Rotary gate automatically controlled by waterpower and provided with horizontal shaft

A hydraulic automatic control and gate technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of complex hydraulic characteristics of hydraulic automatic flap gates, large force on gate plates and gate piers, unfavorable gate stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

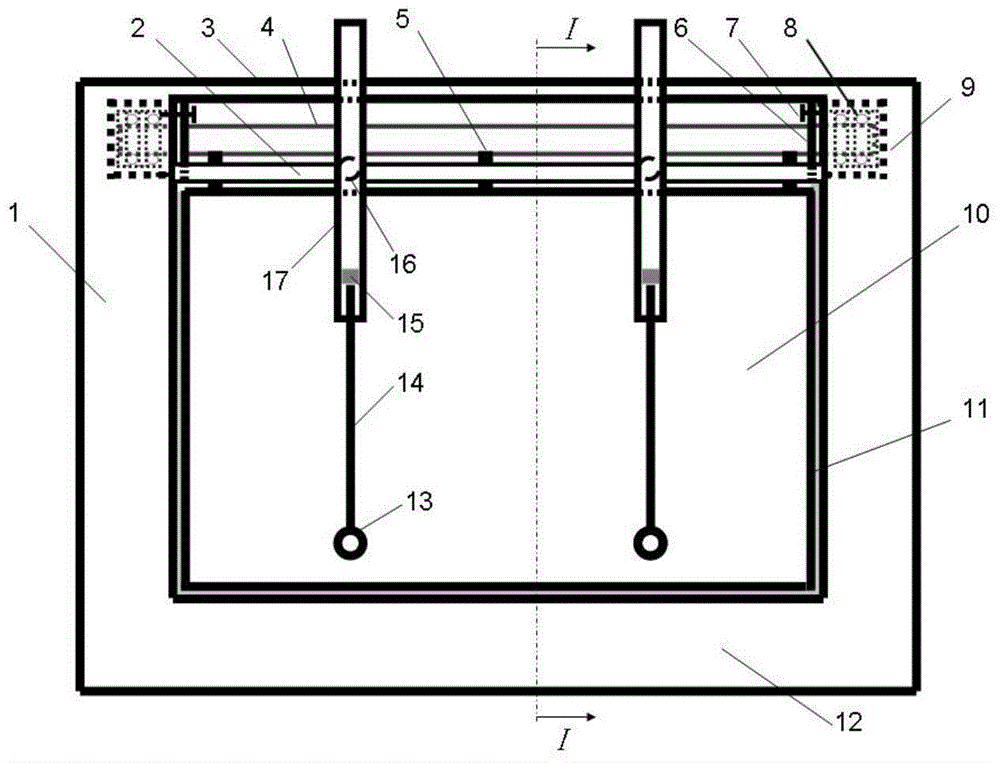

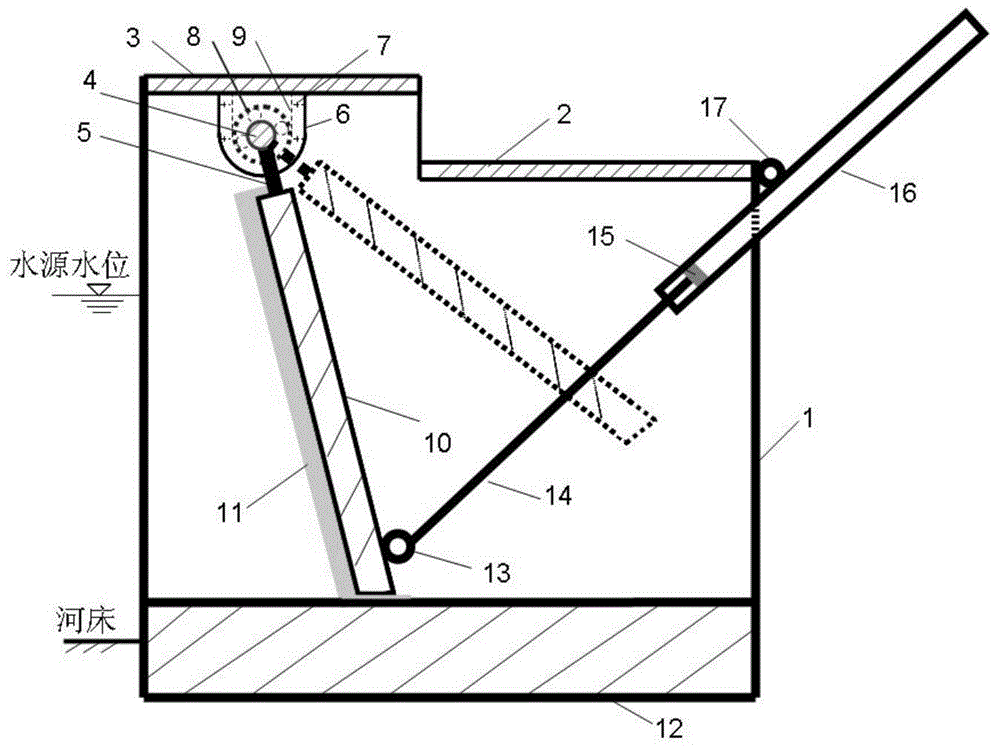

[0015] Such as figure 1 , figure 2 As shown, the device mainly includes a lock chamber, a bearing body, a gate shaft, a rotary gate, a suspension mechanism, a cover bridge, a working bridge, a water stop, and a hydraulic damping device.

[0016] The gate pier is a symmetrically arranged concrete structure, or reinforced concrete structure, or masonry structure, etc. on both sides. Depending on the upstream water depth and force, the height of the gate pier should be greater than the upstream water depth to ensure safety. It is based on operation; the gate bottom plate is reinforced concrete structure, or concrete structure, or mortar masonry structure, etc., depending on the upstream water depth, force, and safety and stability requirements; gate piers and gate bottom plates on both sides are poured on site, and poured into A complete overall structure to increase its stability; the revolving gate is a prefabricated reinforced concrete structure or other materials with certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com