Patents

Literature

41results about How to "Guaranteed subcooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

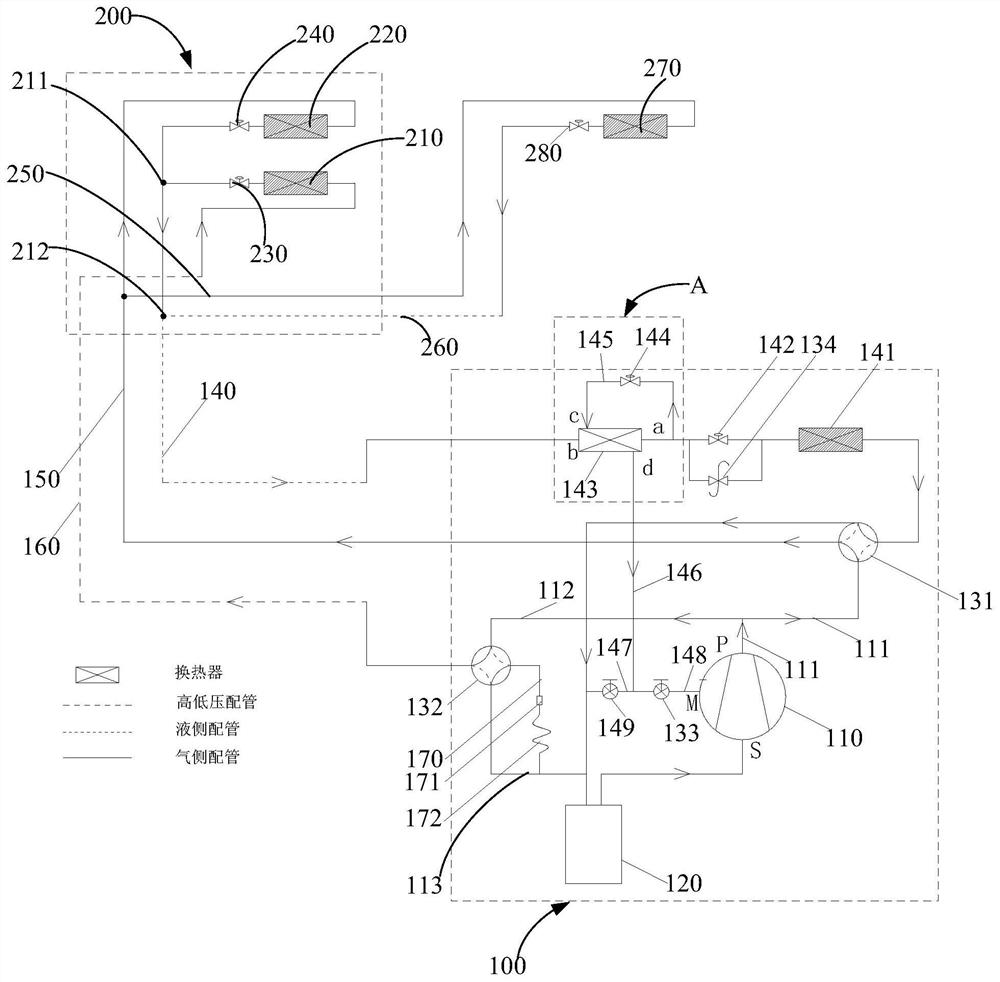

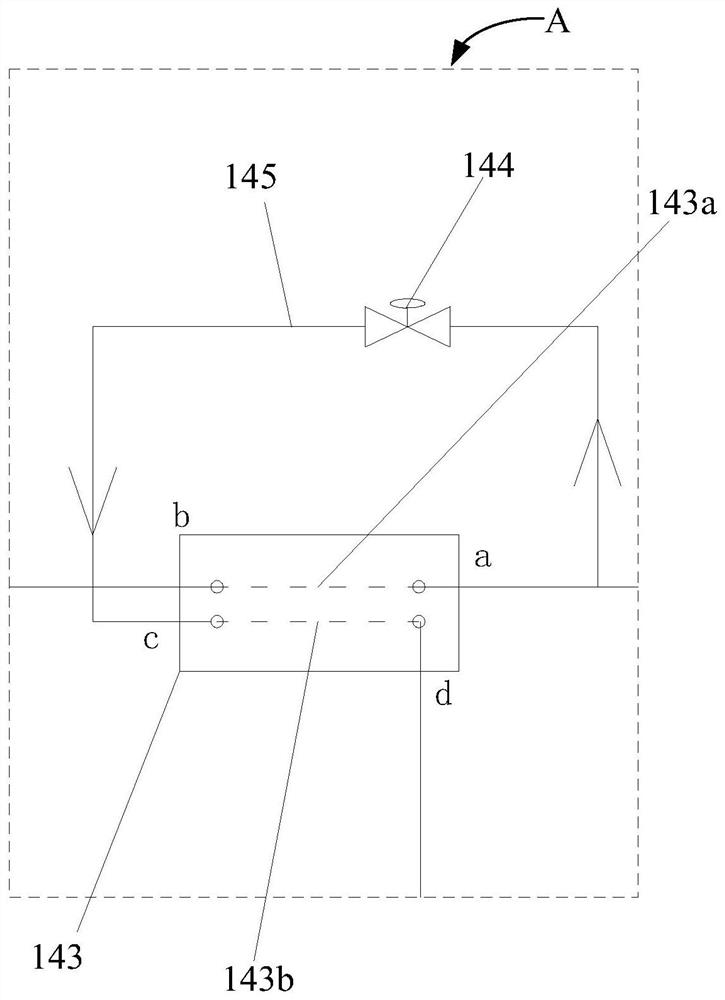

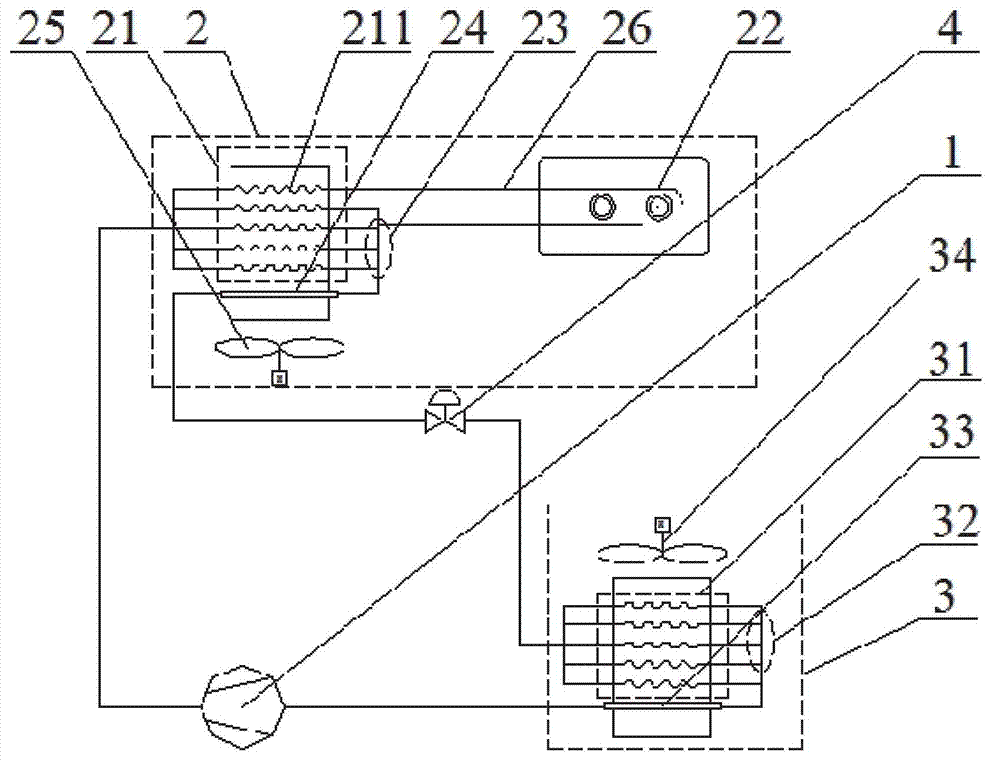

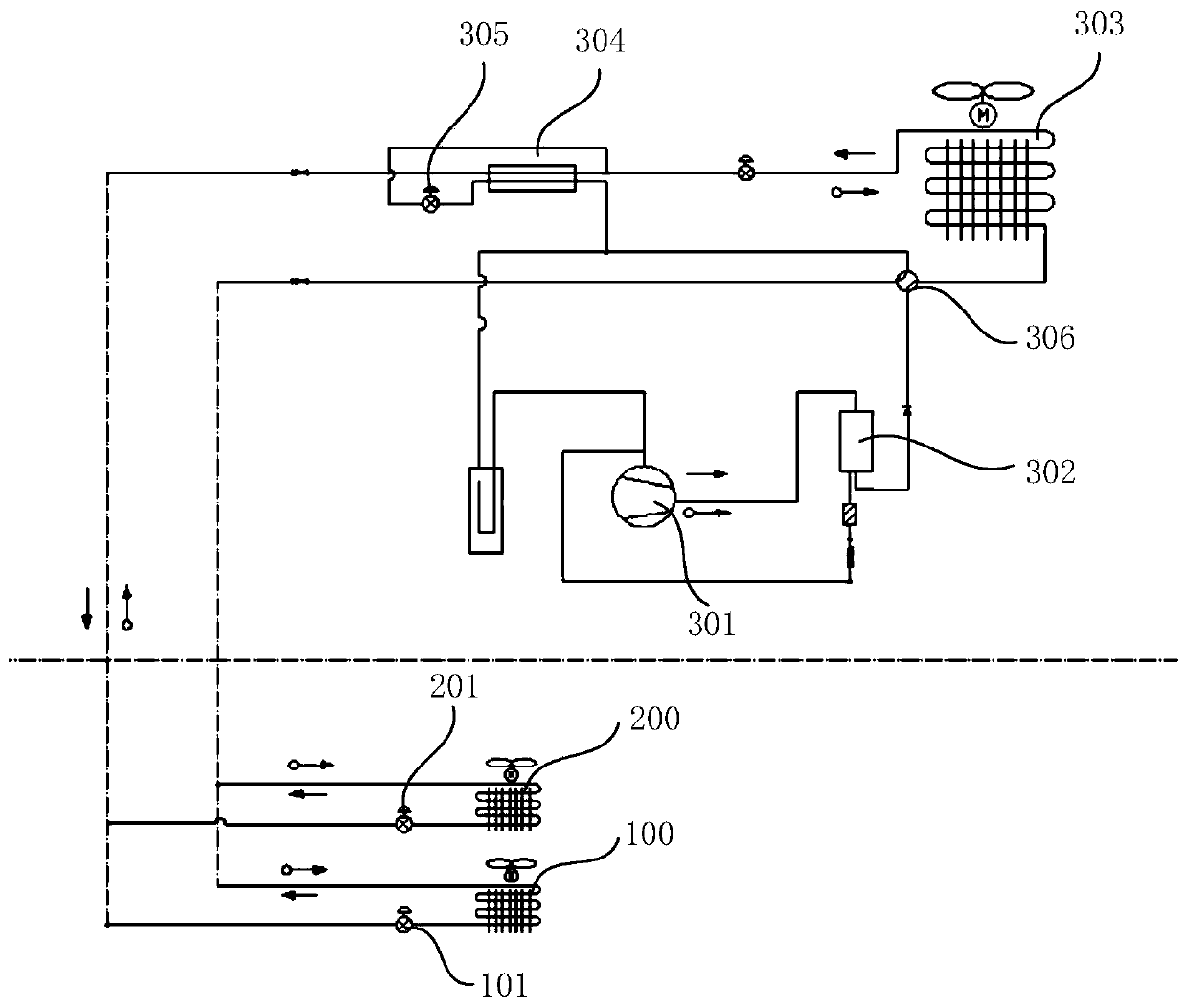

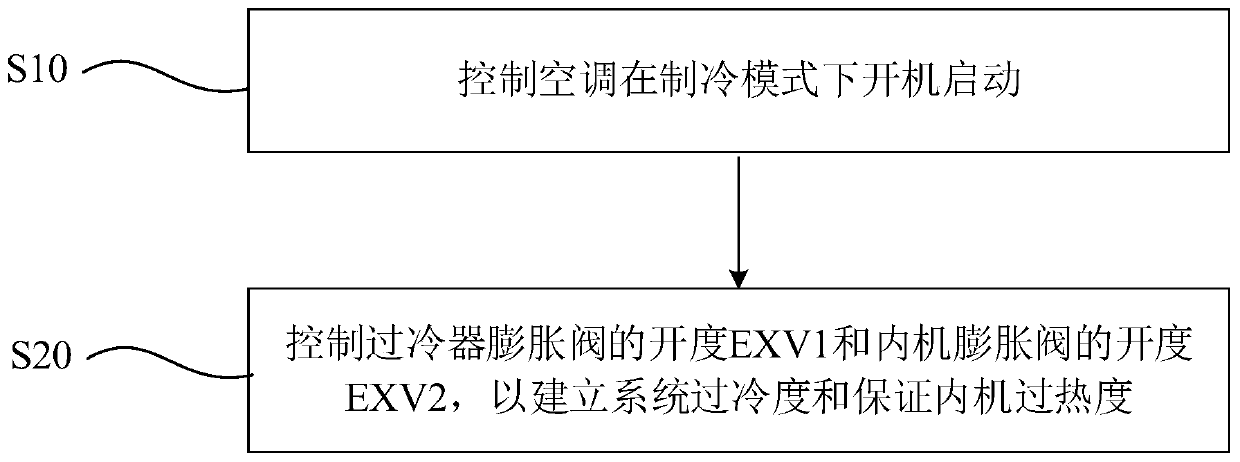

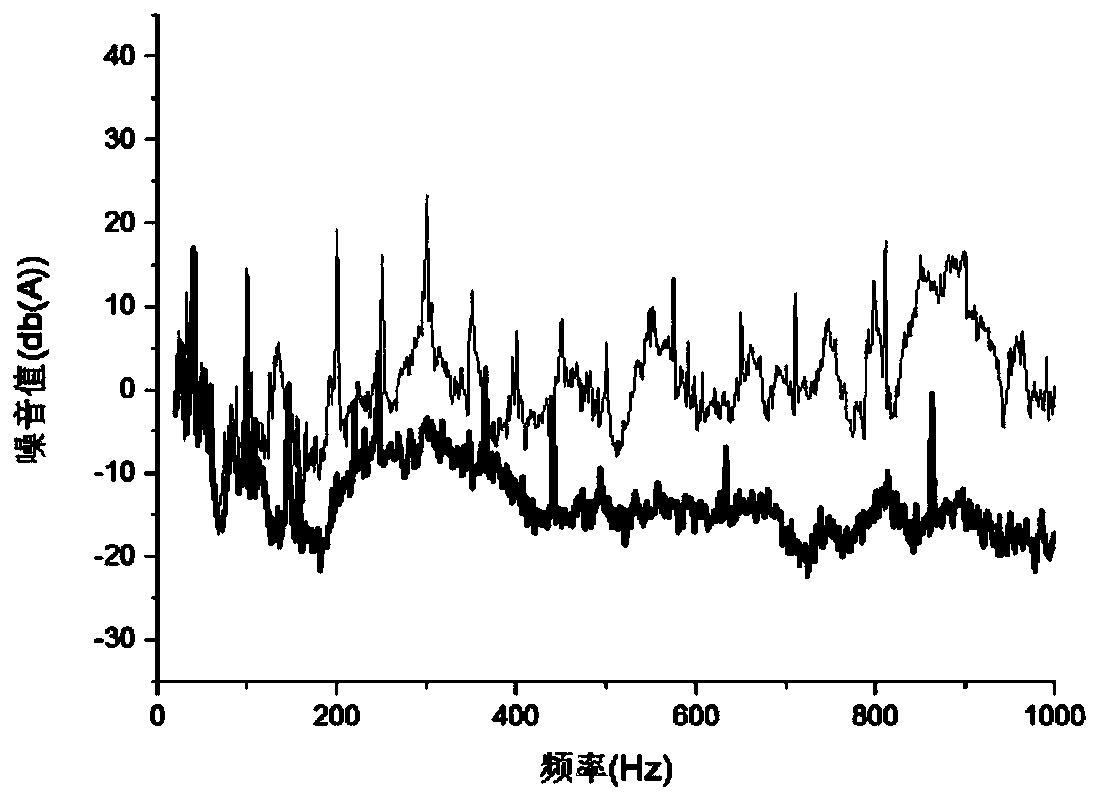

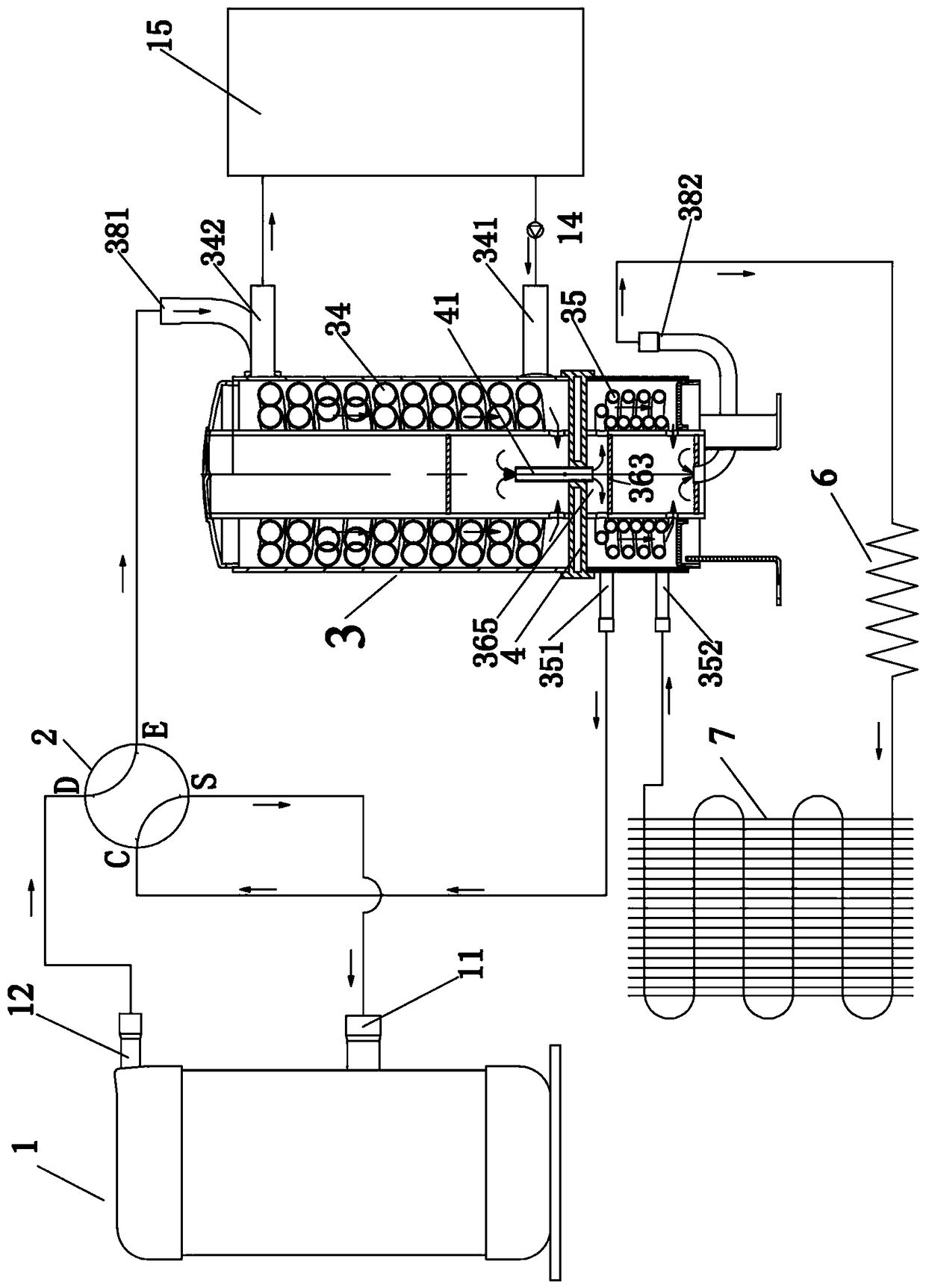

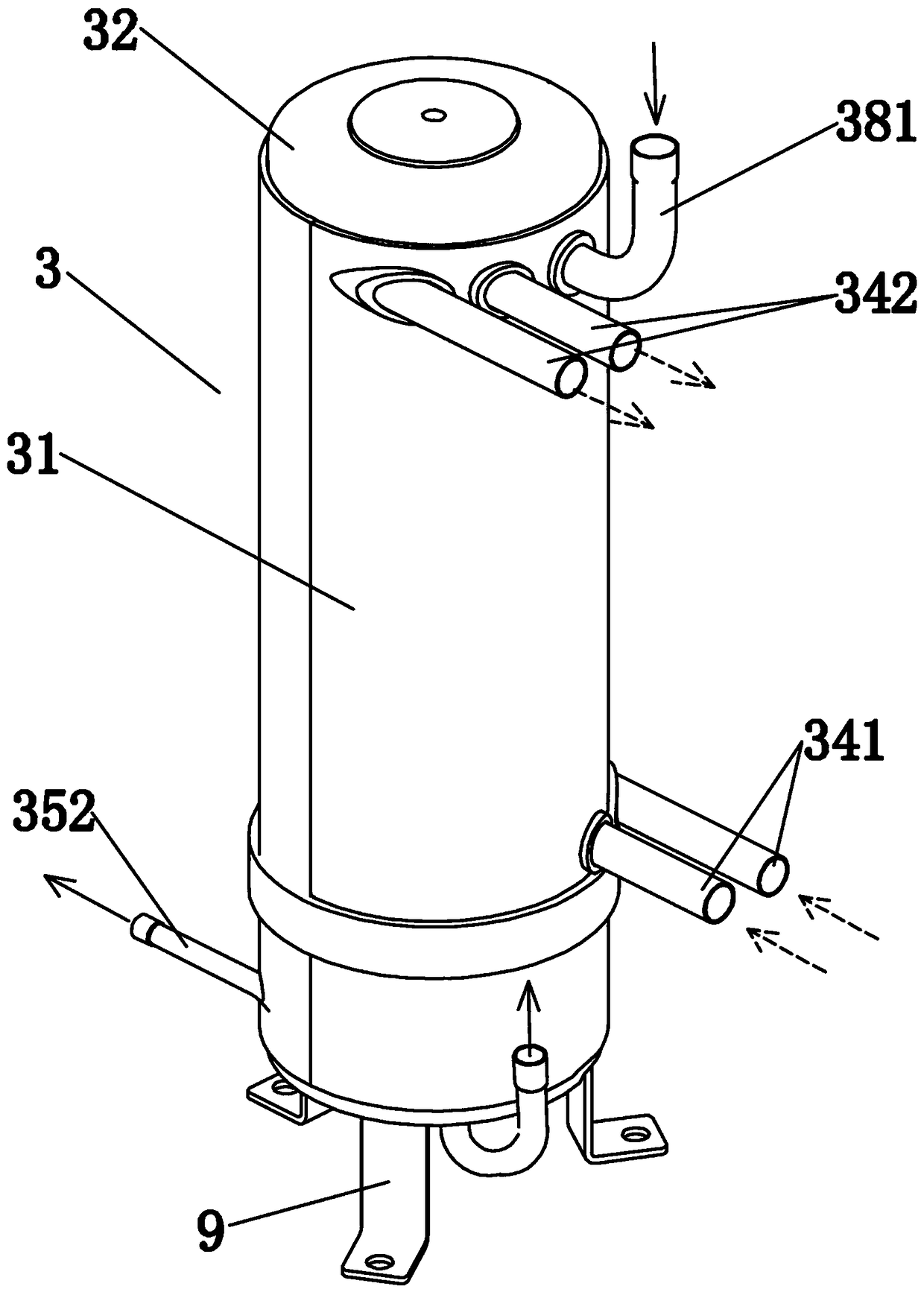

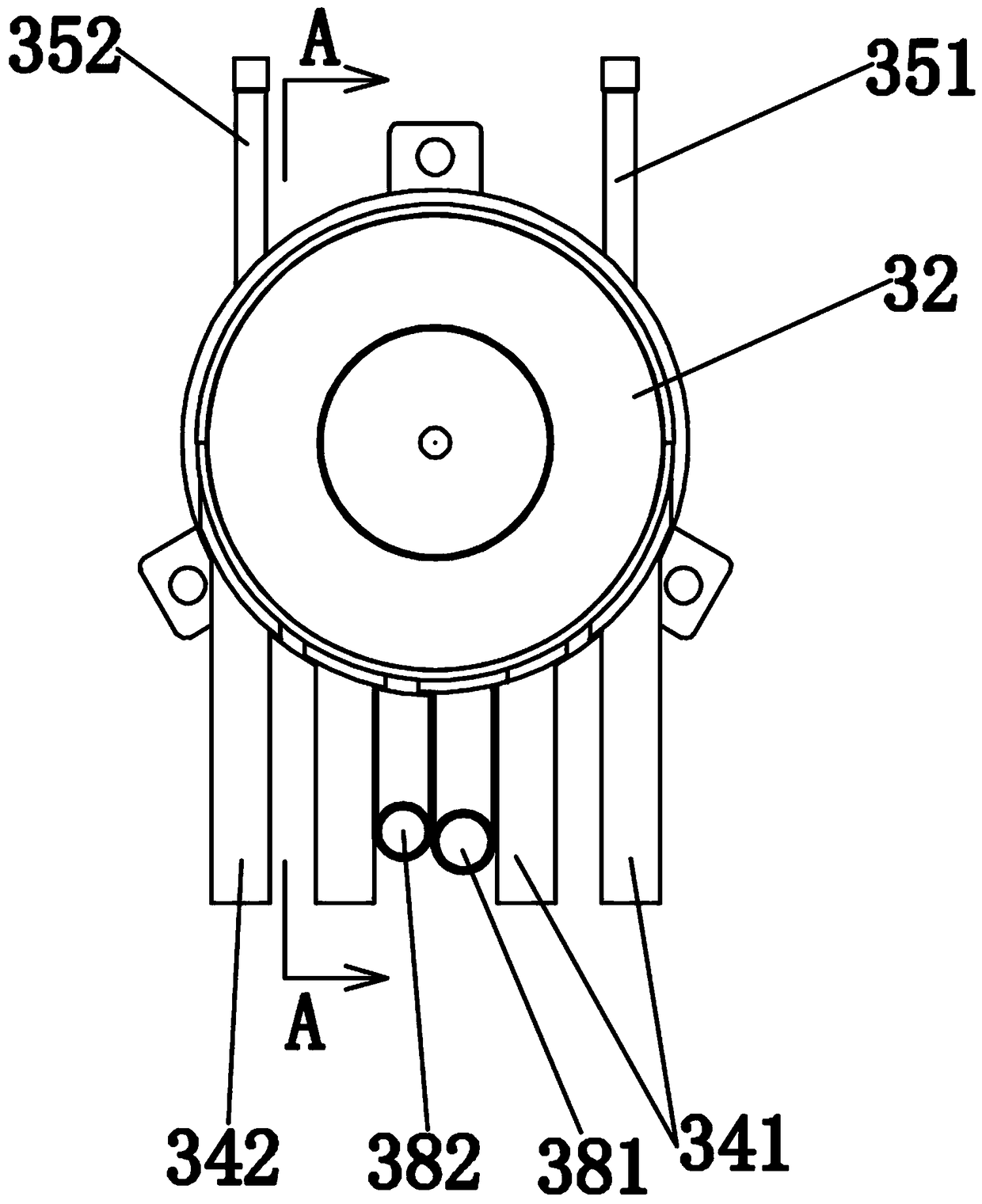

Control method for lowering noise of indoor unit of air conditioner and multi-split air conditioner

ActiveCN107062580AReduce cavitation noiseSolve the problem of liquid flow noiseMechanical apparatusSpace heating and ventilation safety systemsCavitationEngineering

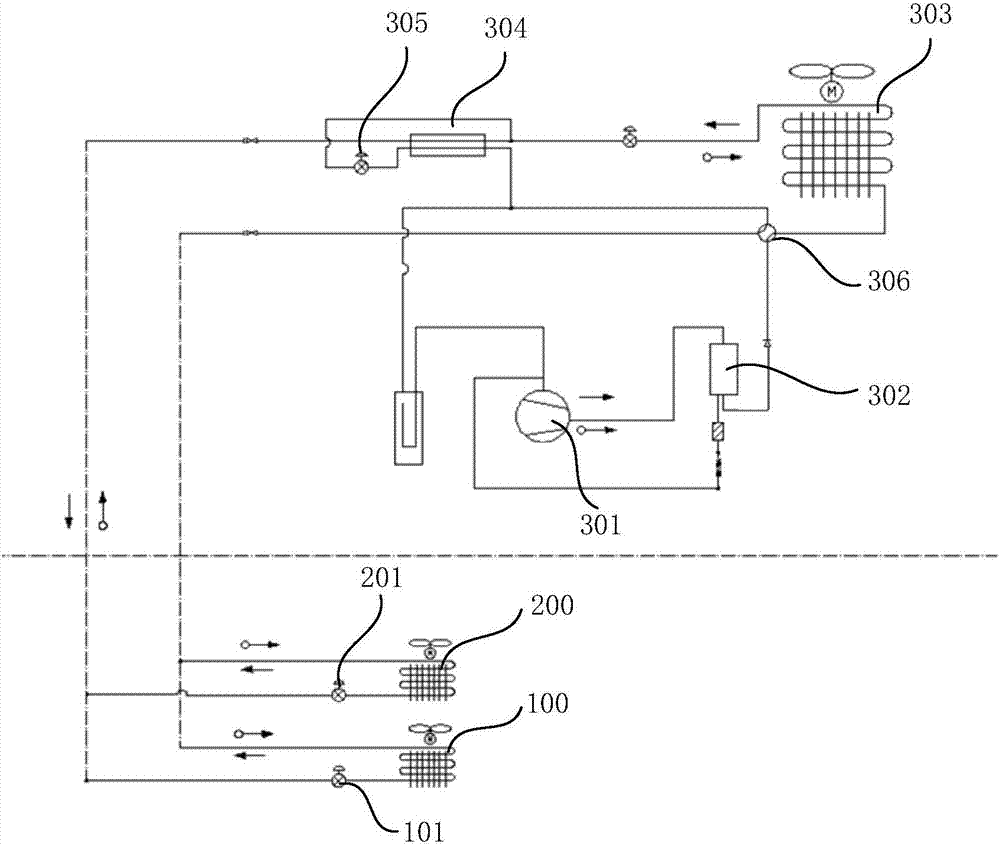

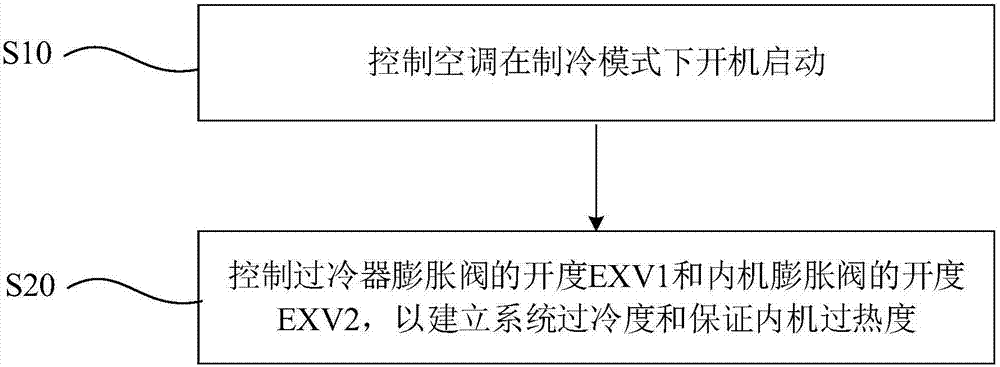

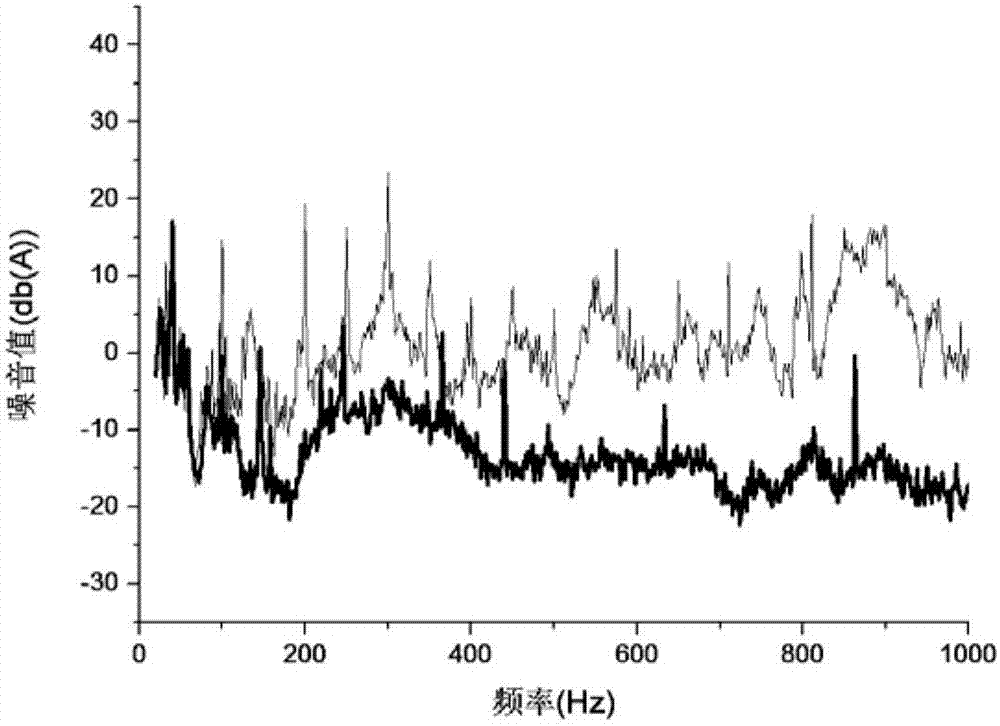

The invention discloses a control method for lowering of an indoor unit of an air conditioner. The air conditioner comprises an outdoor unit and an indoor unit. The indoor unit comprises an indoor unit expansion valve. The outdoor unit comprises a compressor and an outdoor heat exchanger. A subcooler is further arranged between the outdoor heat exchanger and the indoor unit expansion valve and comprises a subcooler expansion valve. The control method comprises the steps that S10, the air conditioner is controlled to start up in a refrigeration mode; S20, the aperture EXV1 of the subcooler expansion valve and the aperture EXV2 of the inner unit expansion valve are controlled, accordingly, the system supercooling degree is established, and the superheat degree of the indoor unit is guaranteed. By means of the control method, cavitation noise of the indoor unit during air conditioner refrigeration start running can be lowered, and then the problem of liquid flow noise of the indoor unit can be effectively solved. The invention further discloses a multi-split air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

