Process for imparting permanence to a shaped non thermoplastic fibrous material

A fiber material, non-thermoplastic technology, applied in the field of permanently formed fiber materials, can solve impractical problems and achieve the effect of eliminating intermediate steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Will A plain bobbin of 29 para-aramid yarn was used as the starting material for all the examples described below. The yarn consisted of 1000 filaments of 1.5 d / f and had a total density corresponding to 1670 dtex. This material is hereafter referred to as K29. The moisture content of K29 was determined to be 5.9% by weight using ASTM D885-98.

[0097] Using SAURER Elastic twisting machine (elasto-twister) AZB 200 / 240 Set at 500 tpm, a sufficient amount of K29 yarn was twisted and wound directly onto a plastic cylindrical bobbin which was known to be water resistant and showed no appreciable swelling or shrinkage on exposure to water. The 500 tpm twisted K29 yarn is referred to as M3D hereinafter. The actual tpm was confirmed to be 609 tpm using a twist counter Zeigle D311, which is a fairly common deviation from the 500 tpm set point due to the high twist obtained with the manually controlled twister.

[0098] A 50cm M3D sample was allowed to relax freely, al...

Embodiment 2

[0101] Using SAURER Elastic twisting machine (elasto-twister) AZB 200 / 240 Set at 500 tpm, a sufficient amount of K29 yarn was twisted and wound directly onto a plastic cylindrical bobbin which was known to be water resistant and showed no appreciable swelling or shrinkage on exposure to water. The 500 tpm twisted K29 yarn is referred to as M3D hereinafter. The actual tpm was confirmed to be 617 tpm using a twist counter Zeigle D311, which is a fairly common deviation from the 500 tpm set point due to the high twist obtained with the manually controlled twister.

[0102] A sufficient number of M3D bobbins were soaked for 48 hrs in a vessel filled with deionized water, and the resulting fibers were hereinafter referred to as M1-500. The moisture content of M1-500 was determined to be 22.1% by weight using ASTM D885-98.

[0103] A 50cm M1-500 sample was allowed to relax freely to untwist to its natural equilibrium level. Use a twist counter to completely untwist the M1-50...

Embodiment 3

[0106] Using SAURER Elastic twisting machine (elasto-twister) AZB 200 / 240 Set at 500 tpm, a sufficient amount of K29 yarn was twisted and wound directly onto a plastic cylindrical bobbin which was known to be water resistant and showed no appreciable swelling or shrinkage on exposure to water. The 500 tpm twisted K29 yarn is referred to as M3D hereinafter. The actual tpm was confirmed to be 611 tpm using a twist counter Zeigle D311, which is a fairly common deviation from the 500 tpm set point due to the high twist obtained with the manually controlled twister.

