Double-intermediate shaft transmission assembly matched with parallel hydrodynamic retarder

A technology of hydraulic retarder and double intermediate shafts, which is applied to components with teeth, transmission parts, gear transmissions, etc., to improve the smoothness of shifting, increase the axial space, and improve the smoothness of meshing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

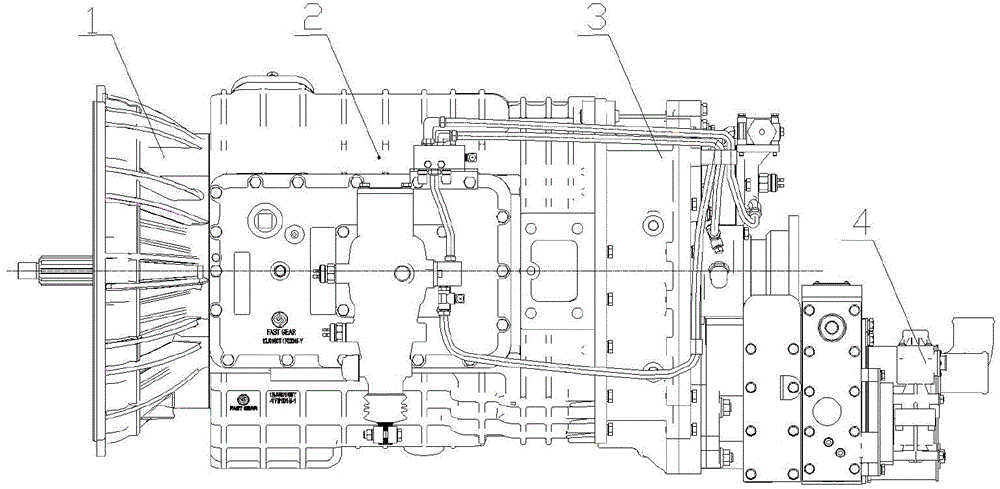

[0034] Such as figure 1 As shown, it is a structural diagram of a double countershaft transmission matched with a parallel hydraulic retarder 4. A double countershaft transmission generally includes a clutch assembly 1, a housing assembly 2, and a rear cover assembly arranged sequentially along the power transmission direction. 3. The improvement of the present invention lies in that the rear cover assembly 3, the clutch assembly 1 and the housing assembly 2 remain in their original state.