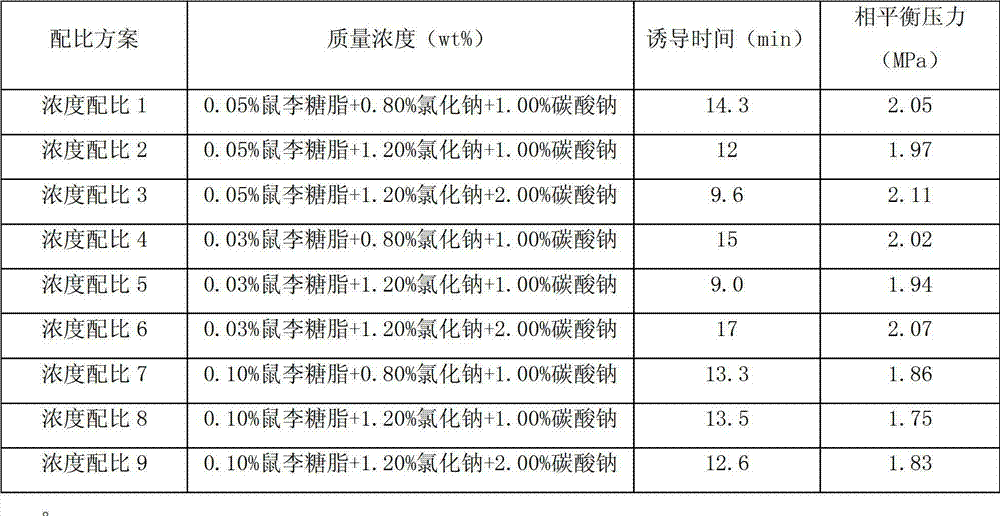

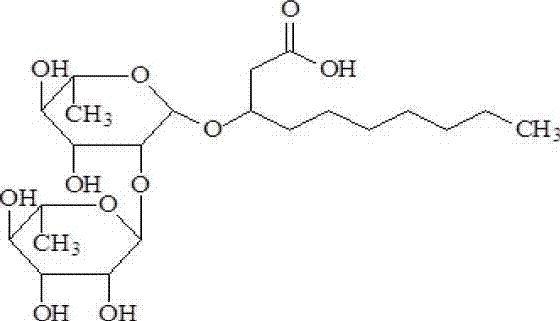

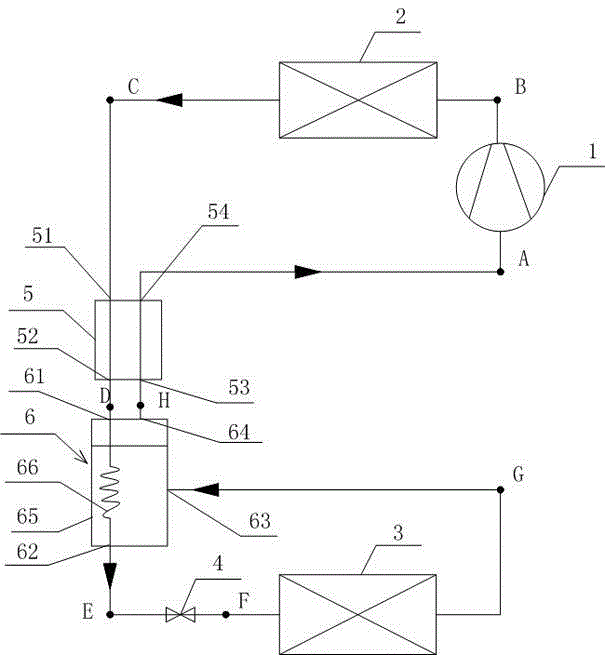

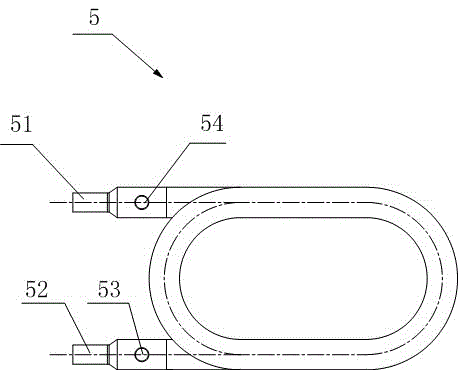

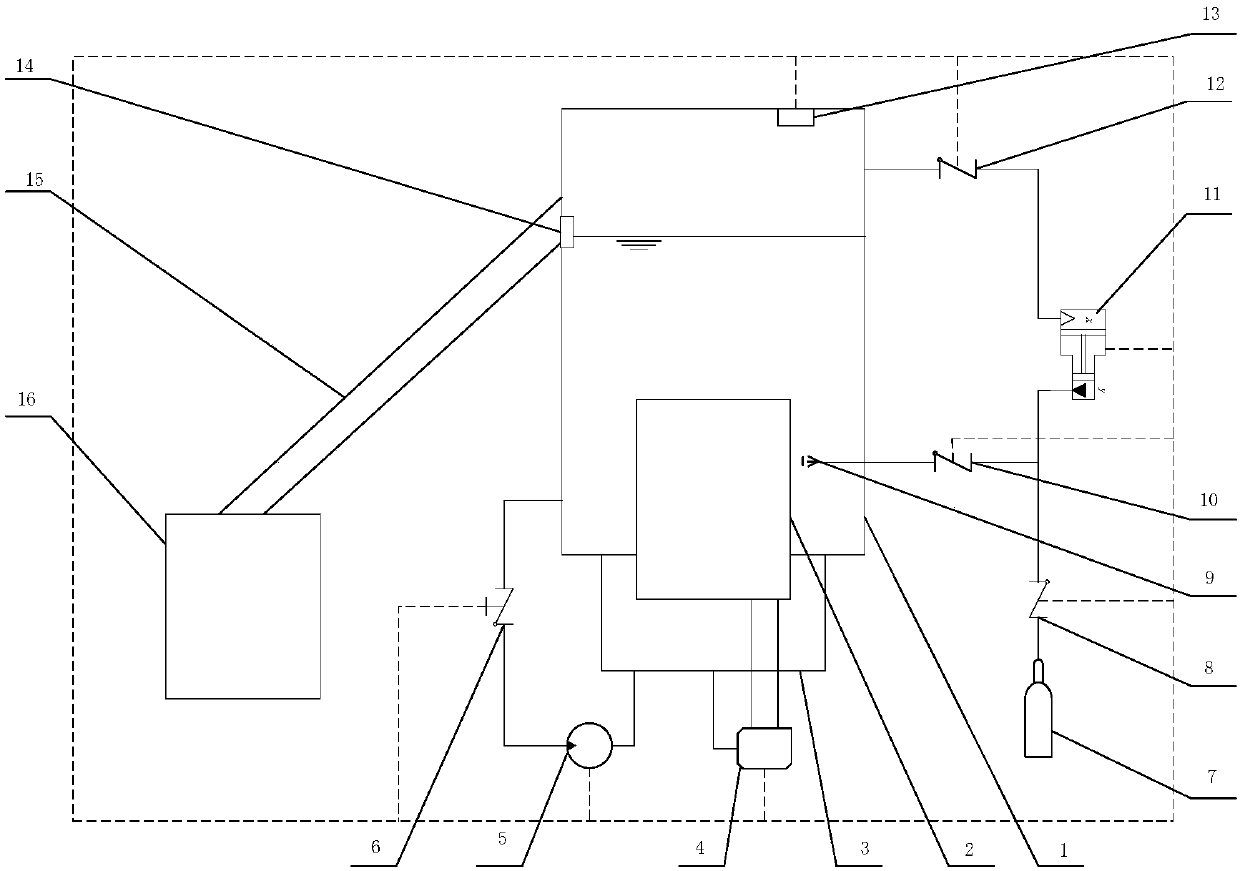

Degradable gas hydrate accelerant and preparation method thereof

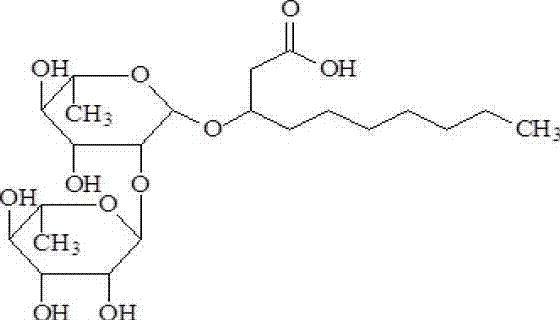

ActiveCN103028353ANon-toxicNo pollution in the processPressurized chemical processGaseous fuelsSeparation technologyGas cylinder

The invention provides a preparation method of a degradable gas hydrate efficient accelerant. The accelerant is prepared by three substances including rhamnolipid, sodium carbonate (NaCO3) and sodium chloride (NaCl) according to a certain ratio. The using mass concentration of the accelerant is 0.05-2%. The preparation method can be applied to generation acceleration research of the gas hydrate, greenhouse gas collection such as CO2 by a hydration method and fields such as gas hydrate separation technology. The preparation method is processed in a high-pressure reactor; the gas is provided by a high-pressure gas cylinder; the gas is introduced into the reactor by a pneumatic booster pump; the temperature and the pressure are displayed by a transmitter; and the reaction situation is recorded in real time by a data acquisition system through a camera. As a degradable biological surfactant used for the accelerant is very environment-friendly, the accelerant does not influence the environment and is low in cost, low in dosage, good in the acceleration effect, and beneficial to hydrate industrial production.

Owner:HAIAN GASOLINEEUM SCI RES INSTR

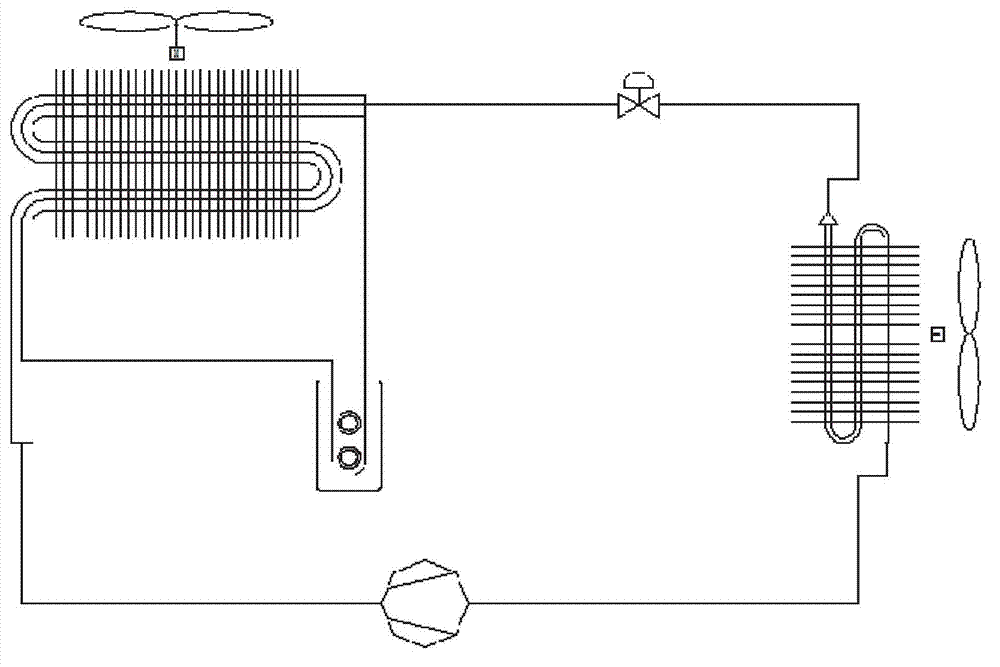

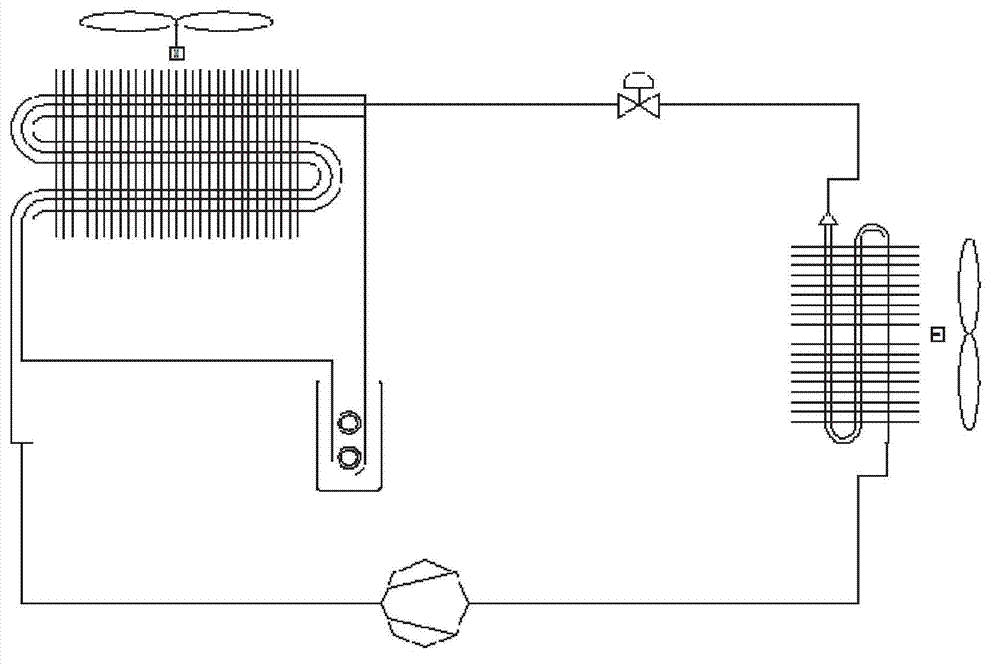

Refrigerator refrigeration circulation system

ActiveCN105865064AImprove fill rateImprove heat transfer coefficientMechanical apparatusCompression machines with non-reversible cycleEngineeringRefrigeration

The invention provides a refrigerator refrigeration circulation system. The refrigerator refrigeration circulation system comprises a compressor, a condenser, an evaporator and a capillary pipe, wherein the compressor is connected with the condenser; the capillary pipe is connected with the evaporator; the refrigerator refrigeration circulation system is further provided with a heat regenerator and a supercooling liquid accumulator; the heat regenerator is provided with a high-pressure refrigerant inlet, a high-pressure refrigerant outlet, a low-pressure refrigerant inlet and a low-pressure refrigerant outlet; the supercooling liquid accumulator is provided with a supercooling refrigerant liquid inlet, a supercooling refrigerant liquid outlet, a two-phase refrigerant inlet and a saturated refrigerant vapor outlet; the outlet of the condenser is connected with the high-pressure refrigerant inlet of the heat regenerator; the high-pressure refrigerant outlet is connected with the supercooling refrigerant liquid inlet formed in the supercooling liquid accumulator; the high-pressure refrigerant outlet is connected with the inlet of the evaporator through the capillary pipe; the outlet of the evaporator is connected with the two-phase refrigerant inlet; the saturated refrigerant vapor outlet is connected with the low-pressure refrigerant inlet; and the low-pressure refrigerant outlet is connected with the compressor. By adopting the refrigerator refrigeration circulation system, two-phase heat exchange during the whole evaporation process of the evaporator can be ensured; the heat exchange coefficient of the evaporator is obviously increased; and the heat exchange effect is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Thermal siphon oil cooling system

ActiveCN104567060AEfficient use ofSave energyMechanical apparatusCompression machines with non-reversible cycleThermodynamicsEngineering

The invention discloses a thermal siphon oil cooling system which comprises a thermal siphon liquid accumulator, a condenser, a high pressure liquid accumulator, a condenser liquid outlet pipe and a thermal siphon liquid accumulator overflow pipe, wherein an overflow port of the thermal siphon liquid accumulator and the high pressure liquid accumulator are communicated through the thermal siphon liquid accumulator overflow pipe. One end of the condenser liquid outlet pipe is connected with a liquid outlet of the condenser, and the other end of the condenser liquid outlet pipe is connected with the thermal siphon liquid accumulator overflow pipe. The thermal siphon oil cooling system has the advantages of being simple in structure, convenient to reform, safe, reliable and capable of saving energy.

