Completion tester and its system

A tester and cavity technology, which is applied in the field of well completion testers and their systems, can solve the problems of complicated testing process, inconvenience to use, inconvenient to use, etc., and achieve the effect of simple testing process and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

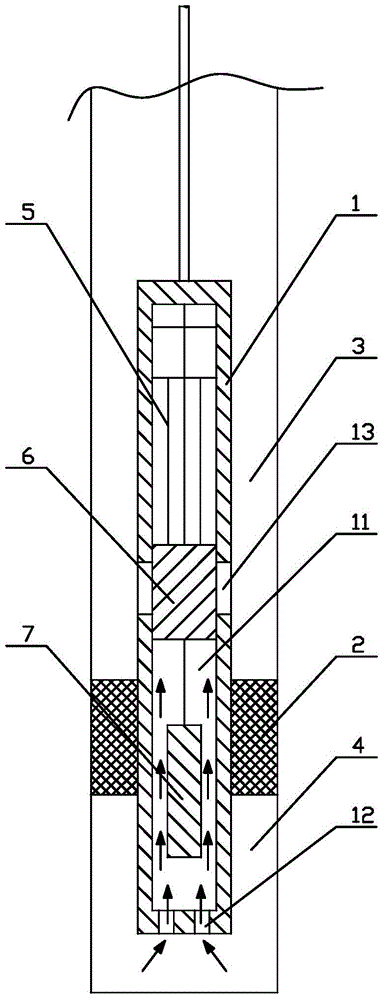

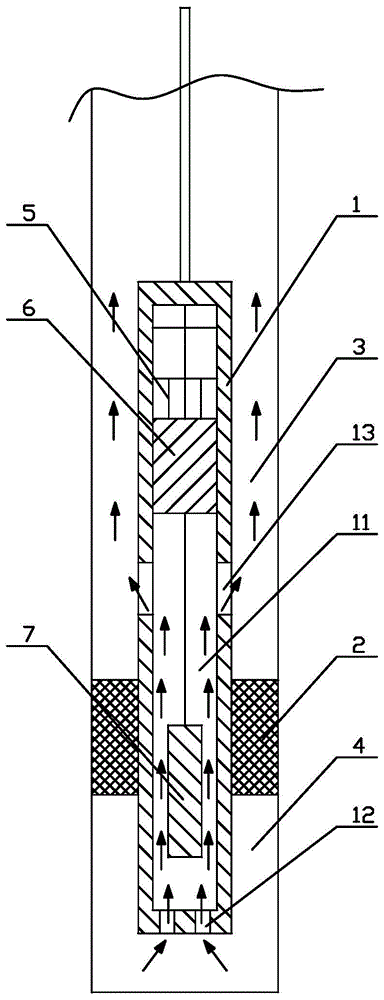

[0074] Such as figure 1 with figure 2 As shown, the completion tester provided in this embodiment includes: a first shell 1 with a flow channel cavity 11 formed inside; a packing device 2 for setting outside the first shell 1, And the isolation device 2 is used to divide the downhole into the upper cavity 3 and the lower cavity 4; the driving device 5 arranged in the flow channel cavity 11 and the sliding rod 6 connected with the driving device 5, the driving device 5 drives the sliding rod 6 moves in the axial direction; the test device 7 arranged in the first housing 1, the test device 7 is located below the slide bar 6; formed in the lower part of the first housing 1 and connected with the flow channel cavity 11 and the lower cavity 4 The liquid inlet 12 connected with each other, and the liquid outlet 13 formed on the first shell 1 above the isolation device 2 and connected with the flow channel cavity 11 and the upper cavity 3; wherein, the slide bar 6 can Driven by th...

Embodiment 2

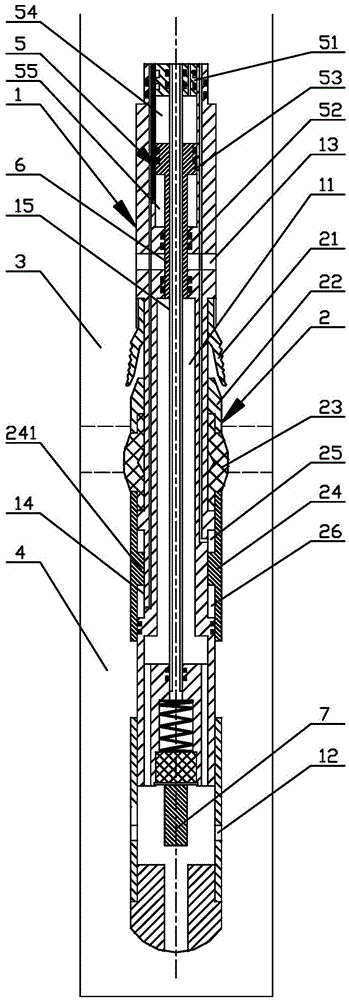

[0083] Such as image 3 As shown, the completion tester provided in this embodiment includes: a first shell 1 with a flow channel cavity 11 formed inside; a packing device 2 for setting outside the first shell 1, And the isolation device 2 is used to divide the downhole into an upper cavity 3 and a lower cavity 4 (the dotted line in the figure indicates that the isolation device 2 is in an open state and is attached to the well wall); it is installed in the flow channel cavity The driving device 5 in the body 11 and the sliding rod 6 connected with the driving device 5, the driving device 5 drives the sliding rod 6 to move axially; the testing device 7 arranged in the first housing 1, the testing device 7 is located on the sliding rod 6 The lower part of the first casing 1 is formed with a liquid inlet 12 that communicates with the flow channel cavity 11 and the lower cavity 4, and the first casing 1 is located above the isolation device 2 and is formed with a flow channel cav...

Embodiment 3

[0111] Such as Figure 4 As shown, a well completion testing system is provided in this embodiment, including an auxiliary controller and the completion tester described in Embodiment 2 above; the auxiliary controller includes a second housing 8 with a mounting cavity, and along The control circuit device 9 and the hydraulic oil tank 91 are sequentially arranged in the second housing 8 axially downward; wherein, the lower end of the second housing 8 is connected to the upper end of the first housing 1, and the control circuit device 9 is connected to the testing device 7 The hydraulic oil tank 91 is connected with the first cavity 54 , the second cavity 55 , the third cavity 25 and the fourth cavity 26 respectively.

[0112] The specific working process and beneficial effects of the well completion tester in the well completion test system provided in this embodiment have been fully described in Embodiment 2, and will not be described again.

[0113] The control circuit devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com