Displayer base and welding jig device thereof

A technology for welding fixtures and displays, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unstable center of gravity, high production cost, and complicated process of the display, and achieve low production cost, beautiful appearance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

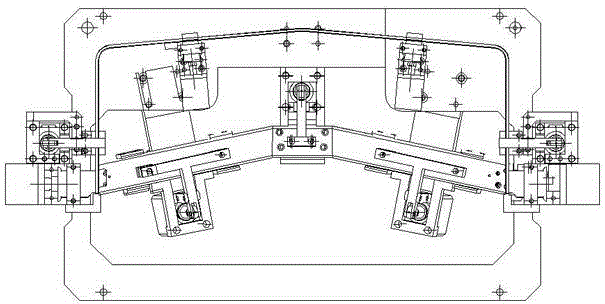

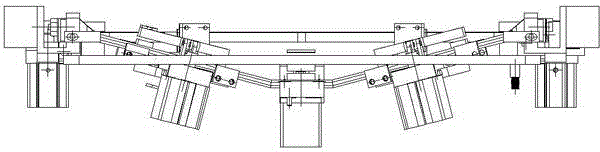

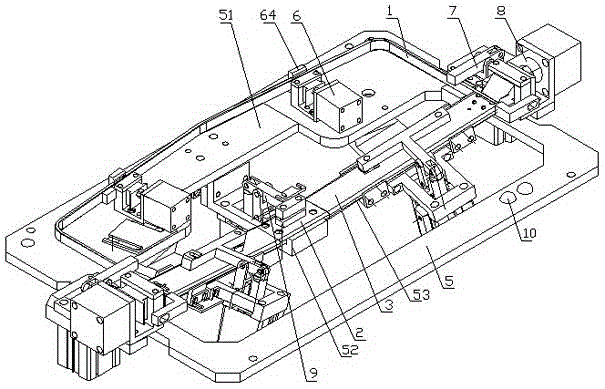

[0025] Such as Figure 1~8 As shown, a display base includes a horizontal U-shaped chassis 1, a connecting seat 2 arranged above the center of the opening of the U-shaped chassis 1, and two U-shaped bottoms symmetrically arranged on both sides of the connecting seat 2. A splicing plate 3 with an inclined opening in the frame 1, one end of the splicing plate 3 is connected to the inner side of one limb of the U-shaped chassis 1, and the other end is connected to one side of the connecting seat 2.

[0026] In this embodiment, the connecting seat 2 is arranged between the inner arc of the U-shaped chassis 1 and the connecting line between the ends of the two limbs of the U-shaped chassis 1, and several connecting seats are symmetrically arranged on the connecting seat 2. The connecting hole 4 of the display support arm; the U-shaped chassis 1, the connecting seat 2 and the splicing plate 3 are all made of stainless steel.

[0027] In this embodiment, a welding jig device for a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com