Owner:SINOHYDRO BUREAU 8 CO LTD

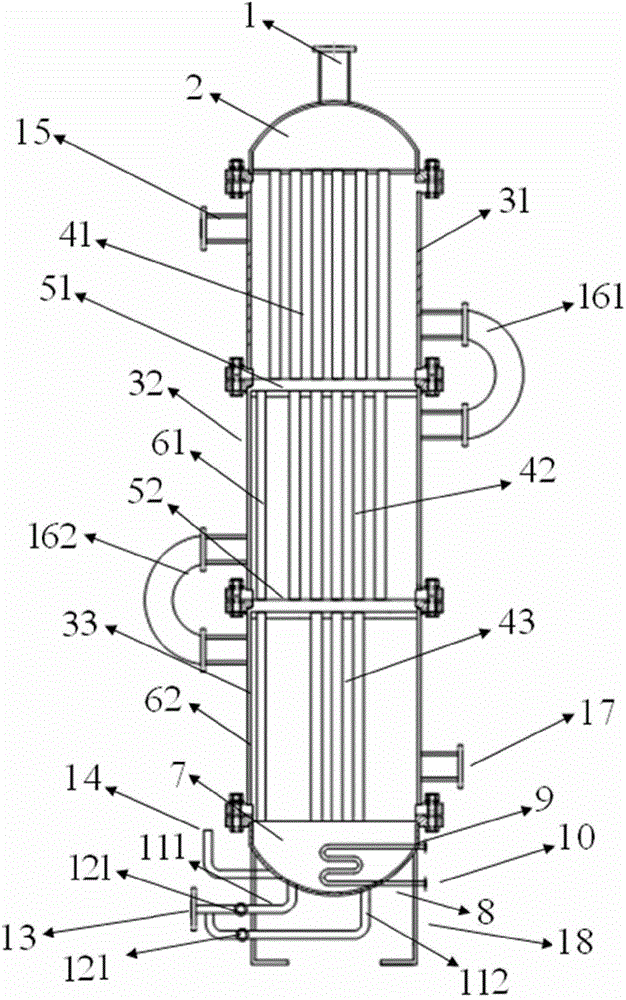

Two-stage heat exchanger

ActiveCN105546885AImprove heat transfer efficiencyGuaranteed subcoolingEvaporators/condensersPlate heat exchangerEngineering

The invention relates to a two-stage heat exchanger. According to the two-stage heat exchanger, the interior of a shell is divided into a first-stage heat exchange cavity and a second-stage heat exchange cavity through a partition plate, the first-stage heat exchange cavity communicates with the second-stage heat exchange cavity through a communicating channel on the partition plate, a first-stage heat exchange pipe is arranged in the first-stage heat exchange cavity, and a second-stage heat exchange pipe is arranged in the second-stage heat exchange cavity. When the two-stage heat exchanger is used as a condenser and the supercooling degree of the first-stage heat exchange pipe is small, the second-stage heat exchange pipe can be put into use together; firstly, superheated refrigerant steam in the first-stage heat exchange cavity rapidly exchanges heat with cooling liquid in the first-stage heat exchange pipe and then is condensed into liquid refrigerant; then, the liquid refrigerant enters the second-stage heat exchange cavity, the liquid refrigerant in the second-stage heat exchange pipe is evaporated or saturated refrigerant steam absorbs heat of the liquid refrigerant, and therefore the refrigerant in the second-stage heat exchanger can be sufficiently supercooled before throttling, the supercooling degree of a refrigerant system is kept, the pressure of the refrigerant system and loads on a compressor are reduced, and overall energy efficiency of a unit can be improved.

Owner:FOSHAN GUANGTENG NEW ENERGY CO LTD

Undercooling type condensation heat exchanger and heat exchange method thereof

ActiveCN104390495ARealize heat exchange in seriesControlling the condensation heat transfer rateStationary tubular conduit assembliesEngineeringVapor–liquid separator

The invention provides an undercooling type condensation heat exchanger and a heat exchange method thereof. The condensation heat exchanger comprises a condenser body, an in-tube cooling unit and an undercooling unit. The condenser body comprises a cylinder unit, a first end enclosure and a second end enclosure, and the first end enclosure and the second end enclosure are arranged on two sides of the cylinder unit respectively. The first end enclosure is provided with a steam inlet and a steam outlet. The cylinder unit comprises a first cylinder and a second cylinder which are separated from each other through a gas-liquid separator. A separation plate is arranged in the first end enclosure, the in-tube cooling unit is arranged in the cylinder unit, and the undercooling unit is arranged in the second end enclosure. A steam heat exchange process in heat exchange tubes is divided into two processes in the two cylinders by the separation plate, and flow velocity of steam in each process is kept uniform basically; through heat exchange of the undercooling unit and the in-tube cooling unit, reliability in heat exchange is guaranteed, and application range of the condensation heat exchanger is widened.