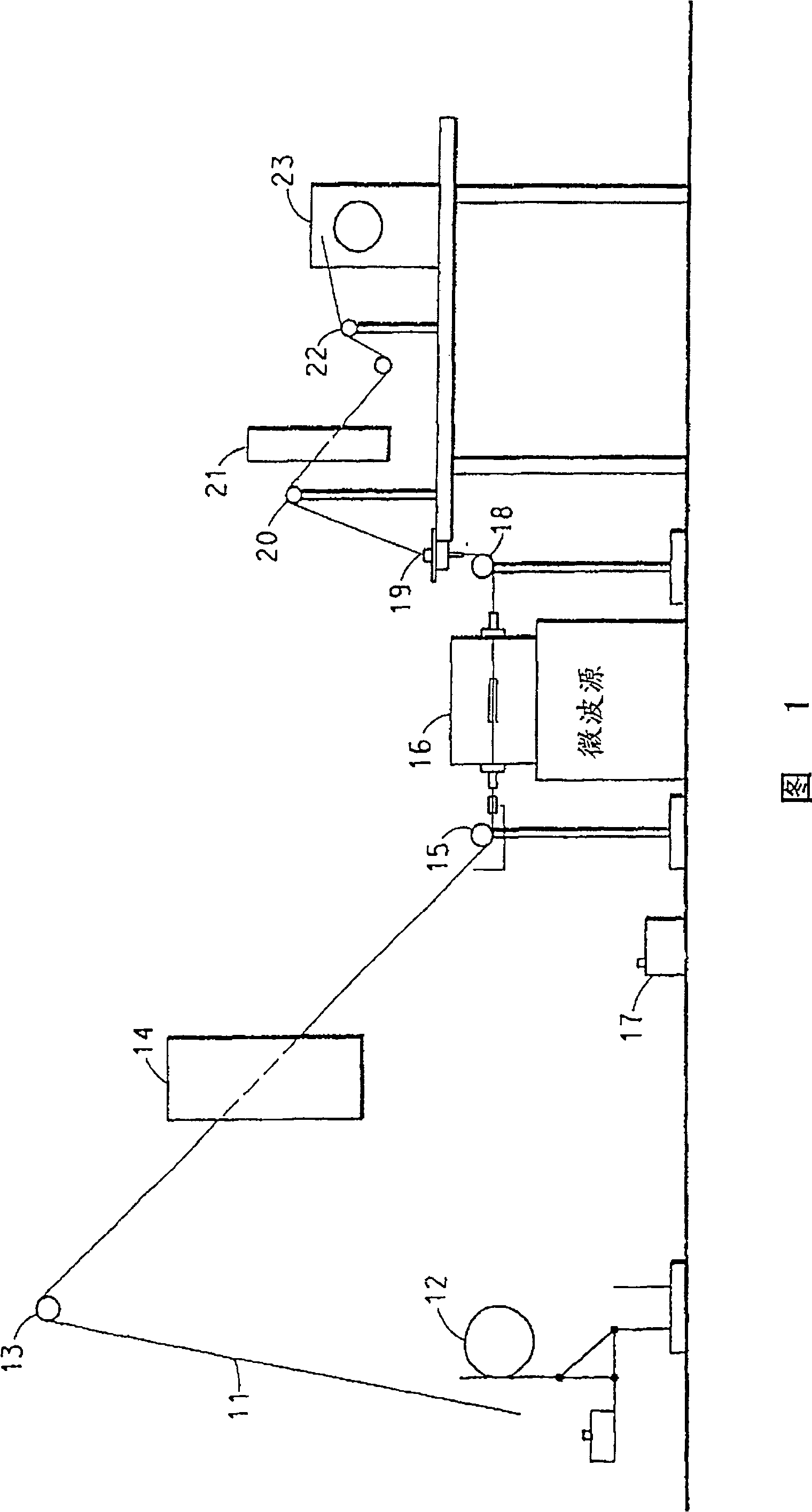

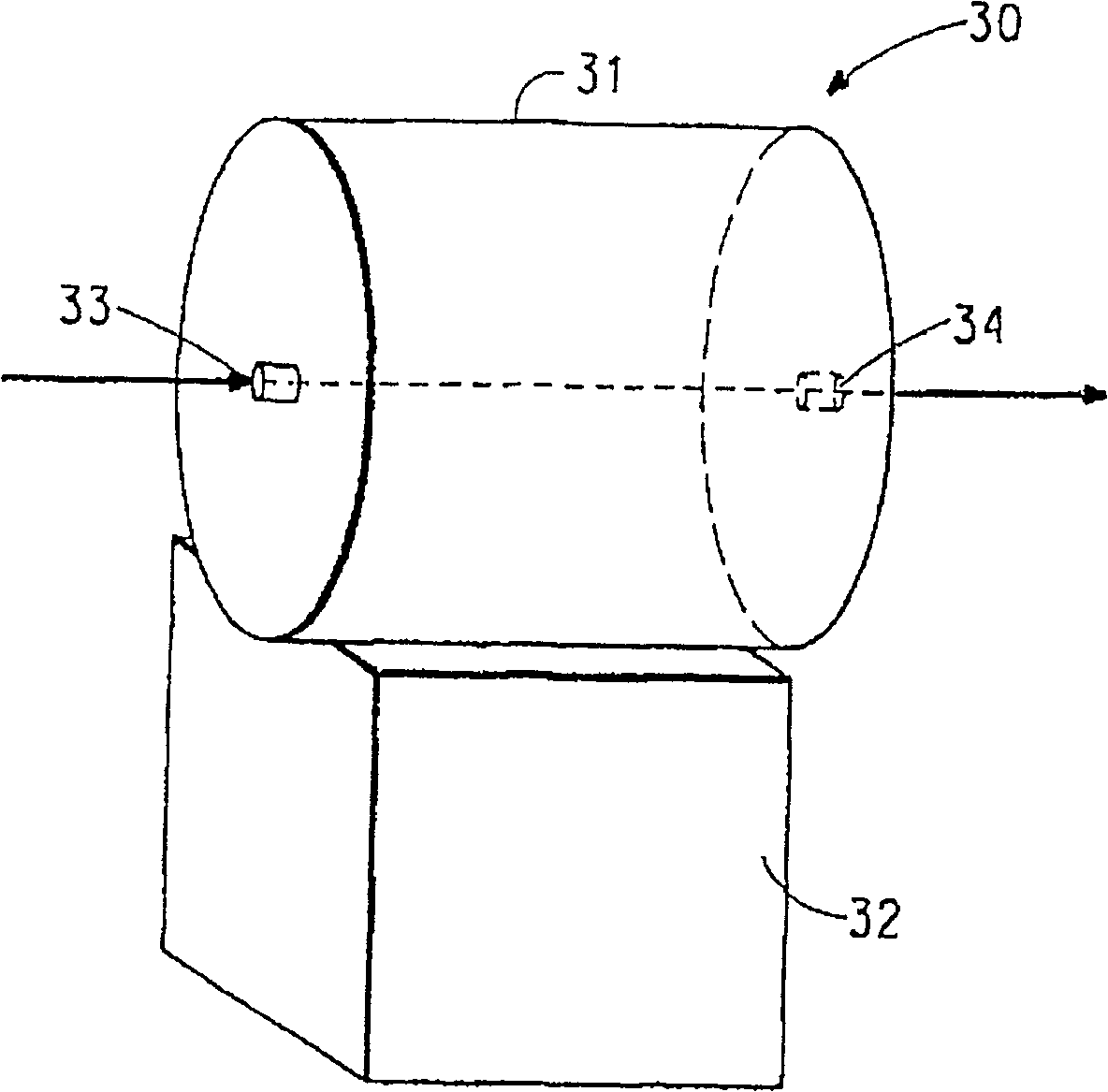

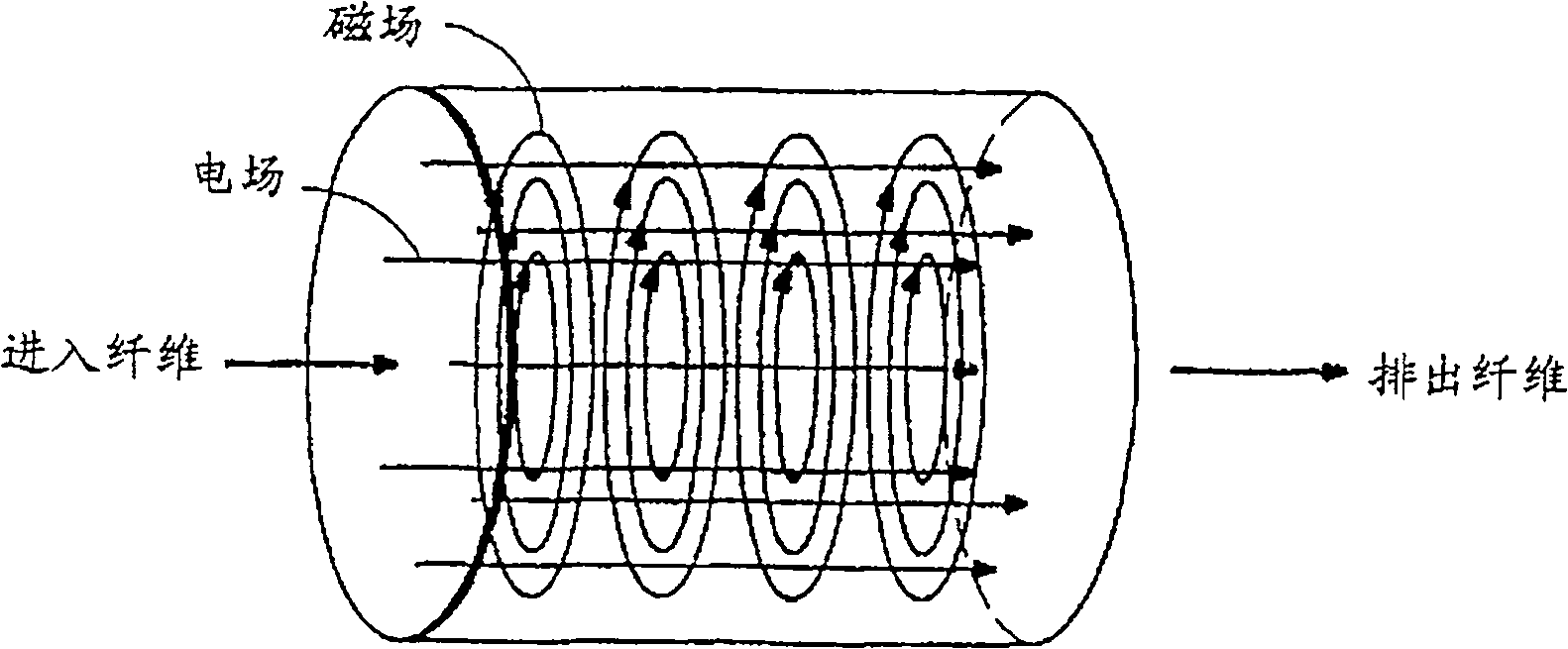

[0107] Immerse a sufficient number of M3D cartridges in a container of deionized water for 48hr. Take out the bobbin from the container and feed it into the off-line processing device in Fig. 1 at 6m / min. The corresponding residence time in the cylinder TM010 resonant cavity is 3 seconds. figure 2 The resonant cylindrical cavity is depicted and its dimensions are also provided. The temperature of the fiber en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com