A modular water-cooled cabinet and its noise redundancy control method

A water-cooled, modular technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high noise, poor maintainability, weak environmental adaptability, etc., to reduce power loss, high reliability, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

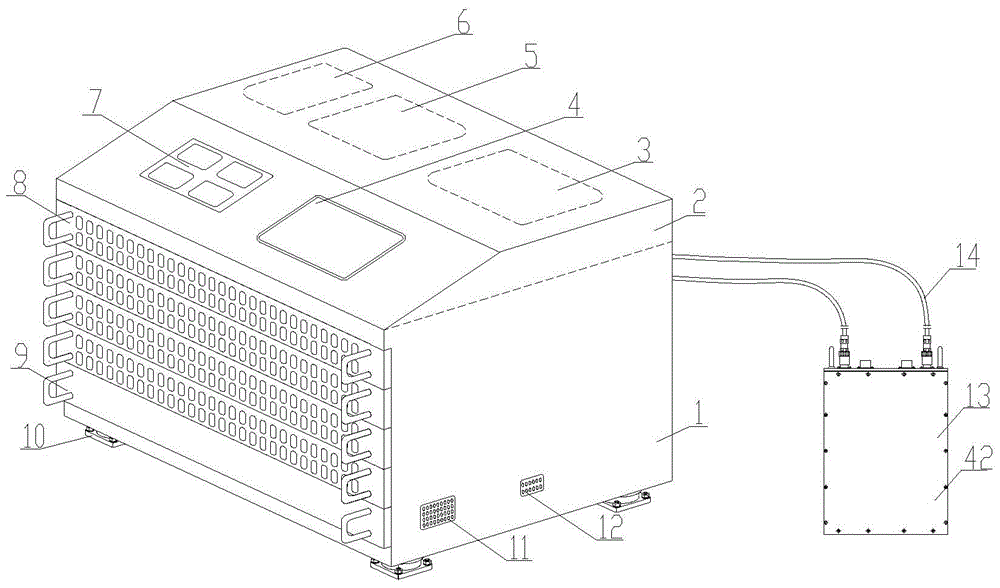

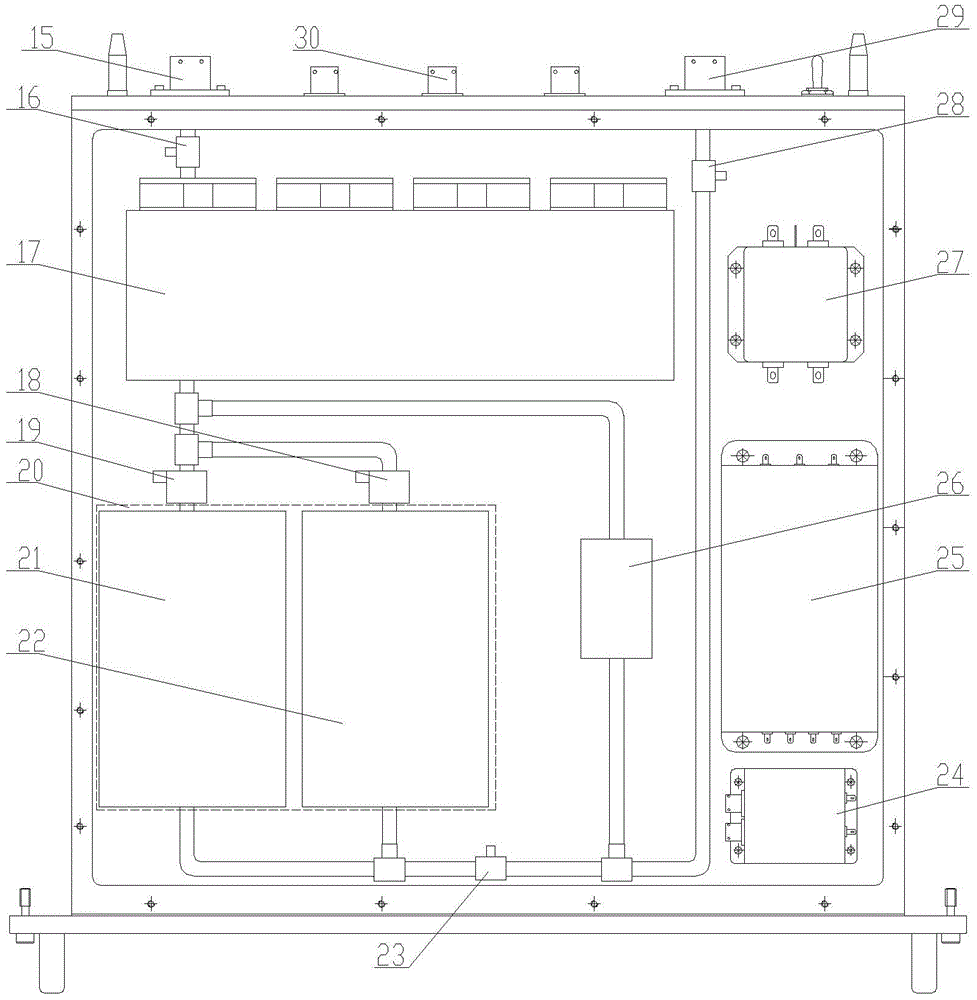

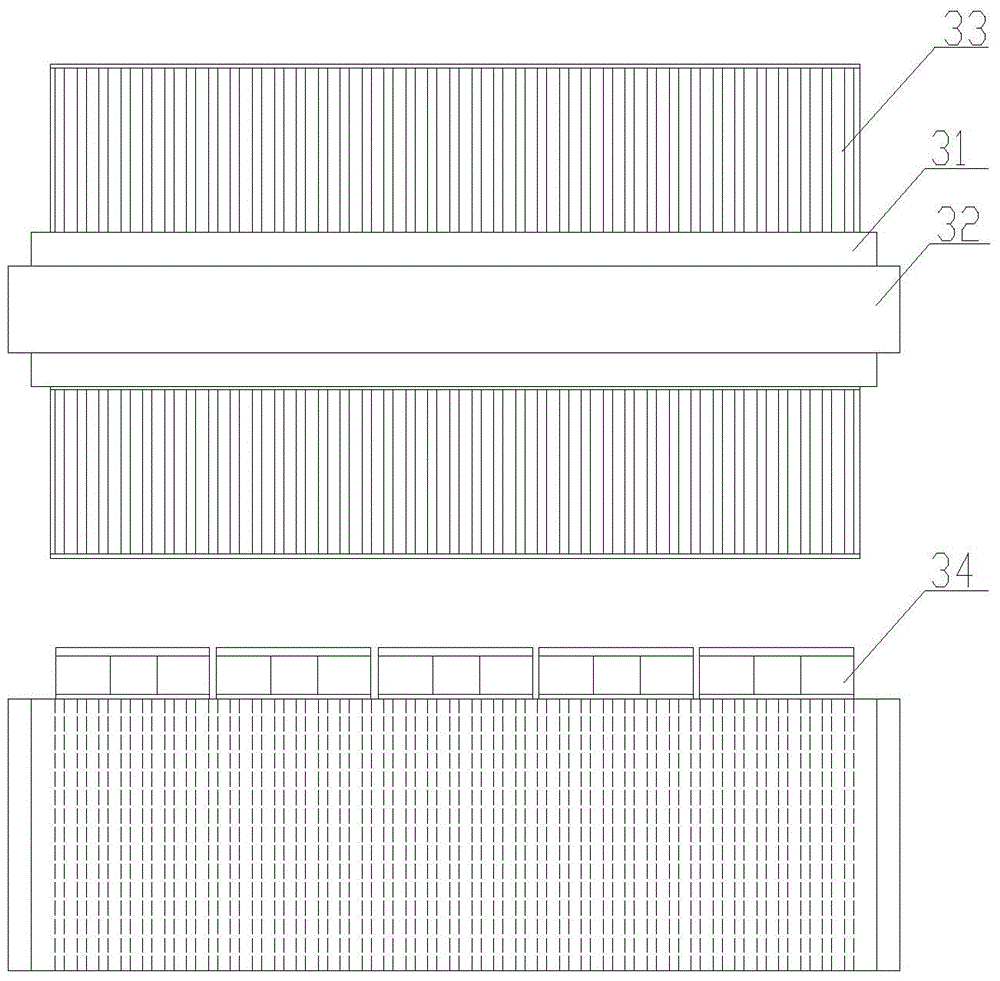

[0030] The schematic diagram of the composition of the modularized water-cooled cabinet of the present invention is as follows: figure 1 As shown, it includes a cabinet body 1, a display control unit 2, a supplementary water tank 6, a heat exchange refrigeration unit 8, a pressure conversion unit 9, a shock absorber 10, a fault alarm device 11, an ambient temperature sensor 12 and an external water-cooled electronic device 13, wherein The display control unit 2 includes an information collection module 3, an information processing module 4, a display manipulation module 5, and a status indication module 7; They are all installed on the top of the water-cooled cabinet, the fault alarm device 11 and the ambient temperature sensor 12 are installed at the bottom of the water-cooled cabinet, and a shock absorber 10 is installed at each of the four corners of the bottom of the cabinet body 1; the heat exchange refrigeration unit 8, the pressure conversion unit 9 and the external wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com