Recycling steam condensate water, organic waste gas combustion heat and exhaust waste heat method

A technology of organic waste gas and steam condensation, applied in the combustion method, combustion type, household heating and other directions, can solve the problems of environmental protection, energy and water waste, save steam costs, save heating costs, reduce sewage treatment costs and The effect of cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

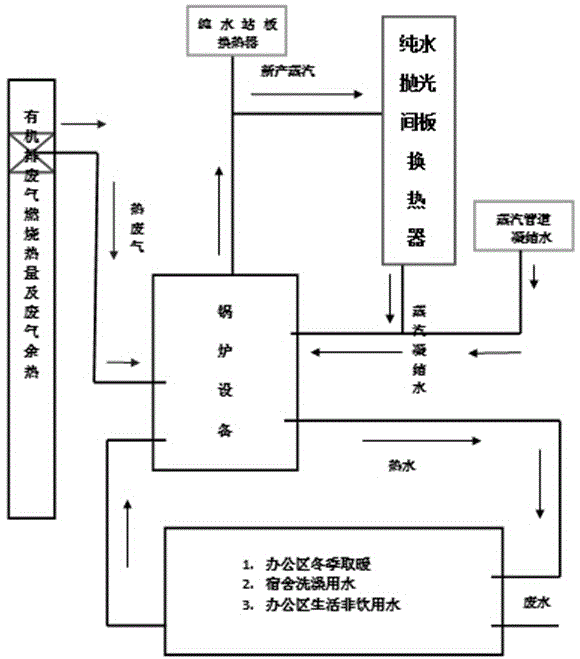

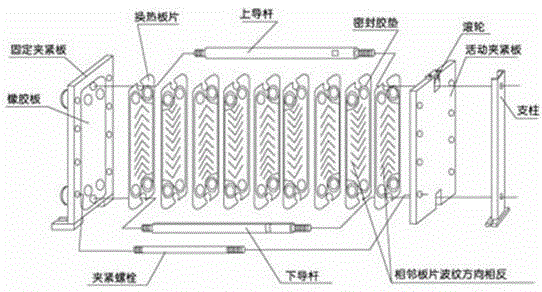

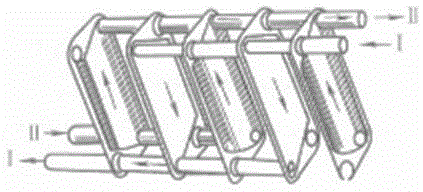

[0037] The hot exhaust gas generated by the company's organic waste gas combustion furnace flows into the boiler equipment through the heat-resistant insulation pipe, and the condensed water in the steam pipeline flows into the boiler equipment through the insulation pipe, and the hot exhaust gas and steam condensate in the boiler equipment are heated. After reaching 40-50°C, the boiler equipment heats the condensed water for 10-15 minutes to generate steam at about 120°C, and the generated steam is transported to the factory plate heat exchanger through the thermal insulation steam pipeline, and then sent to the factory for pure water heating as required; Insulation pipes provide heating sources for office area heating in winter, hot water for washing in dormitories and washing vegetables in canteens, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com