High-temperature-resistant and refrigerant-resistant air conditioner hose

A refrigerant, high and low temperature resistant technology, applied in the field of rubber tubes, can solve the problems of poor bonding performance, poor air tightness, and poor processing performance of the shielding layer, and achieve good high temperature resistance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

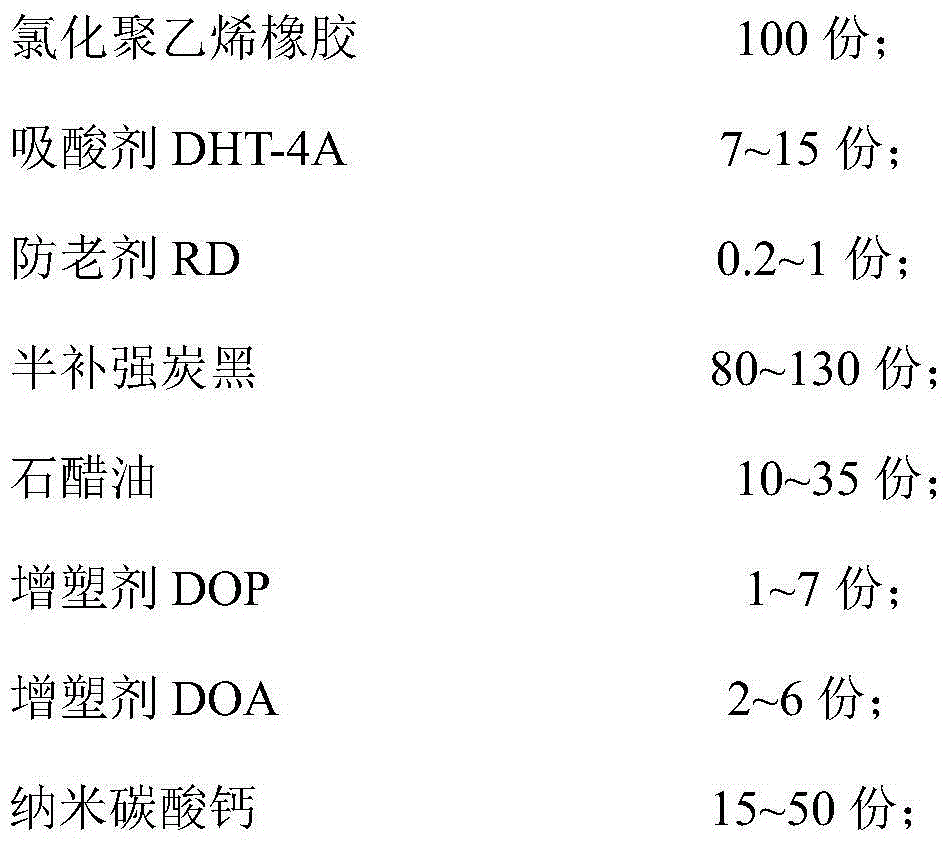

[0024] The high-temperature and refrigerant-resistant air-conditioning hose includes an inner rubber layer, a shielding layer, a middle rubber layer, a braided layer and an outer rubber layer arranged from the inside out. The components and mass parts of the inner rubber layer and the middle rubber layer are:

[0025]

[0026] The middle rubber layer and the inner rubber layer made by the above formula are made into a film for testing and testing. The experimental data are as follows:

[0027]

[0028]

[0029] The performance test of the air-conditioning hose made of the above formula is carried out, and the experimental data are as follows:

[0030]

