A kind of through-flow condensing heat exchanger and its heat exchanging method

A condensing heat exchanger and cross-flow technology, which is applied to the cross-flow condensing heat exchanger and its heat exchange field, can solve the problems of increased condensation resistance and underutilized heat exchange area, reducing material loss, The effect of preventing re-vaporization and reducing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

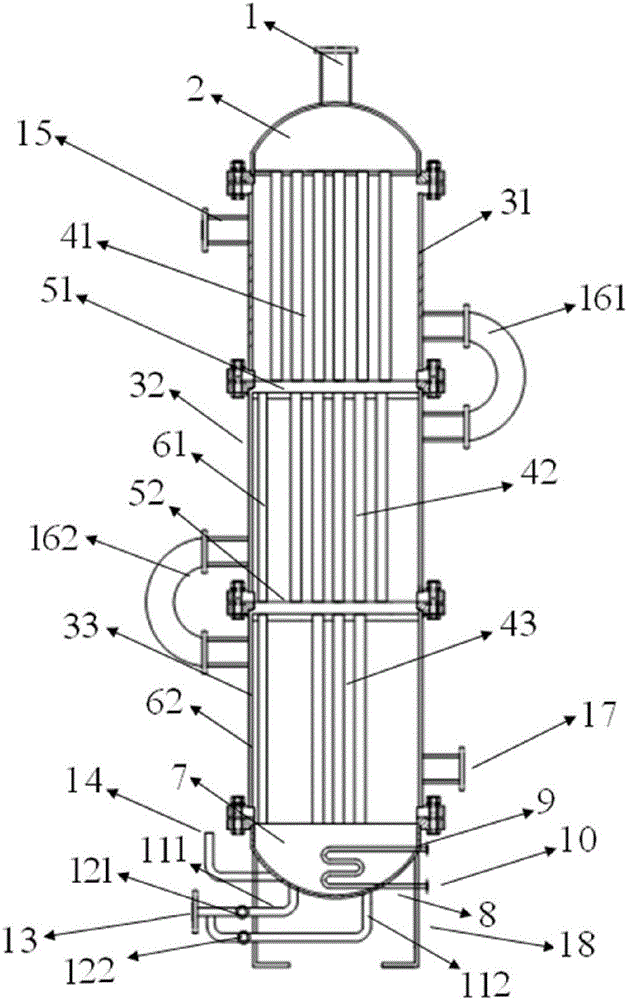

[0028] Such as figure 1 A cross-flow condensing heat exchanger shown includes a condenser body, an in-tube cooling unit and a subcooling unit. The condenser body includes a cylinder unit and a first seal head 2 and a second seal arranged on both sides of the cylinder body. Head 7, steam inlet 1 is provided on the first head 2, the cylinder unit includes a first cylinder 41, a second cylinder 42 and a third cylinder 43, the first cylinder 41 and the second cylinder 42, the first cylinder 41 The second cylinder 42 and the third cylinder 43 are respectively separated by the first vapor-liquid separator 51 and the second vapor-liquid separator 52, the cooling unit in the tube is arranged in the cylinder unit, and the supercooling unit is arranged in the second enclosure. Head 7; of which:

[0029] The in-tube cooling u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com