Differential pressure reciprocating type well cementation vibrator and method

A vibrator, reciprocating technology, applied in the direction of vibration generating device, earthwork drilling, wellbore/well components, etc., can solve the problems of poor frequency controllability, grouting channel blockage failure, etc., to prolong the service life and ensure construction safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

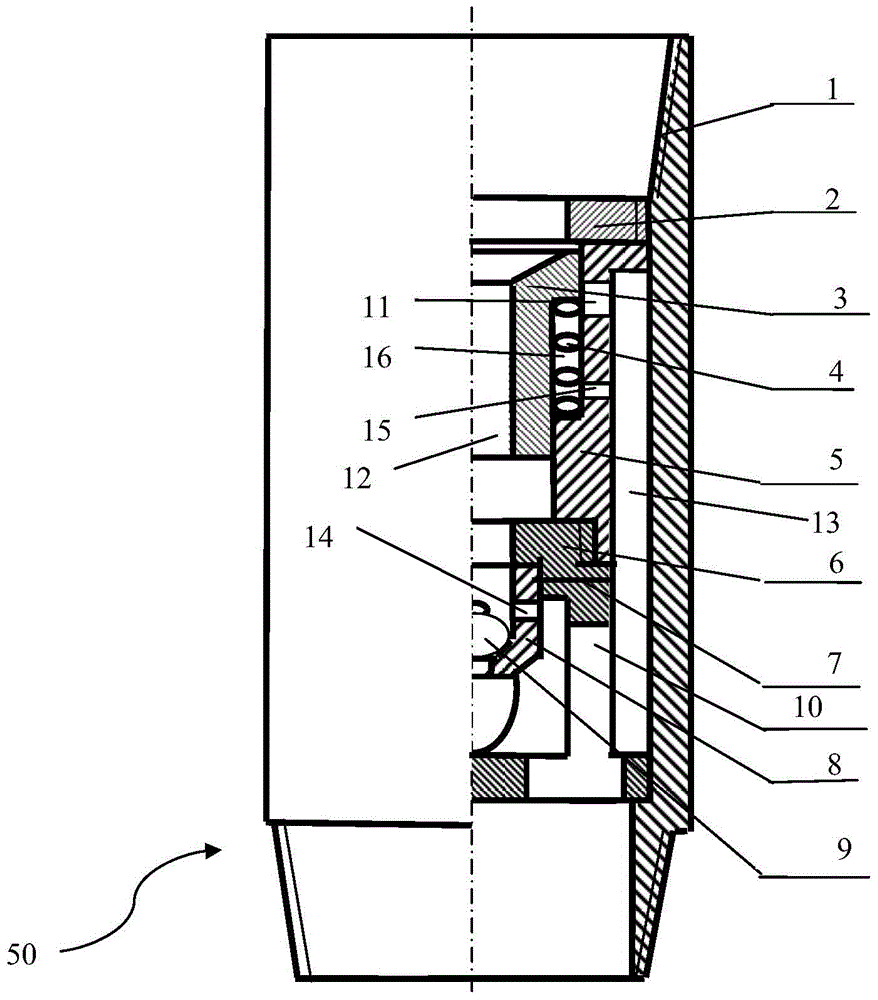

[0028] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0029] figure 1 It shows a differential pressure reciprocating cementing vibrator 50 according to the present invention, which is used to generate downhole vibration waves. The inner cavity of the cementing vibrator 50 is a flow channel for drilling fluid and cement slurry.

[0030] The differential pressure reciprocating cementing vibrator 50 includes a cylindrical body 1 . In one embodiment, the end of the cylindrical body 1 is connected with a sleeve. Both ends of the cylindrical body 1 may be provided with threaded fasteners, which are directly connected to the sleeve through the threaded fasteners.

[0031] The cementing vibrator 50 also includes a cylindrical isolation unit located in the body 1 and connected to it. The isolation unit divides the space in the body 1 into a first cavity 12 on the radially inner side and a second cavity 12 on the radially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com