Owner:福建蓝海节能科技有限公司

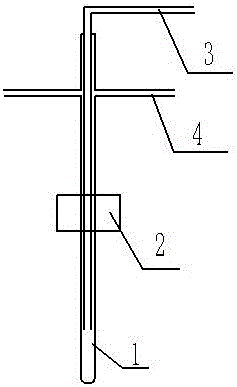

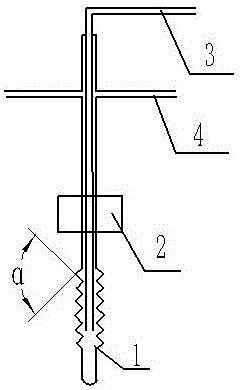

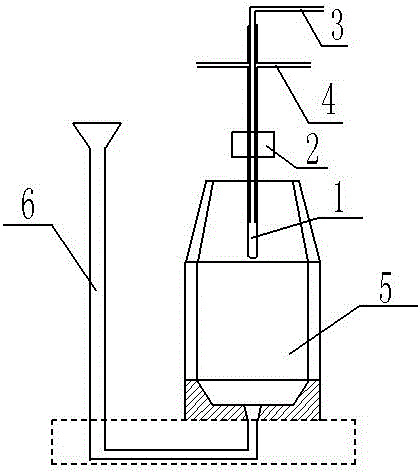

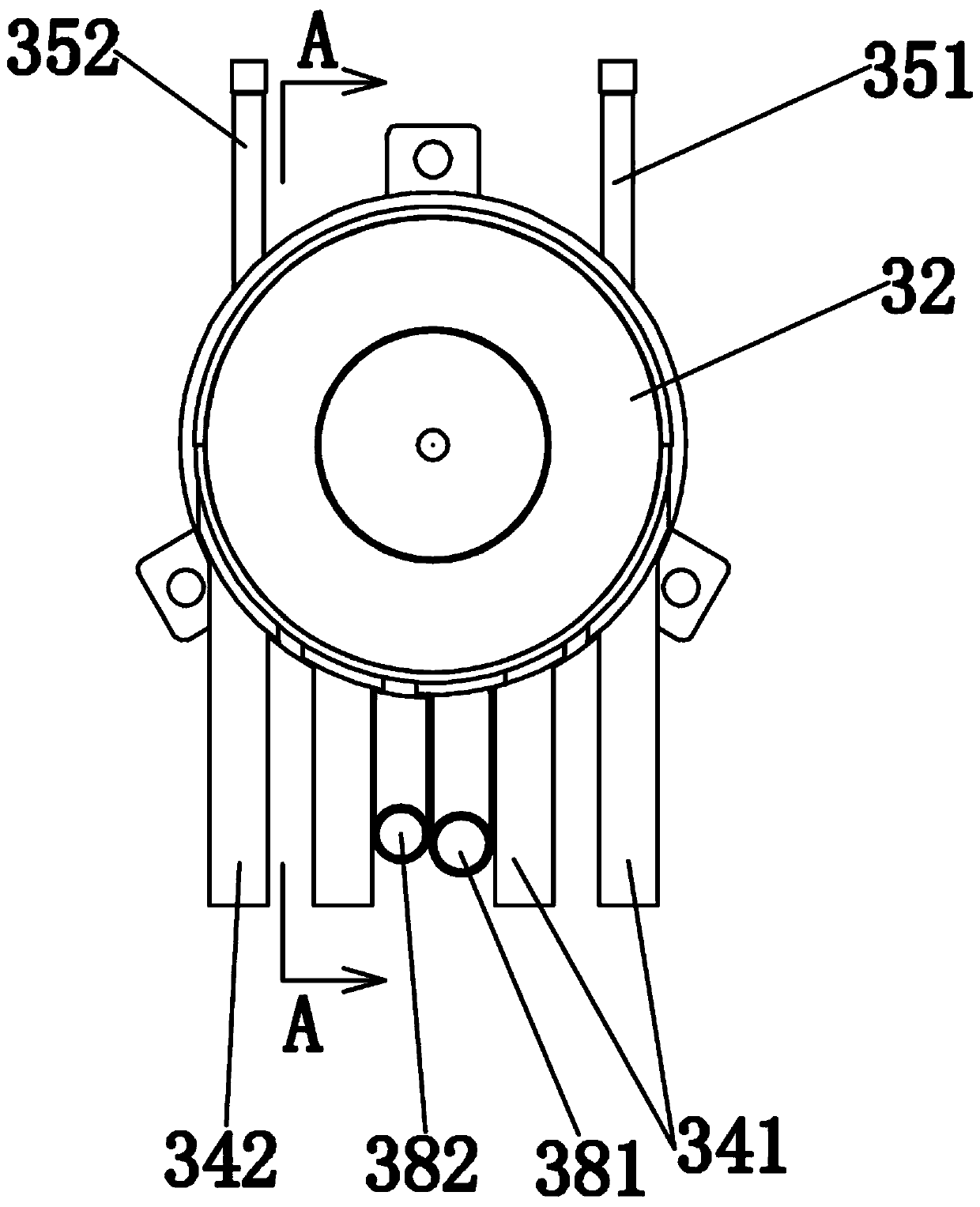

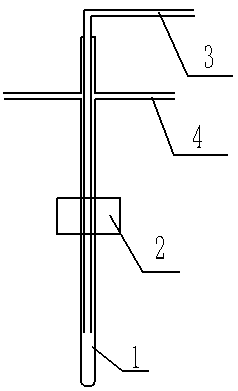

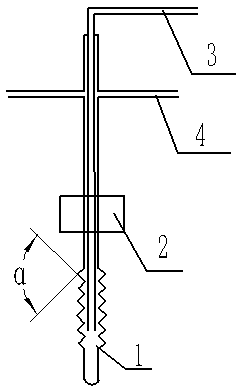

Device for refining grain structure and application method

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

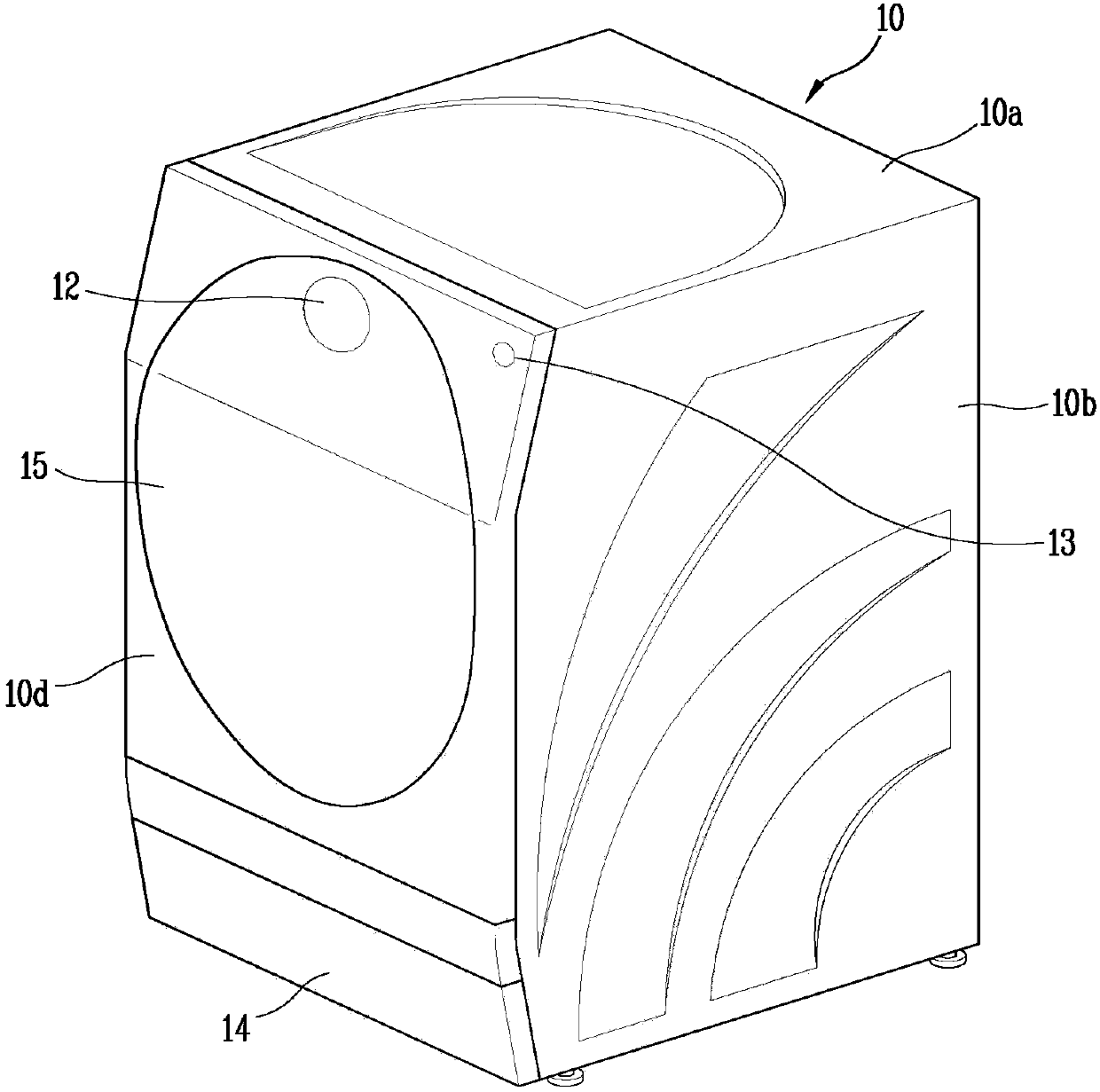

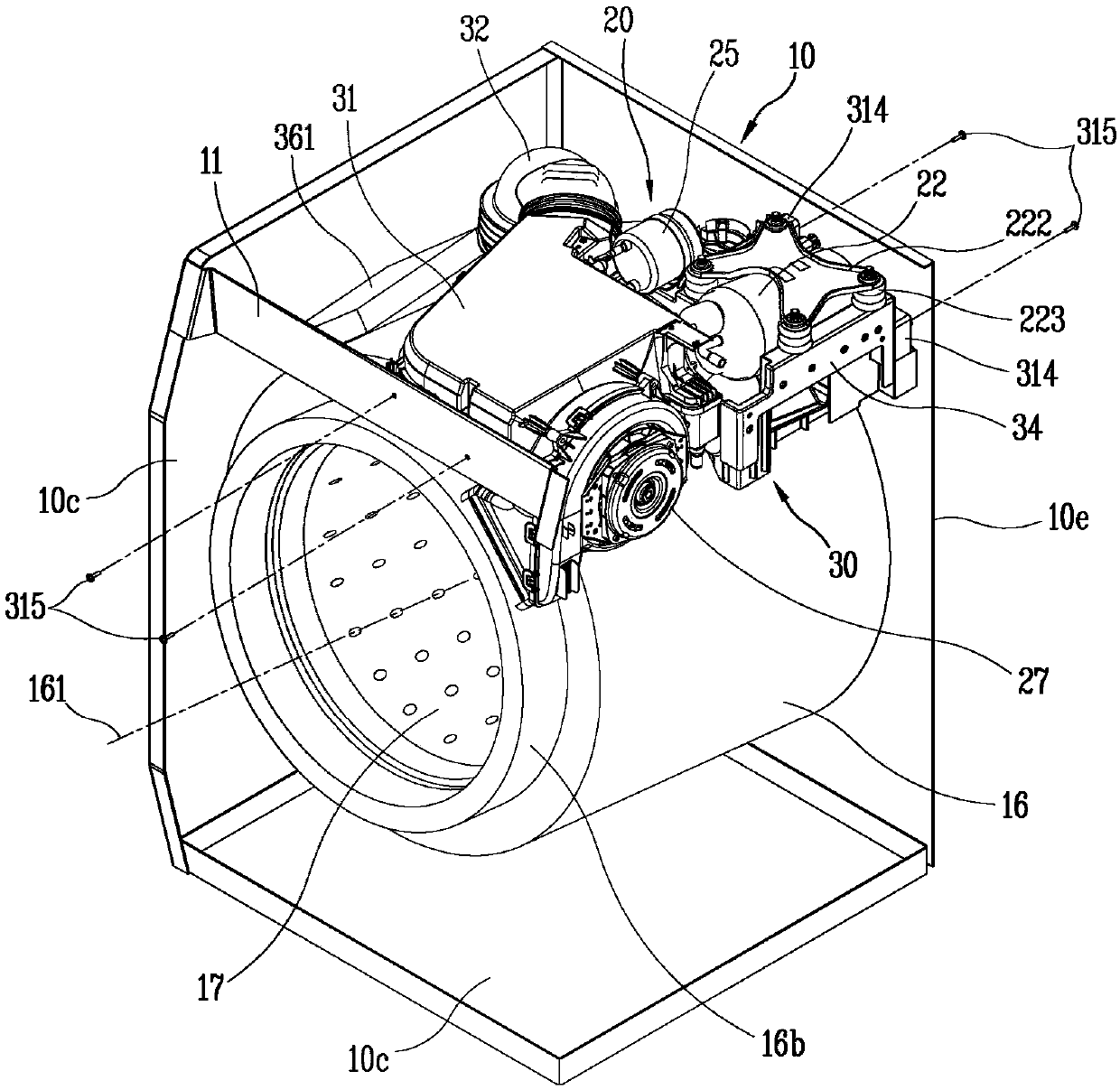

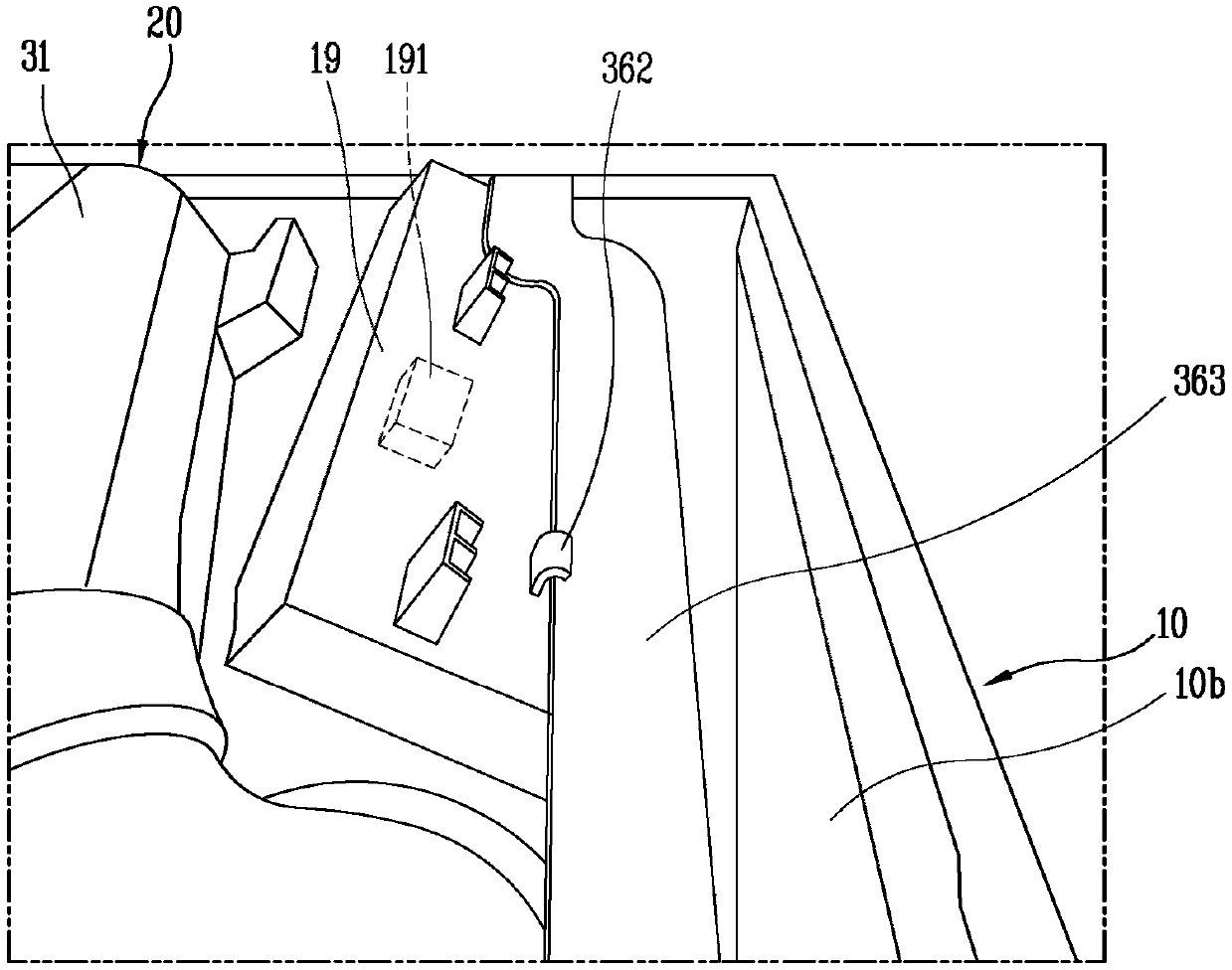

Clothes treatment apparatus

ActiveCN107675453AIncrease the heat exchange areaImprove utilizationTextiles and paperLaundry driersEngineeringRefrigerant

The invention discloses a clothes treatment apparatus, including a drum rotatably provided within a cabinet to accommodate washing and drying objects; and a heat pump module including an evaporator, acompressor, a condenser, and an expansion valve, through which a refrigerant is circulated, to provide heat to air discharged from the drum and circulated to the drum, wherein the heat pump module further includes an internal heat exchanger configured to exchange heat between the refrigerant discharged from the condenser and the refrigerant passing through the evaporator.

Owner:LG ELECTRONICS INC

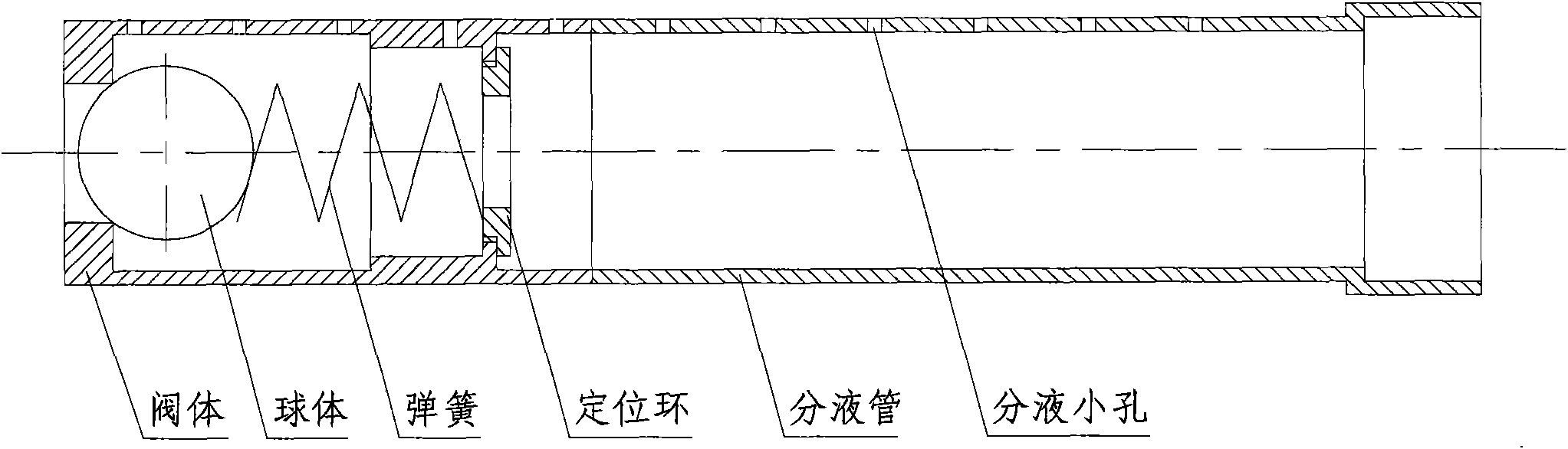

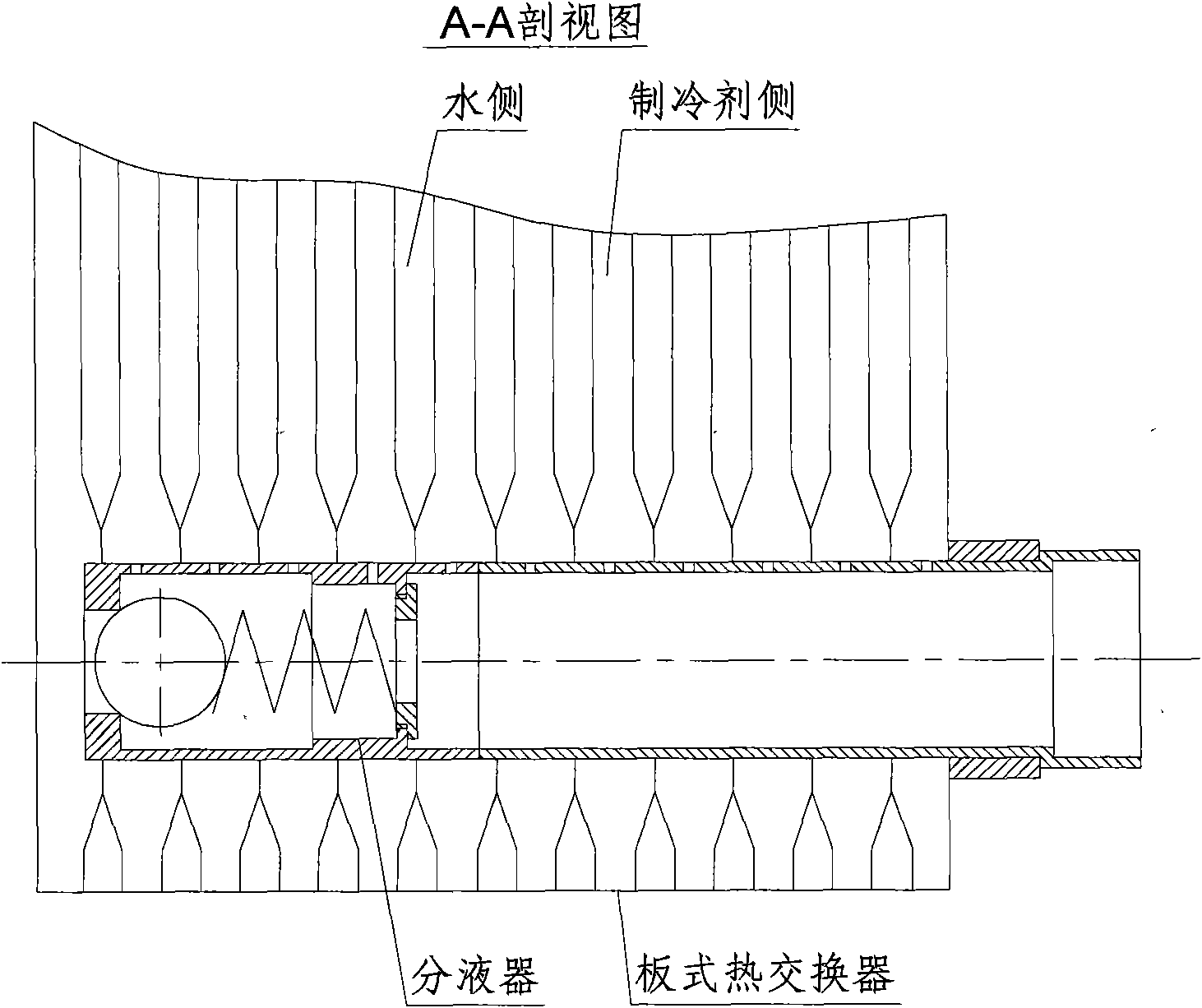

Novel plate type heat exchanger liquid divider

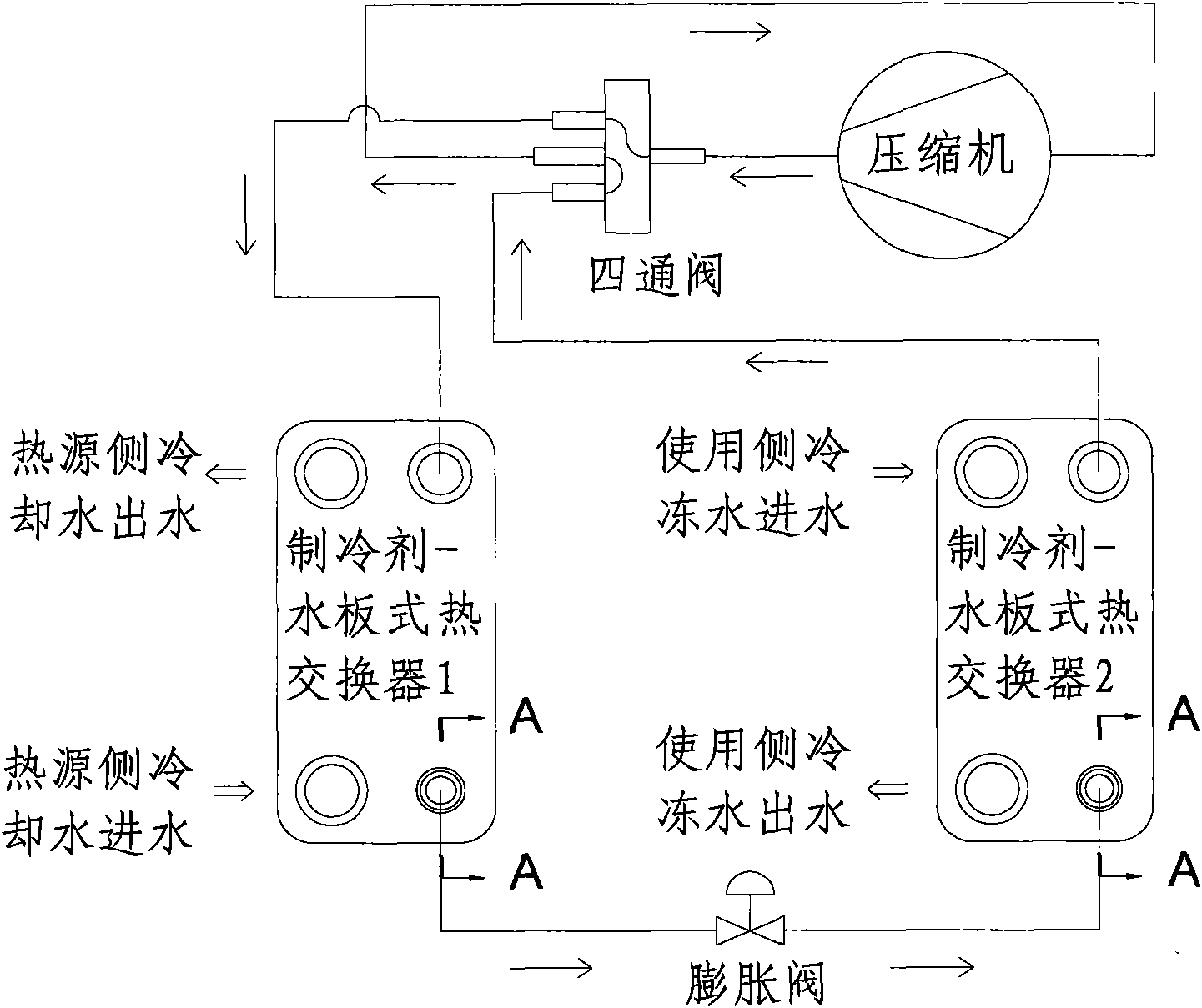

InactiveCN101988776AGuaranteed subcoolingHeat pumpsEvaporators/condensersSuper coolingFour-way valve

The invention relates to a novel plate type heat exchanger liquid divider which belongs to the technical field of a refrigeration air conditioning machine set equipped with a plate type heat exchanger and utilizing a four-way valve for carrying out refrigeration and heating switching. The invention aims at breaking through the technical bottle neck that a refrigerating agent is distributed unevenly in plate sheets when the plate type heat exchanger is used as an evaporator, and by the invention, the refrigerating agent can be uniformly distributed into each plate sheet of the plate type heat exchanger and the heat exchange efficiency and the energy saving effect can be improved, and meanwhile, the use effect of the plate type heat exchanger used as a condenser can be ensured after the refrigeration and heating switching. In order to solve the problem, the invention has the main technical scheme that the novel plate type heat exchanger liquid divider is additionally arranged at the side of a refrigerating fluid pipe of the plate type heat exchanger, the throttled refrigerating agent is uniformly distributed into each plate sheet through small liquid dividing holes when the plate type heat exchanger is used as an evaporator, and super-cooling liquid flows out from the plate type heat exchanger from a one-way valve of the liquid divider after the refrigerating and heating switching when the plate type heat exchanger is used as a condenser.