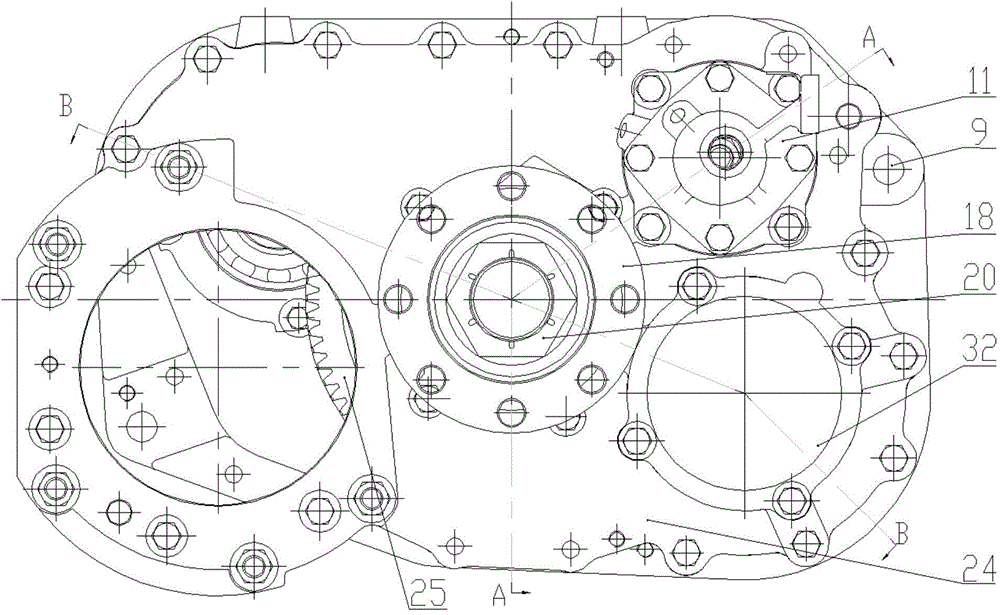

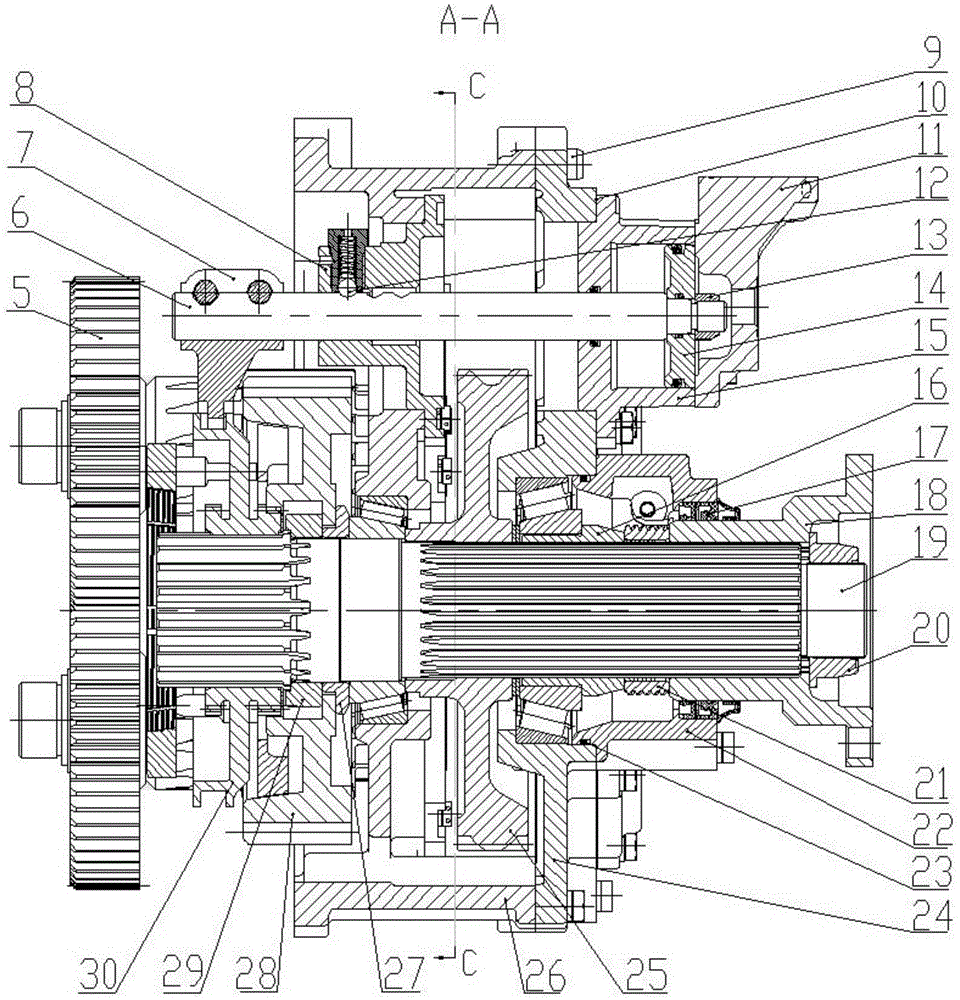

[0035] Such as figure 2 and image 3 As shown in the figure, an output shaft 19 is installed at the center of the back cover 24, and the output shaft 19 is fixed with a retarder driven gear 25 through an internal spline, and a window is opened on the back cover 24 for parallel hydraulic retarding The installation and positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com