High-strength electromotor rotary shaft with vent holes

A technology for motor shafts and ventilation holes, applied to shafts, shafts, bearings, mechanical equipment, etc., can solve problems such as prone to failure, and achieve the effects of prolonging service life, reasonable structure, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

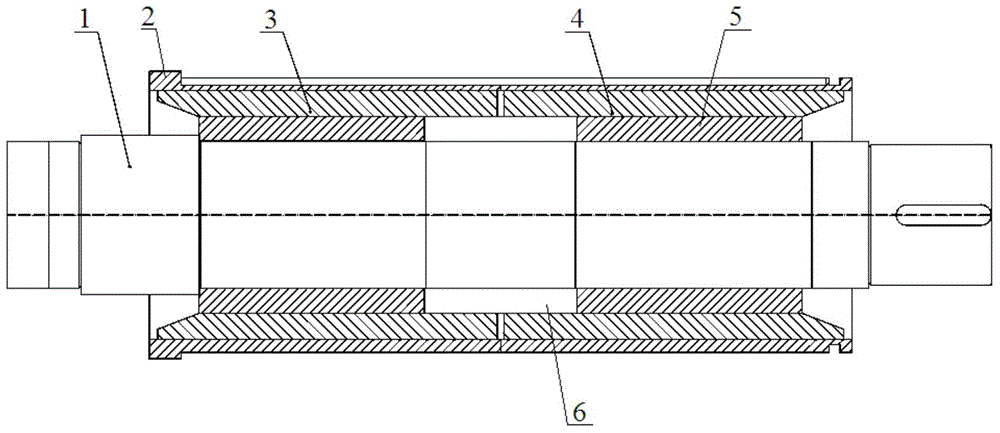

[0010] see figure 1 , a high-strength motor shaft with ventilation holes, including a motor shaft 1, a hollow shaft 2 and front and rear cylinders 3, 4, the motor shaft 1 passes through the hollow shaft 2, the front and rear cylinders 3, 4 are respectively set inside the hollow shaft 2, and six key grooves are respectively arranged around the inner walls of the front and rear cylinders 3 and 4, and six support ribs 5 are respectively embedded in the six key grooves, and the six support ribs 5 form a ring shape It is set on the outside of the motor shaft 1, and the six braces 5 are evenly distributed, and the gap between two adjacent braces forms a ventilation hole 6.

[0011] In the present invention, the outer circular surfaces of the front and rear cylindrical bodies 3 and 4 are respectively full circle structures, and are in surface contact with the inner wall of the hollow shaft 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com