Owner:深圳市得益节能科技股份有限公司

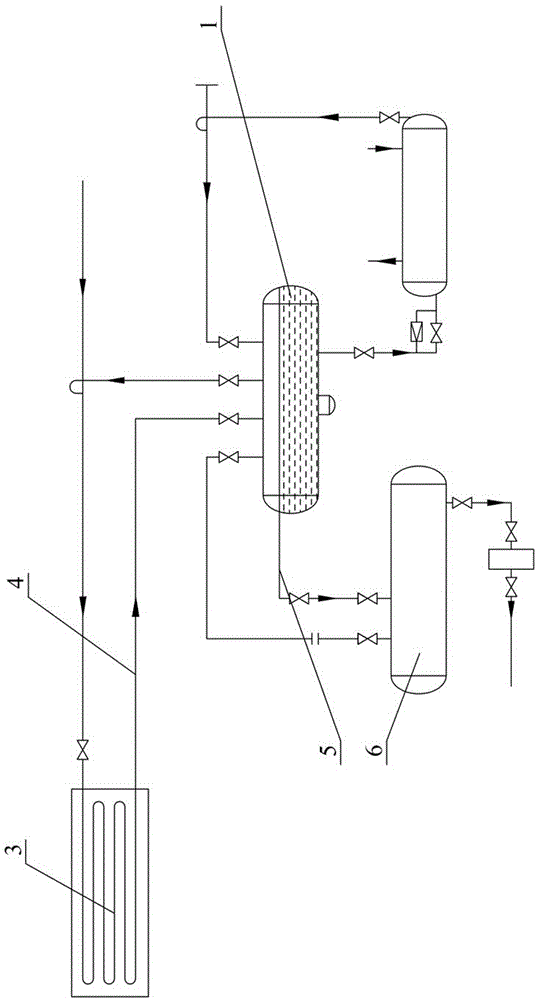

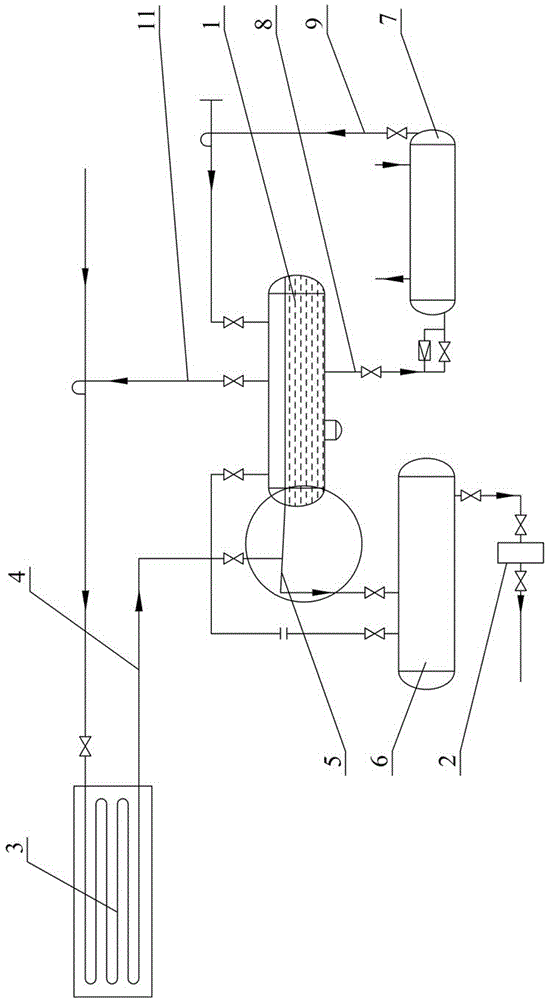

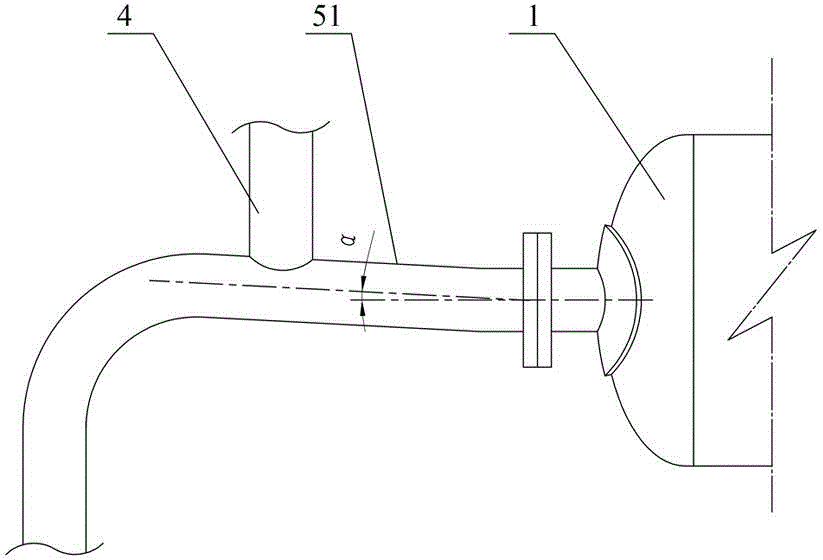

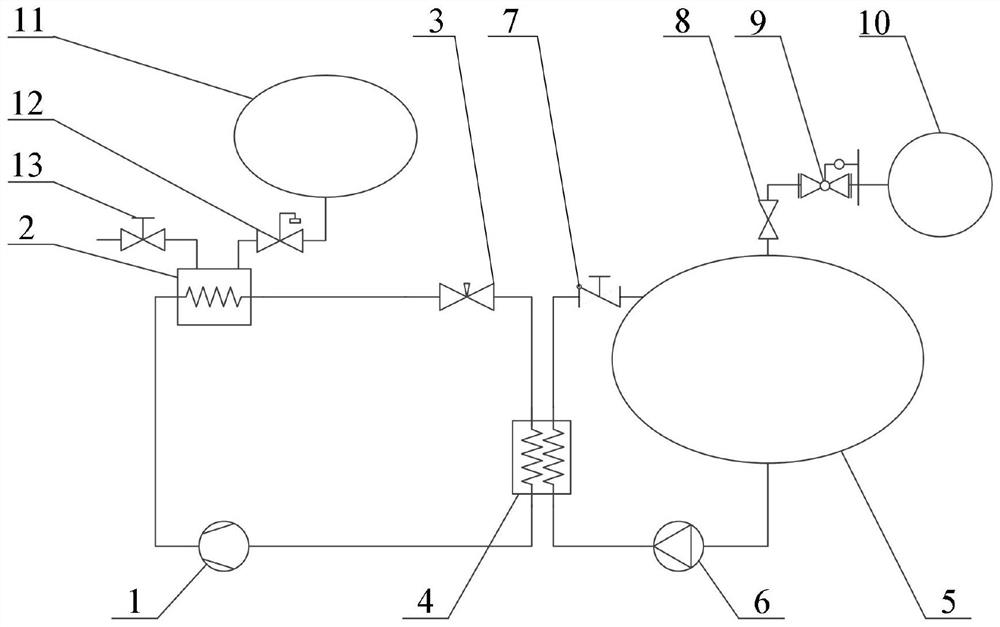

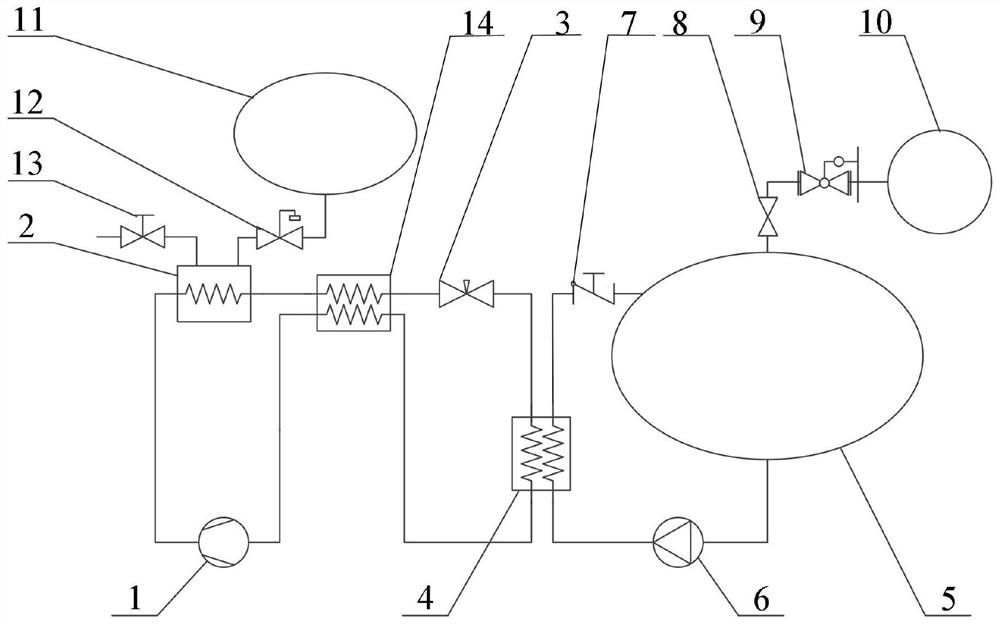

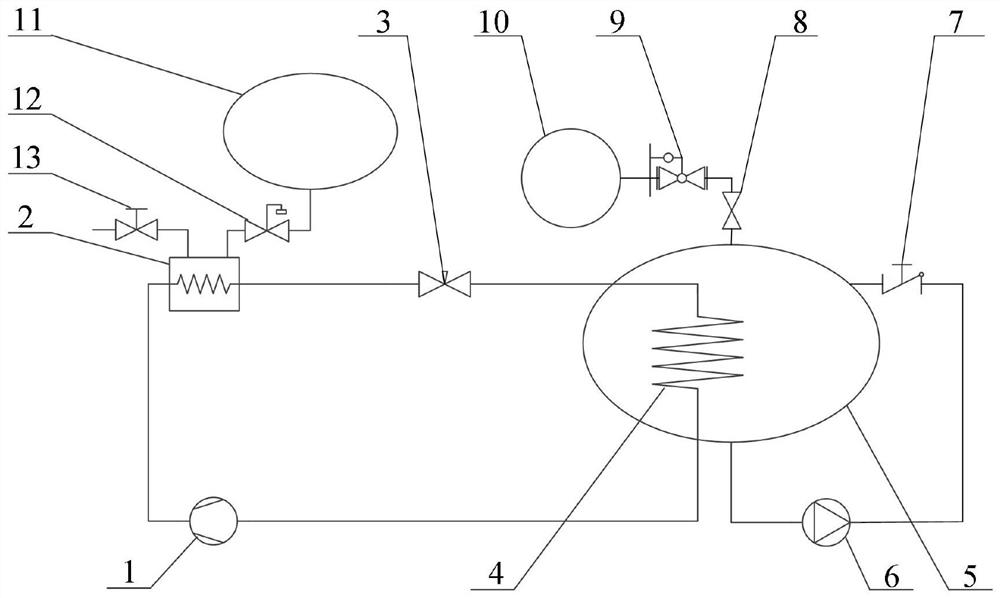

Liquid hydrogen supercooling degree acquisition system for space launching site

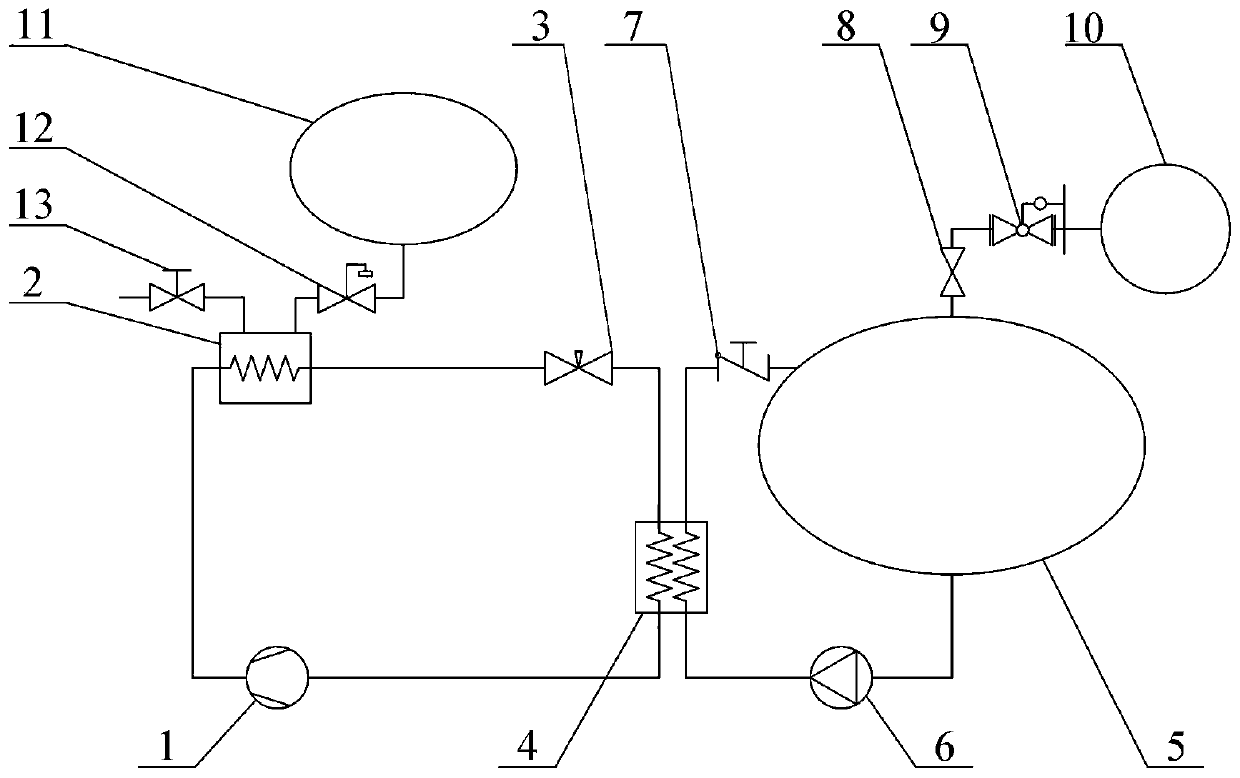

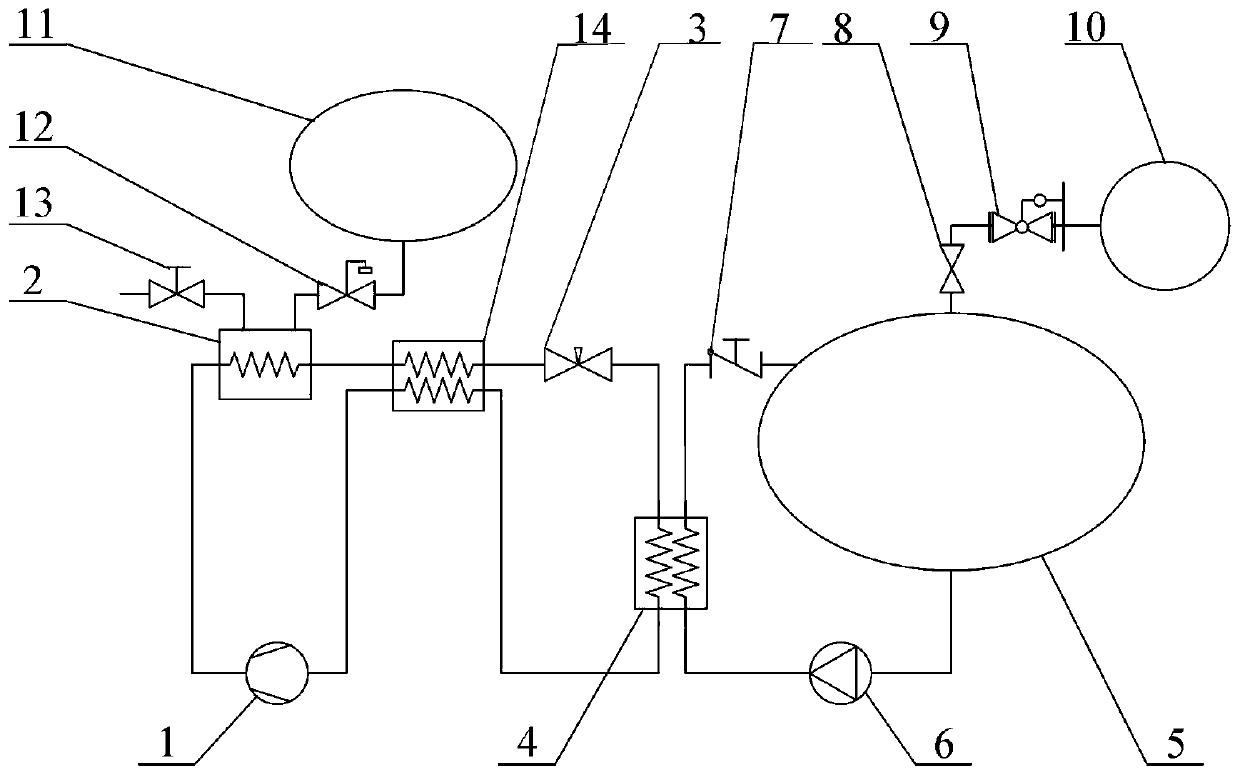

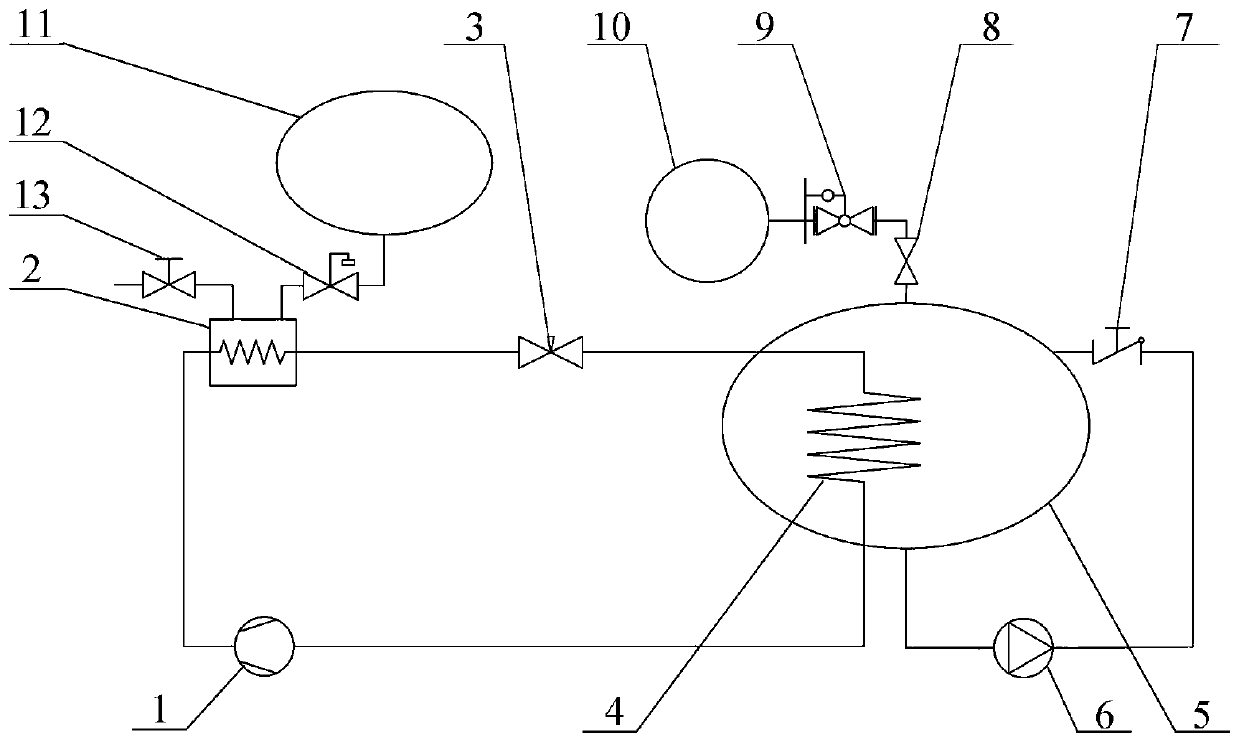

ActiveCN111503921AChange the status quo that it is impossible to prepare supercooled liquid hydrogen on a large scaleLow investment costHeat recovery systemsCompression machinesSpace launchCirculator pump