Embodiment 2

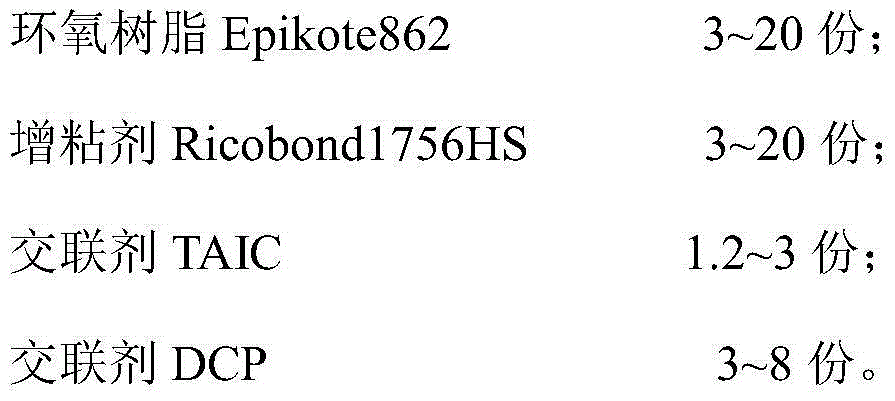

[0032] The high-temperature and refrigerant-resistant air-conditioning hose includes an inner rubber layer, a shielding layer, a middle rubber layer, a braided layer and an outer rubber layer arranged from the inside out. The components and mass parts of the inner rubber layer and the middle rubber layer are:

[0033]

[0034]

[0035] The middle rubber layer and the inner rubber layer made by the above formula are made into a film for testing and testing. The experimental data are as follows:

[0036]

[0037] The performance test of the air-conditioning hose made of the above formula is carried out, and the experimental data are as follows:

[0038]

Embodiment 3

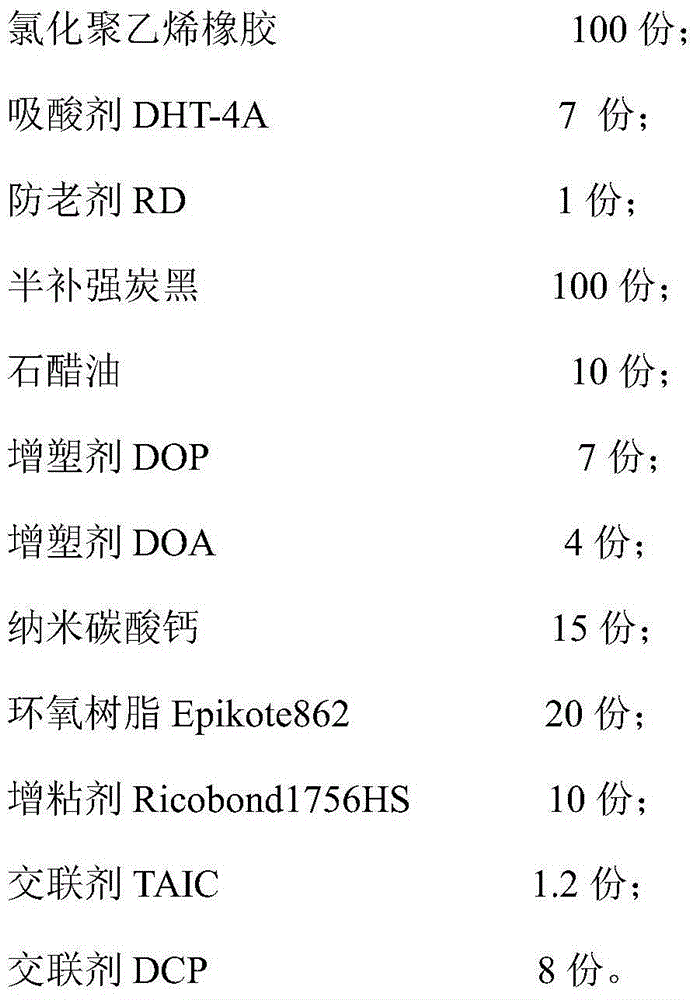

[0040] The high-temperature and refrigerant-resistant air-conditioning hose includes an inner rubber layer, a shielding layer, a middle rubber layer, a braided layer and an outer rubber layer arranged from the inside out. The components and mass parts of the inner rubber layer and the middle rubber layer are:

[0041]

[0042] The middle rubber layer and the inner rubber layer made by the above formula are made into a film for testing and testing. The experimental data are as follows:

[0043]

[0044] The performance test of the air-conditioning hose made of the above formula is carried out, and the experimental data are as follows:

[0045]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap