A two-phase experimental system for impingement cooling of turbine blade leading edge

A technology of turbine blades and experimental systems, applied in the field of two-phase experimental systems, can solve problems such as the inability to guarantee the stability of working fluid supply, the need to improve the response speed, and the single leading edge cooling test platform, so as to meet the requirements of high-precision experiments, Good energy-saving effect, the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

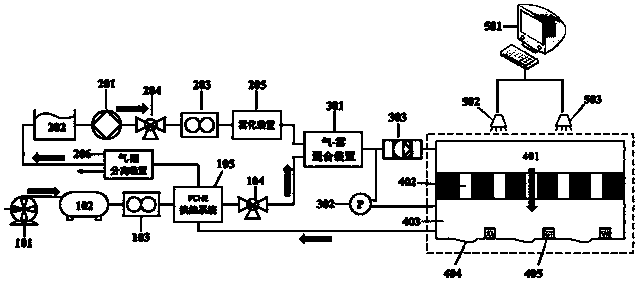

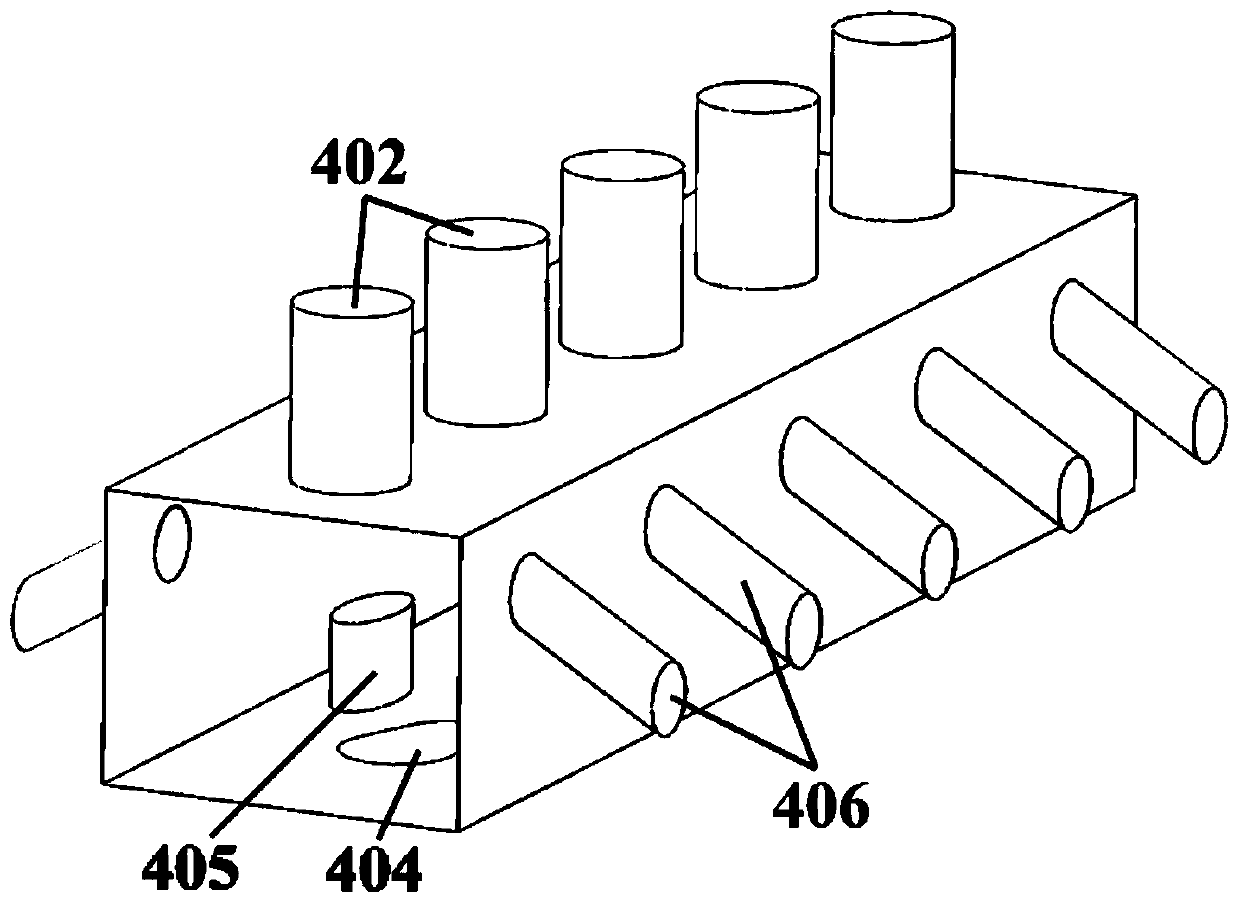

[0044] refer to figure 1 , a two-phase experimental system used for impingement cooling of the leading edge of a turbine blade provided by the present invention is used to conduct impingement cooling characteristics research, including a cooling air supply section, a water-mist circulation path, an air-mist mixing supply section, an experimental section and Data acquisition and analysis system.

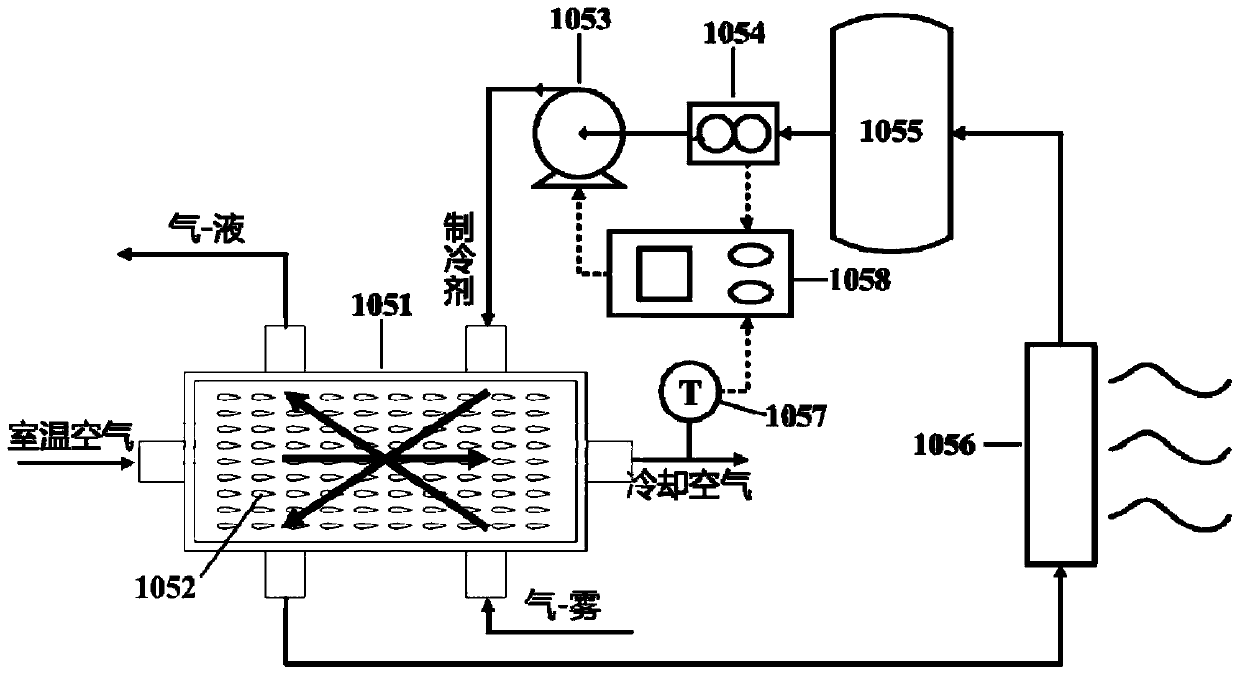

[0045] refer to figure 1 , the cooling air supply section is arranged in sequence with a high-pressure air pump 101, a steady flow air tank 102, a gas flow meter 103, a PCHE (printed circuit board type) heat exchange system 105 and a gas solenoid valve 104. Air at normal temperature enters the passage through the high-pressure air pump 101, gathers and fully mixes in the steady flow air tank 102 to provide a stable and uniform air flow, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com