Self-lifting type marine drilling platform lifting device and method

A technology for offshore drilling platforms and lifting devices, which can be used in water conservancy projects, artificial islands, underwater structures, etc., and can solve problems such as slow lifting speed, high requirements for racks and pinions, and high repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

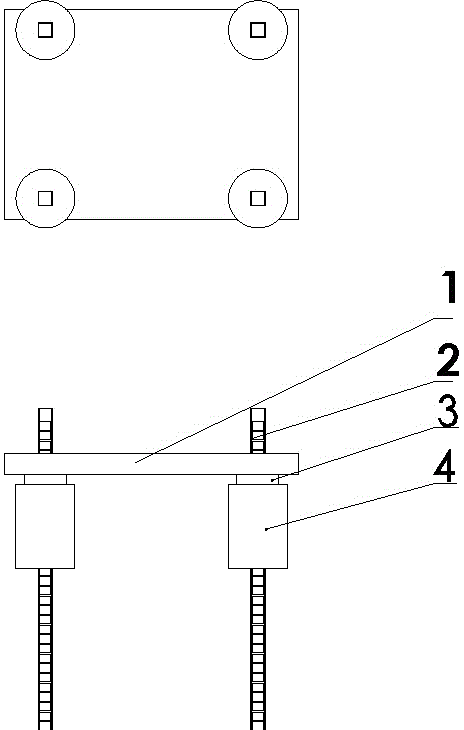

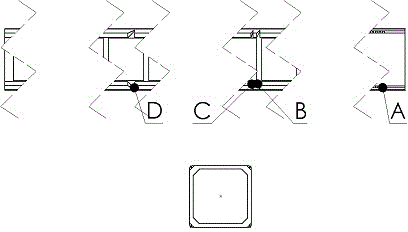

[0048] see figure 1 The lifting device of the self-elevating offshore drilling platform includes a platform (1), legs (2), main floating piles (3), auxiliary floating piles (4), clamping devices between the main floating piles and pile legs, auxiliary floating piles The clamping device between the pile and the pile leg, and the clamping device between the platform and the pile leg are characterized in that there are four pile legs (2), and each pile leg (2) has a main floating pile (3 ) and an auxiliary floating pile (4); the main floating pile (3) and the auxiliary floating pile (4) are slidingly fitted with the leg (2), and can slide up and down along the leg (2), and each main floating pile (3) Four main floating piles and clamping devices between the legs are fixed on the top, and are evenly fixed and installed at the four vertices of the square hole in the middle of the main floating pile (3); each auxiliary floating pile (4) is equipped with four auxiliary The clamping...

Embodiment example 2

[0050] see Figure 1-Figure 9 A new jack-up offshore drilling platform lifting device includes: platform (1), legs (2), main floating pile (3), auxiliary floating pile (4), main floating pile (3) and pile legs (2 ), the clamping device between the auxiliary floating pile (4) and the leg (2), the clamping device between the platform (1) and the leg (2); it is characterized in that there are four legs (2), there is a main floating pile (3) and an auxiliary floating pile (4) on each pile leg, and the main floating pile (3) and the auxiliary floating pile (4) are slidably matched with the pile leg (2), which can Slide up and down along the pile legs (2), each main floating pile (3) is fixed with four clamping devices between the main floating pile (3) and the pile legs (2), evenly fixed and installed on the main floating pile (3) ) at the four vertices of the square hole in the middle, each auxiliary floating pile (4) is equipped with clamping devices between four auxiliary float...

Embodiment example 3

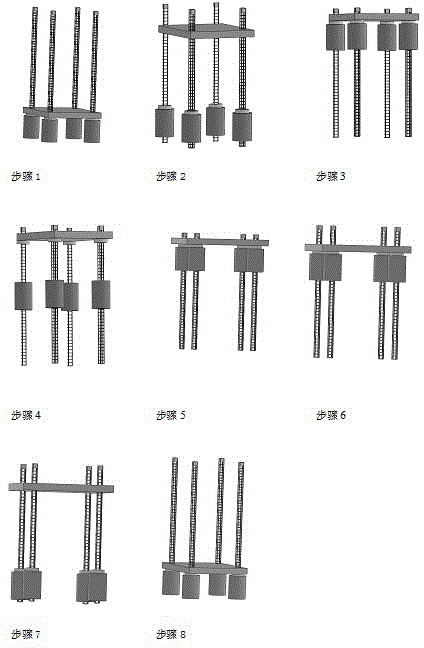

[0069] see figure 2 , the lifting method of the self-elevating offshore drilling platform adopts the above-mentioned device for operation, and the specific operation steps are as follows:

[0070] 1) Step 1: Move the aircraft into place. Platform (1) and main floating pile (3), main floating pile (3) and auxiliary floating pile (4), platform (1) and leg (2), main floating pile (3) and pile leg (2) There is a locking mechanism between them; move to the predetermined sea area;

[0071] 2) Step 2: Platform piling and piling. After arriving at the predetermined sea area, the platform (1) and the main floating pile (3), the locking device of the platform (1) and the leg (2) is loosened, at this time the main floating pile (3) and the auxiliary floating pile (4) The amount of seawater injected makes the overall weight (main floating pile (3) and auxiliary floating pile (4), pile leg (2)) slightly greater than its total buoyancy (in the figure, the device for pumping out seawater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com