Hybrid construction machine

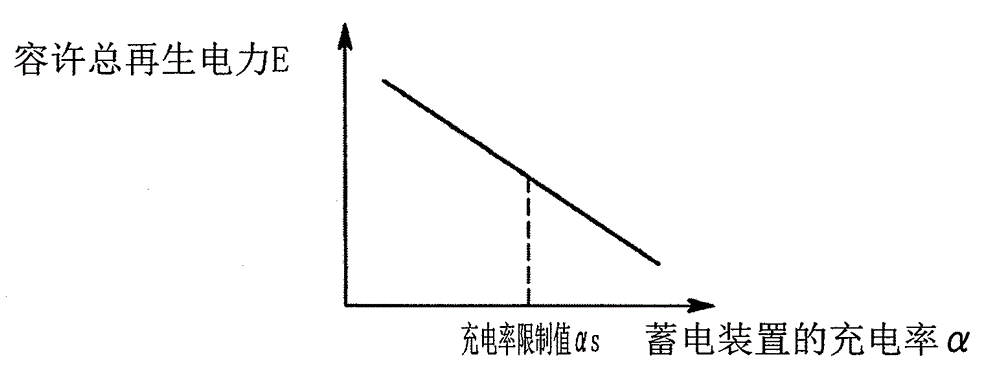

A technology of construction machinery and hybrid power, applied in hybrid vehicles, mechanical equipment, power plants, etc., can solve the problems of increased possibility of overcharging, difficult layout of equipment, energy loss, etc., and achieve the effect of preventing overcharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described with reference to the drawings. This embodiment is suitable for the present invention Figure 7 An example of a hybrid excavator is shown.

[0020] figure 1 The main part of the hybrid excavator of this embodiment is shown. The hybrid except Figure 7 In addition to the shown structural elements, an engine 9 , a generator motor 10 , a hydraulic pump 11 , an electrical storage device 12 , a control unit 13 , and a swing motor 14 are included. figure 1 In , the thick solid line represents the circuit of the power system, the dotted line represents the circuit of the signal system, and the ordinary solid line represents the hydraulic circuit.

[0021] The generator motor 10 and the hydraulic pump 11 are connected in series (or in parallel) to the engine 9 so as to be driven by the engine 9 . The generator motor 10 performs a generator function and a motor function. The hydraulic pump 11 is driven by the engine 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com