The invention discloses a liquid hydrogen supercooling degree acquisition system for a space launching site. The system involves a liquid hydrogen storage tank, wherein a top pressurization opening ofthe liquid hydrogen storage tank is connected with an outlet of a high-pressure helium tank through a valve; a bottom outlet of the liquid hydrogen storage tank is connected with a liquid hydrogen side inlet of a helium-hydrogen heat exchanger through a circulating pump, and a liquid hydrogen side outlet of the helium-hydrogen heat exchanger is connected with a top reflux inlet of the liquid hydrogen storage tank through a reflux check valve; a helium side outlet of the helium-hydrogen heat exchanger is connected with a helium side inlet of a liquid hydrogen bath-type heat exchanger through acold helium compressor, and a helium side outlet of the liquid hydrogen bath-type heat exchanger is connected with a helium side inlet of the helium-hydrogen heat exchanger through a throttling valve; and a liquid hydrogen inlet of the liquid hydrogen bath-type heat exchanger is connected with the bottom outlet of the liquid hydrogen storage tank through a float regulating valve, and a hydrogen outlet of the liquid hydrogen bath-type heat exchanger is emptied through a hydrogen discharge valve. According to the system, a large number of liquid hydrogen cold sources existing in the launching site are used for precooling, and large-scale on-site preparation of the launching site with the large supercooling degree of liquid hydrogen can be achieved in combination with the cold helium compressor; and the equipment investment and transformation cost is low, and engineering implementation is easy.

Owner:XI AN JIAOTONG UNIV

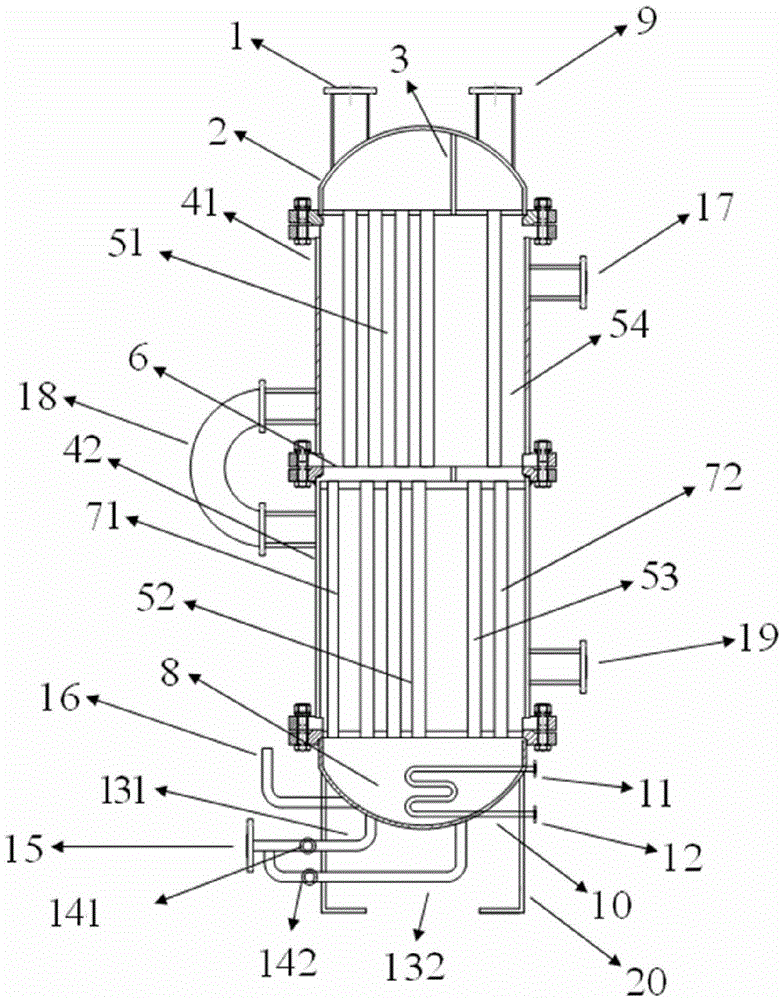

Tubular condensation heat exchanger and heat exchange method thereof

ActiveCN104457309APrevent re-vaporizationIncrease the scope of applicationSteam/vapor condensersCooling UnitsEngineering

The invention provides a tubular condensation heat exchanger and a heat exchange method thereof. The condensation heat exchanger comprises a condenser body, a pipe-in cooling unit and a supercooling unit, wherein the condenser body comprises a tube body unit, a first seal head and a second seal head, the first seal head and the second seal head are arranged on both sides of the tube body, a steam inlet is formed in the first seal head, and the tube body unit comprises a first tube body, a second tube body and a third tube body; the first tube body is separated from the second tube body through a first gas-liquid separator, and the second tube body is separated from the third tube body through a second gas-liquid separator; the pipe-in cooling unit is arranged in the tube body unit, and the supercooling unit is arranged on the second seal head. The tubular condensation heat exchanger disclosed by the invention effectively uses a heat exchange area, quickly drains condensate, avoids the phenomena that the condensate is accumulated and two-phase flows are generated, and obviously increases the heat transfer coefficient.

Owner:福建蓝海节能科技有限公司

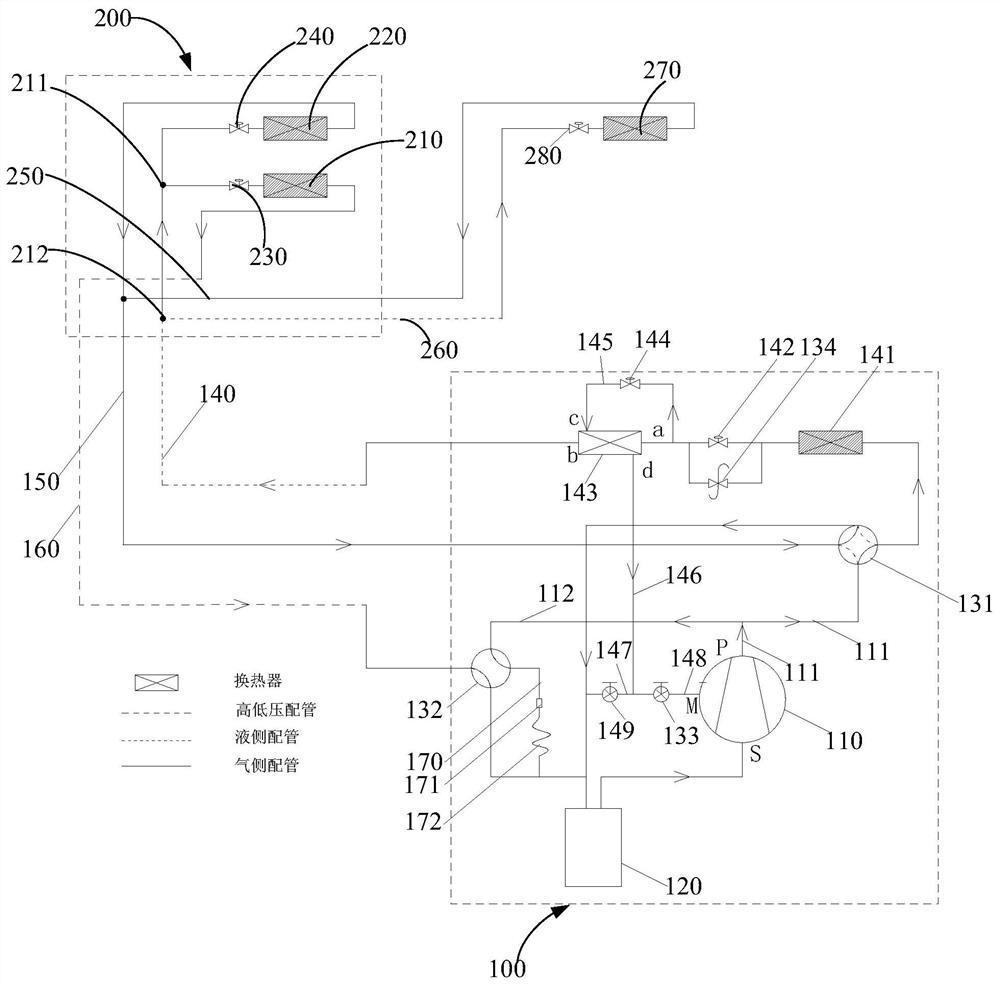

Control method of air conditioner

PendingCN112013473AGuaranteed cooling effectLarge openingMechanical apparatusFluid circulation arrangementEngineeringRefrigeration

The invention discloses a control method of an air conditioner. The control method of the air conditioner comprises the following steps of obtaining the refrigeration superheat degree of the refrigerant outflow end of a reheating heat exchanger in a refrigeration mode; comparing the refrigeration superheat degree with the refrigeration target superheat degree; if the refrigeration superheat degreeis larger than the refrigeration target superheat degree, reducing the opening degree of a reheating adjusting valve; if the refrigeration superheat degree is smaller than the refrigeration target superheat degree, increasing the opening degree of the reheating adjusting valve; and if the refrigeration superheat degree is equal to the refrigeration target superheat degree, keeping the opening degree of the reheating adjusting valve. According to the technical scheme, the refrigeration efficiency of an indoor heat exchanger in the refrigeration mode is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

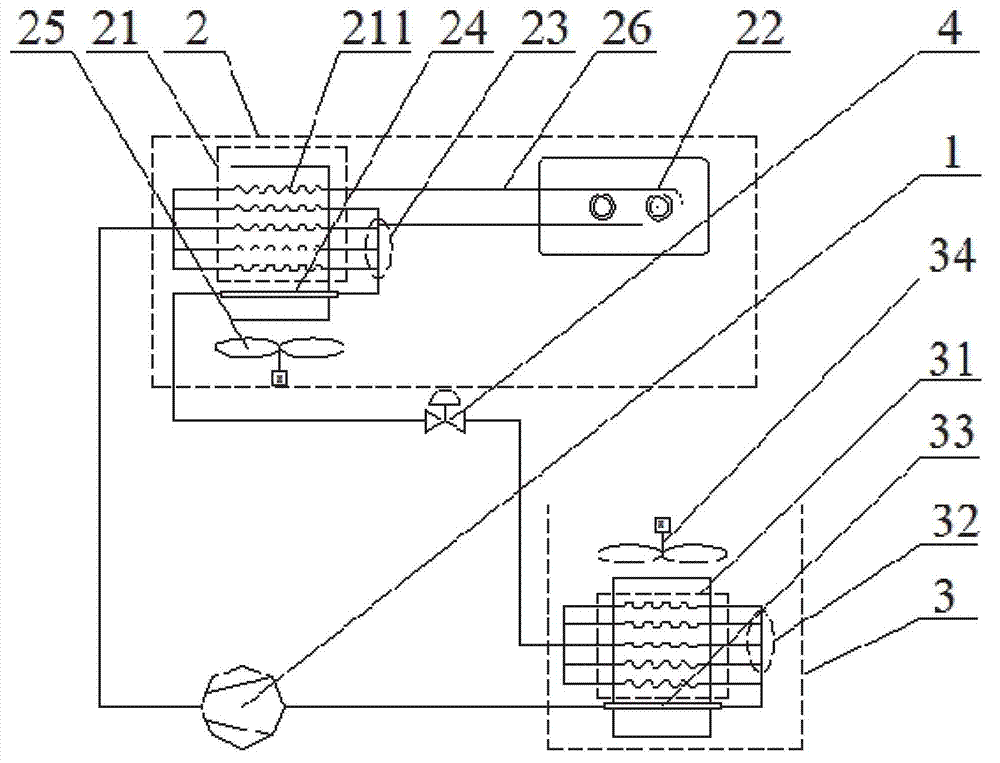

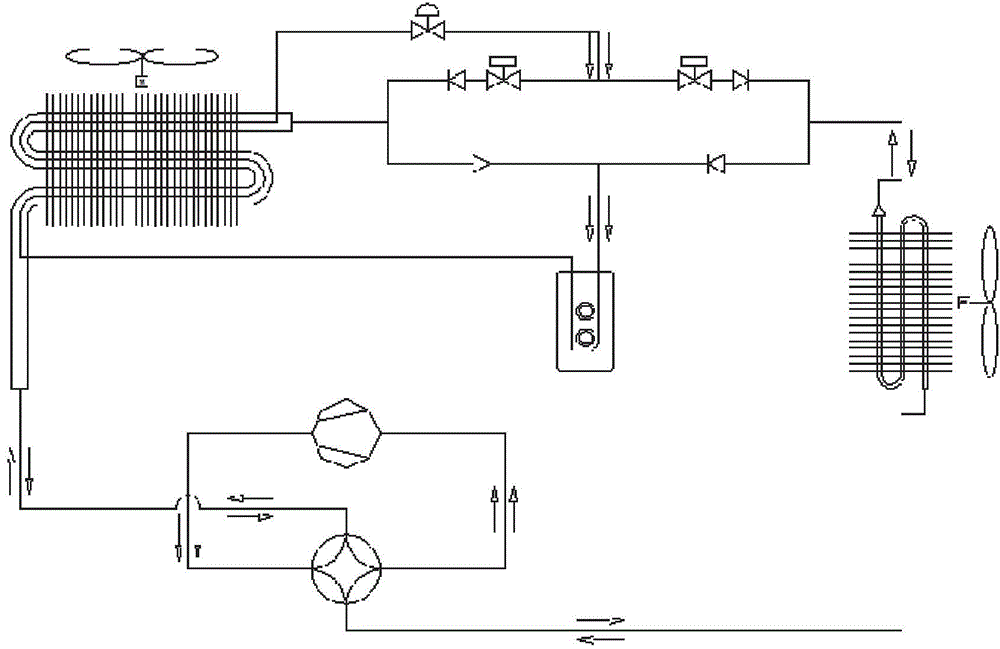

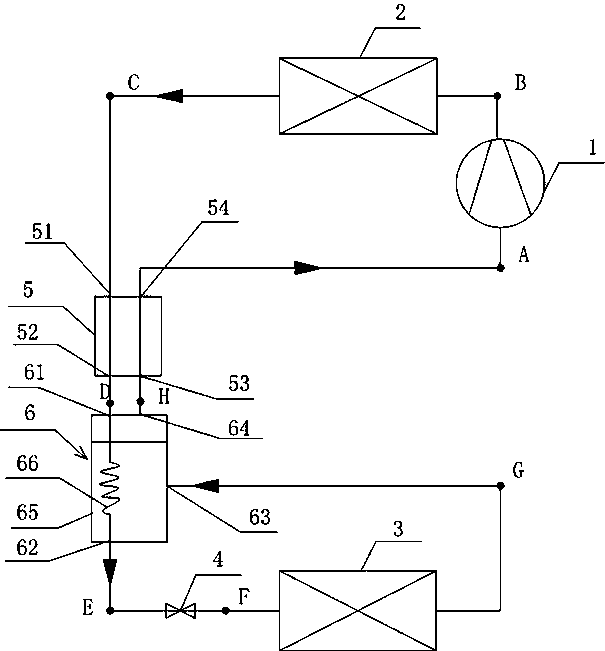

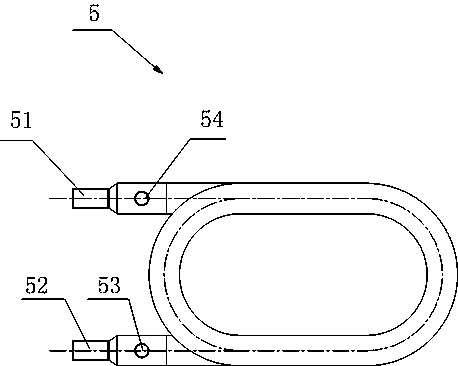

Machine room air conditioner synchronizing supercooling and superheating

ActiveCN102927677AImprove heat transfer effectIncrease cooling capacityEvaporators/condensersSpace heating and ventilation detailsPhysicsSubcooling

The invention discloses a machine room air conditioner synchronizing supercooling and superheating. The machine room air conditioner comprises a compressor, a condenser assembly, an expansion valve and an evaporator assembly which are all in sequential connection, wherein an outlet of the evaporator assembly is connected with an inlet of the compressor to form a refrigeration circulation loop. The condenser assembly comprises multiple branch condensing coils, a high-pressure liquid storage tank, a liquid collection device, a supercooling coil and a condenser fan, wherein the supercooling coil is arranged in a position with the best heat exchange effect in the condensing assembly and is parallel with the multi-branch condensing coil, an outlet of a branch condensing coil with the worst condensing effect in the multiple branch condensing coils is connected with an inlet of the high-pressure liquid storage tank, an outlet of the high-pressure liquid storage tank and outlets of other branch condensing coils are together connected with an inlet of the liquid collection device, and an outlet of the liquid collection device is connected with an inlet of the expansion valve though the supercooling coil. The machine room air conditioner effectively resolves the problems of loss of the obtained degree of the supercooling, avoids wet compression of the compressor, and can improve refrigeration performance and working stability of the machine room air conditioner.

