Hydro-automatic hollow flap gate

A flap gate, hydraulic automatic control technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problem of inflexible opening, non-opening, opening to the maximum if necessary, affecting the ability to pass water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

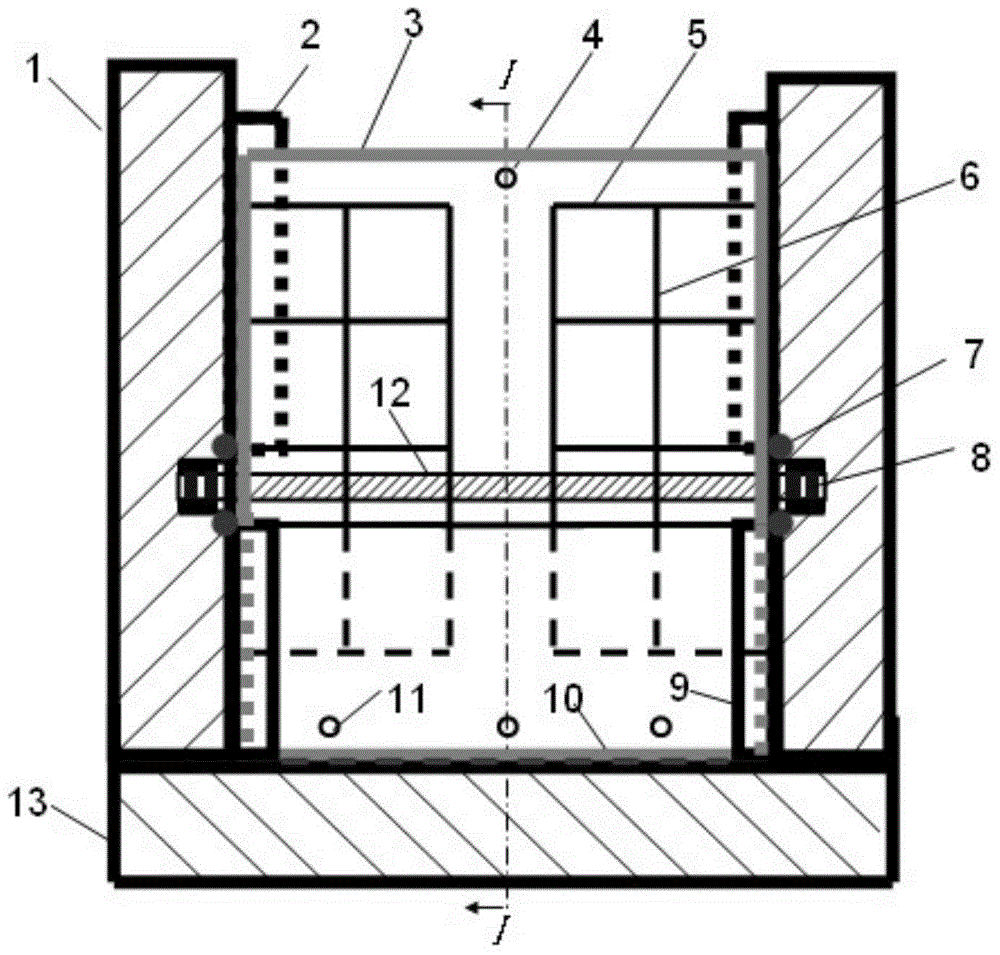

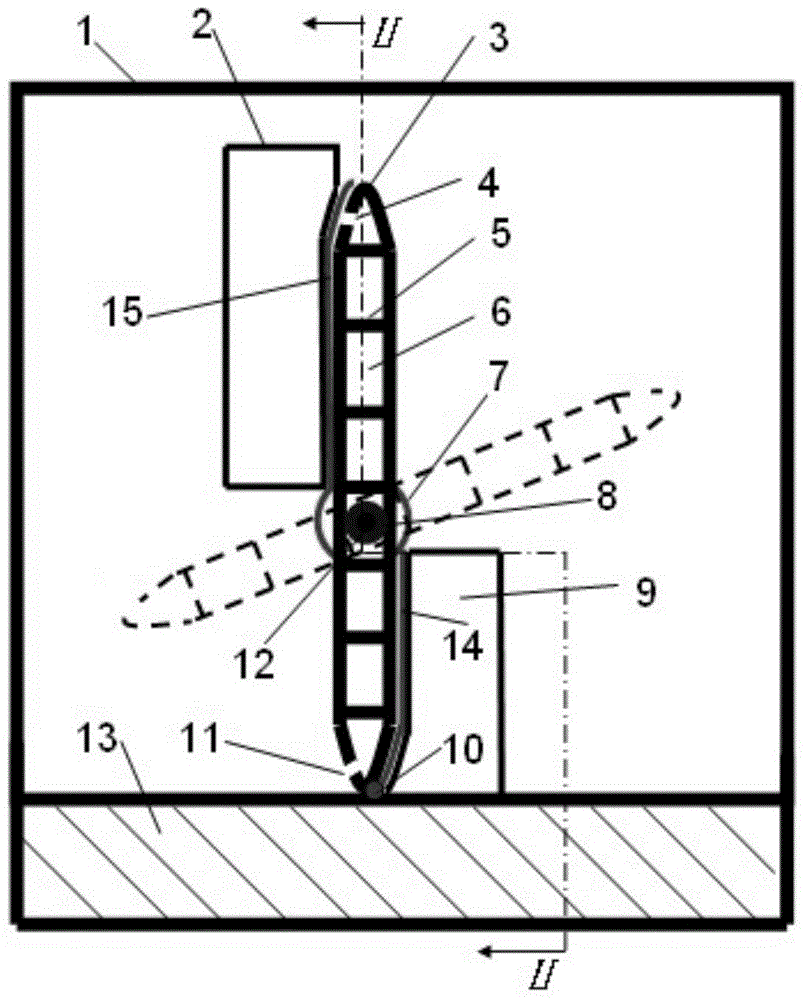

[0012] The pier is of concrete structure, or reinforced concrete structure, or masonry structure, etc., based on the ability to ensure the safety of the pier; the bottom plate of the gate is of reinforced concrete structure, or concrete structure, or masonry structure, etc. The basis is to ensure the safety of the gate pier; the gate piers on both sides and the gate floor are poured on site, and poured into a complete overall structure to increase its stability; the height of the gate pier should be greater than or equal to the height of the gate to ensure safe operation. The gate shaft is made of stainless steel or alloy and is fixed on the gate pier through bearings. The gate shaft is required to have sufficient strength and rigidity to ensure that the gate shaft does not produce any deformation; the hollow gate is made of cast steel or alloy steel and should have Certain rigidity and strength, anti-rust treatment, the hollow gate is provided with longitudinal and transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com