Drainage device

A technology of a liquid discharge device and a liquid discharge hole, which is applied to parts of pumping devices for elastic fluids, liquid variable displacement machines, liquid fuel engines, etc. Complicated problems, to achieve the effect of smooth movement, wide applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

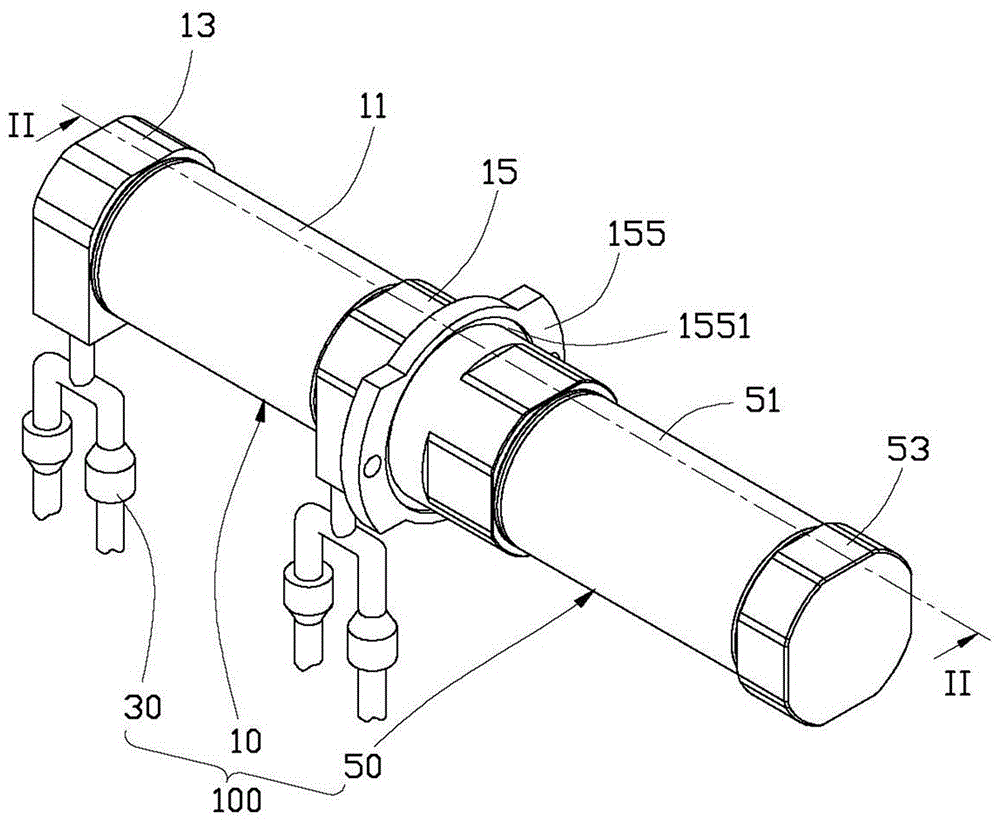

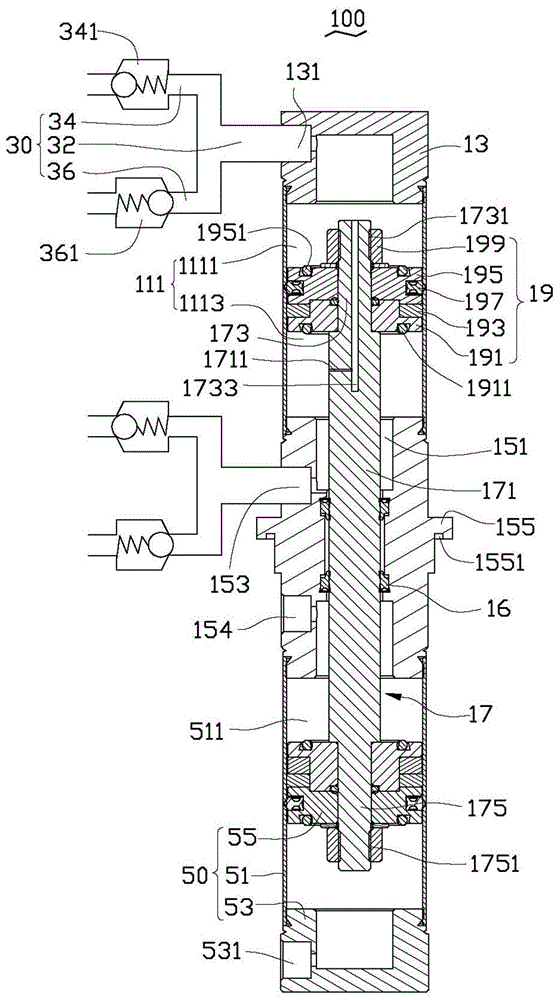

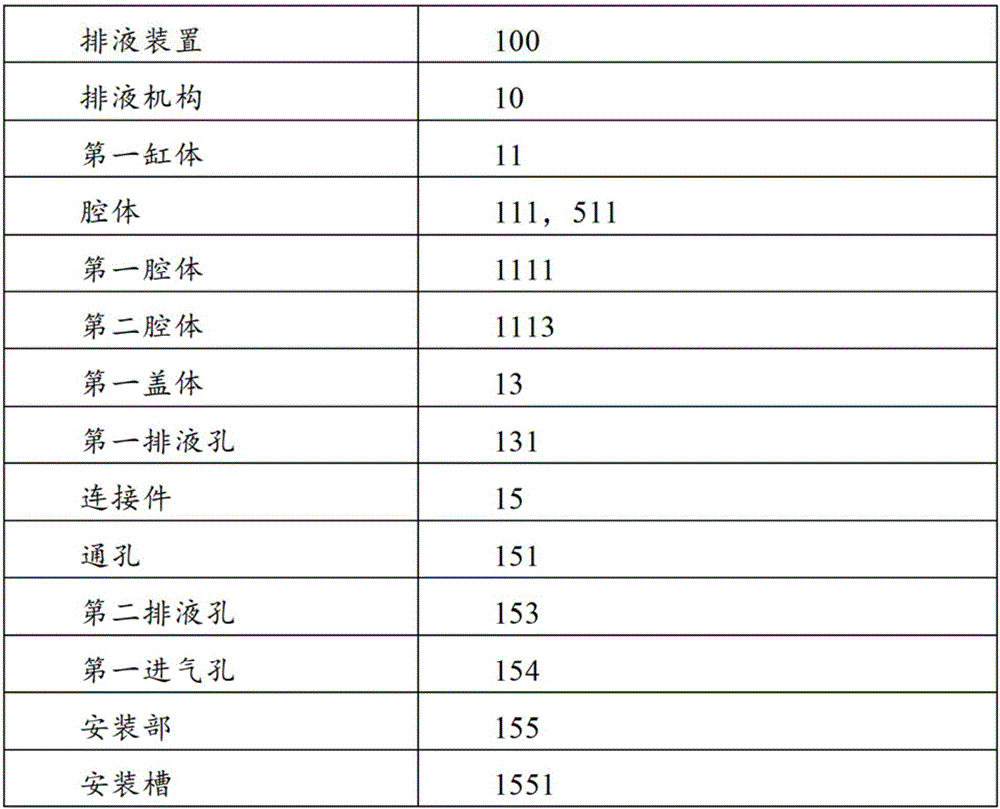

[0012] see figure 1 , the liquid discharge device 100 provided by the embodiment of the present invention is used to discharge liquid (such as water, solution, oil, etc.) from a container (not shown in the figure), and is especially suitable for liquid discharge in a vacuum environment. The liquid discharge device 100 includes a liquid discharge mechanism 10 , a liquid discharge pipe 30 connected to the liquid discharge mechanism 10 , and a driving mechanism 50 . The driving mechanism 50 can drive the liquid discharge mechanism 10 to discharge the liquid from the container through the liquid discharge pipe 30 .

[0013] Please also refer to figure 2 , The liquid discharge mechanism 10 is designed in the form of a cylinder, which includes a first cylinder body 11 , a first cover body 13 , a connecting piece 15 , a sealing piece 16 , a piston rod 17 and a first piston assembly 19 . The first cover 13 and the connecting piece 15 are arranged on the opposite ends of the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com