Elevating control system of self-elevating drilling platform

A drilling platform, lifting control technology, applied in electrical program control, program control in sequence/logic controller, hydraulic engineering, etc., can solve the problem of poor motor synchronous control effect, single speed mode, can not adapt to jack-up drilling platform Problems such as increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

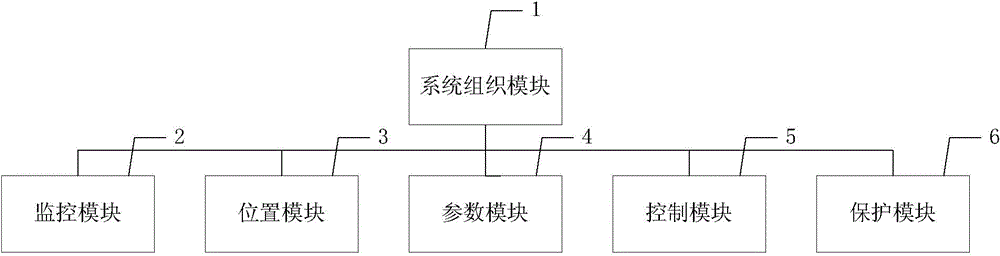

[0035] refer to figure 1 , the lifting control system of the jack-up drilling platform in this embodiment includes: a system organization module 1 , a monitoring module 2 , a position module 3 , a parameter module 4 , a control module 5 and a protection module 6 . The above-mentioned modules can be realized by means of software programs, for example, the CPU of a programmable logic controller can be used to execute corresponding software programs to realize the functions of each module.

[0036] Among them, the system organization module 1 organizes and invokes the monitoring module 2 , the location module 3 , the parameter module 4 , the control module 5 and the protection module 6 . The system organization module 1 is used to periodically execute system program modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com