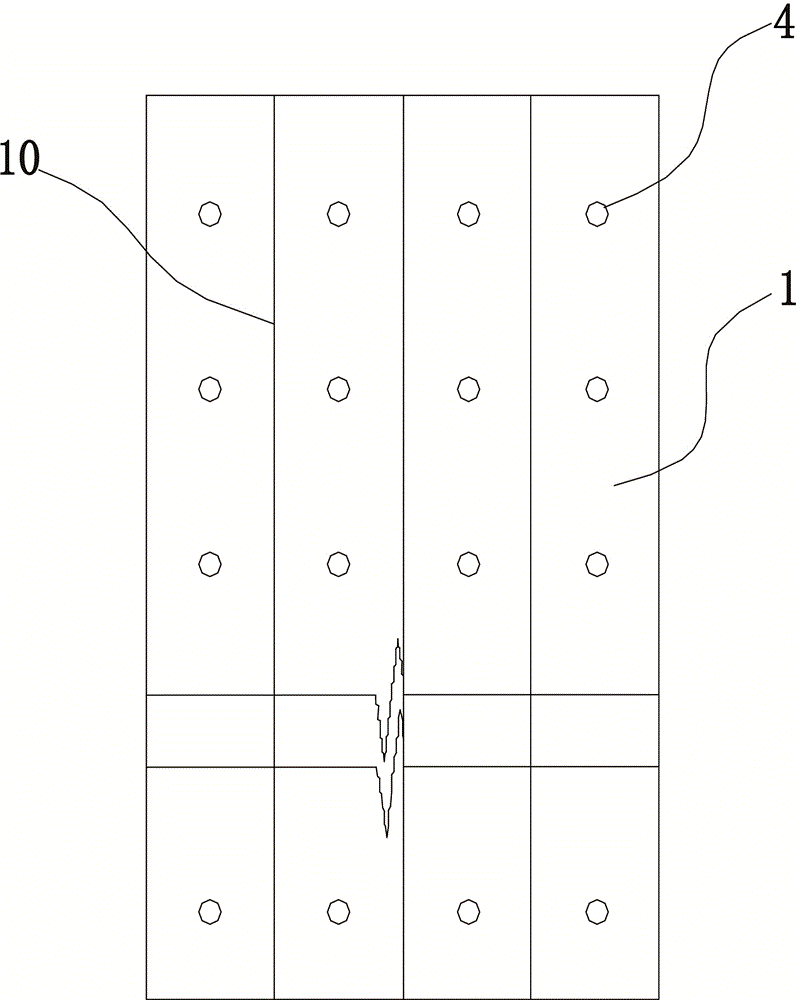

[0018] A method for laying seawall sand in a deep sea area, characterized in that it includes the following steps: a. making a sand-filled bag 1 for loading sand, and the length of the sand-filled bag 1 is longer than the width of the laying area 2; b. The head part of the sand-filled bag 1 is laid flat on the laying ship 3, and except the head part, the rest of the sand-filled bag 1 is wound on the laying ship 2, and During the winding process, the sand-filled bag 1 is straightened to both sides to ensure that the bag is straight during the winding process; c, laying ship positioning: move the laying ship 3 to a predetermined position so that the sand is filled Put the bag head of the bag 1 to one end of the width direction of the laying area 2; d, fill the sand filled bag 1 with filled sand after flushing and slurrying; e, lay it fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com