Owner:NANJING NORMAL UNIVERSITY

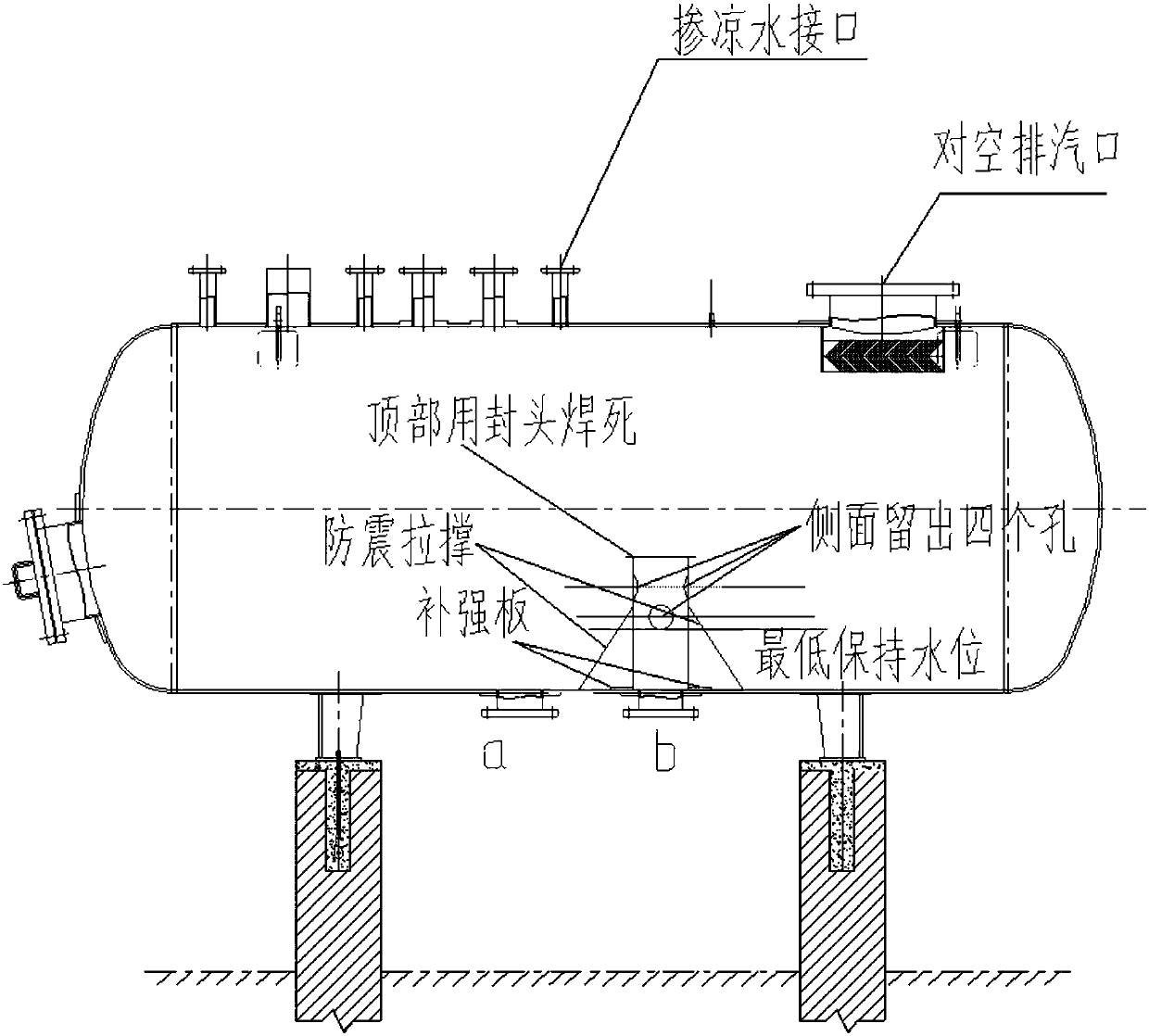

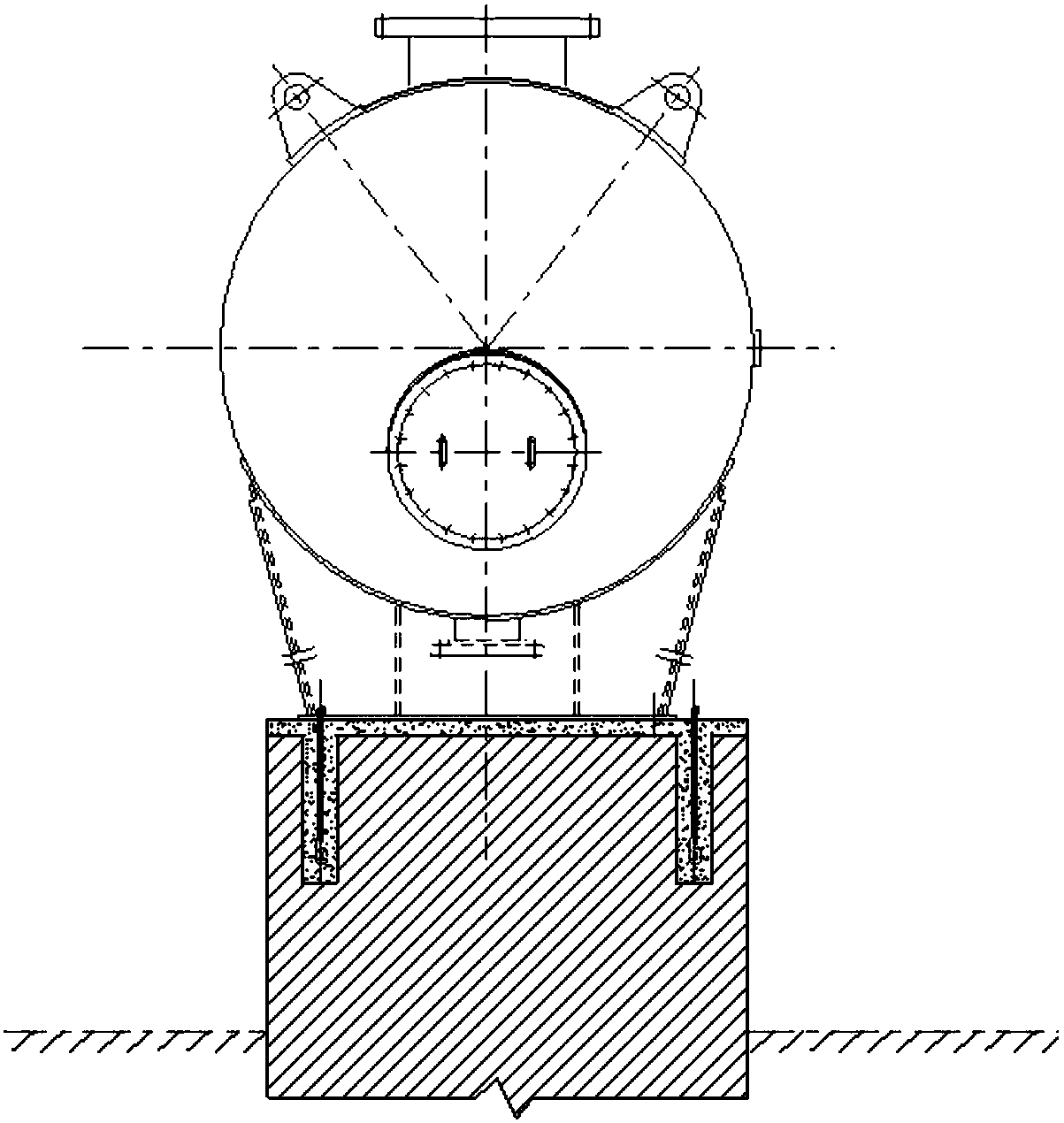

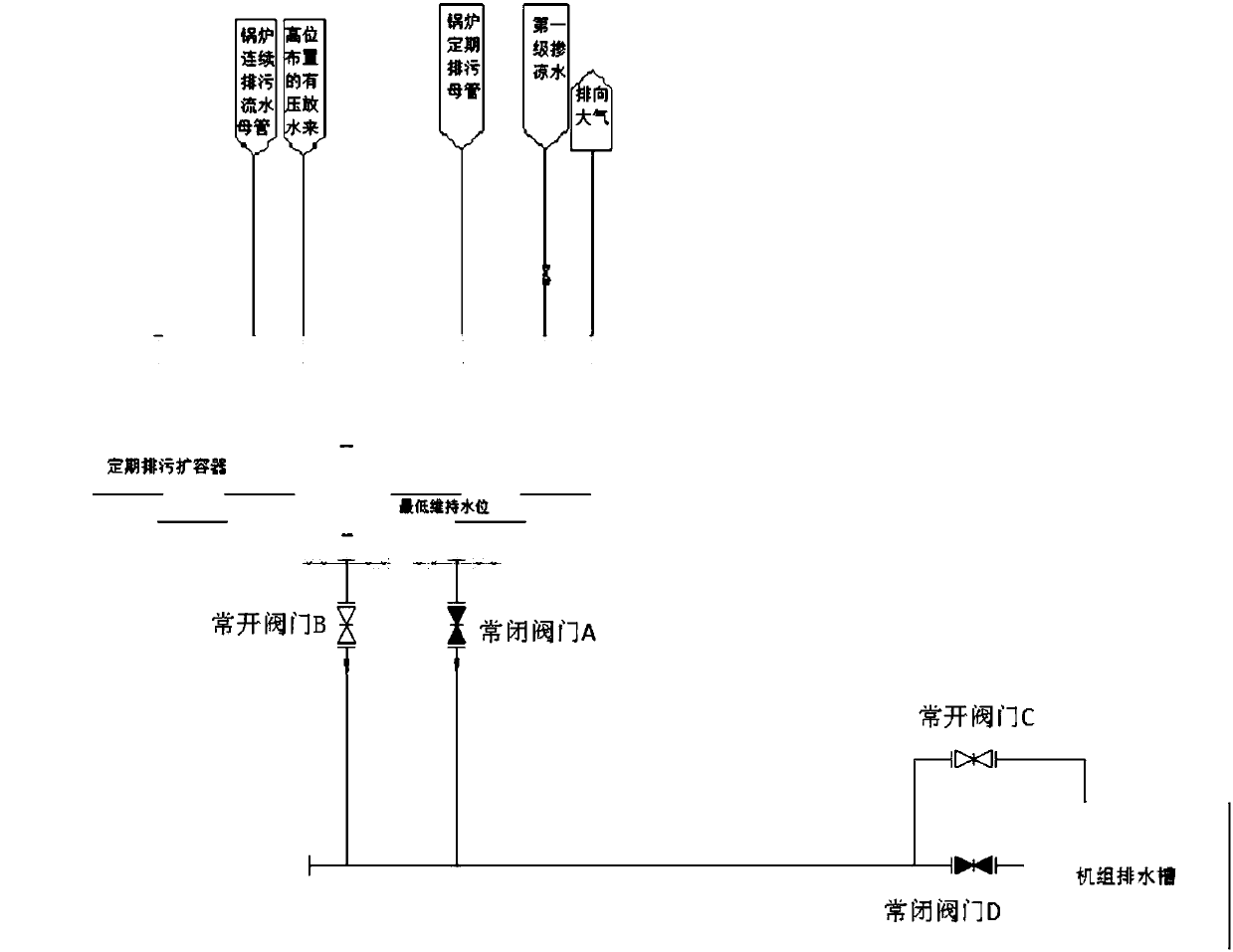

Intermittent blowdown flash tank with self water sealing function and drainage system and method

The invention discloses an intermittent blowdown flash tank with a self water sealing function and a drainage system and method. The intermittent blowdown flash tank with the self water sealing function comprises an intermittent blowdown flash tank body, at least two drainage outlets are formed in the bottom of the intermittent blowdown flash tank body, a flow guiding pipe communicating with one drainage outlet is arranged in the intermittent blowdown flash tank body, and the height of the flow guiding pipe is higher than the lowest maintaining water level of the intermittent blowdown flash tank. A flow guiding hole is formed in the part, above the lowest maintaining water level of the intermittent blowdown flash tank, of the pipe wall of the flow guiding pipe, and the formed position of the flow guiding hole can ensure that the water stored in the intermittent blowdown flash tank can be always maintained at a lowest water level. The intermittent blowdown flash tank has the beneficialeffects that the system is greatly simplified and optimized, backflow of a corrosive medium in a drainage tank is prevented, and thus the safety of a machine unit is improved. The intermittent blowdown flash tank with the self water sealing function and the drainage system are particularly suitable for design of drainage systems for starting intermittent blowdown flash tanks of boilers, small machine units and gas turbine waste heat boilers.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

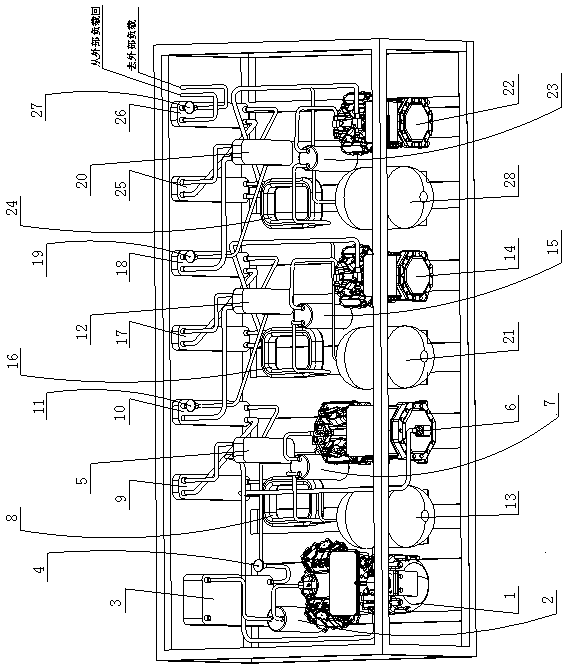

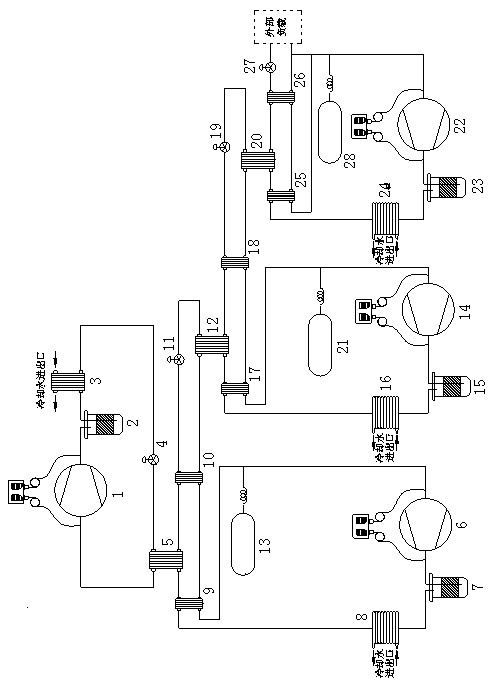

Four-stage cascade refrigerating device with multi-stage water cooler

PendingCN110953741AEasy accessImprove cooling effectSubcoolersCompression machines with cascade operationProcess engineeringRefrigeration

The invention relates to the field of cascade refrigeration, and provides a four-stage cascade refrigerating device with a multi-stage water cooler. The four-stage cascade refrigerating device cascades by four pieces of relatively independent refrigerating circulation. A water cooler is independently arranged on a second-stage compressor high-temperature gas exhaust pipeline, a third-stage compressor high-temperature gas exhaust pipeline and a fourth-level compressor high-temperature gas exhaust pipeline of the cascade refrigerating circulation, cheap cooling water which can be easily obtainedand is out of a system is introduced, and therefore, a refrigeration quantity and refrigeration efficiency can be effectively improved. Meanwhile, a precooling heat regenerator and an undercooling heat regenerator are configured in a second-stage high-temperature pipeline, a third-stage high-temperature pipeline and a fourth-stage high-temperature pipeline of the cascade refrigerating circulation, so that refrigeration efficiency can be improved, and the safe operation of a compressor can be guaranteed.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

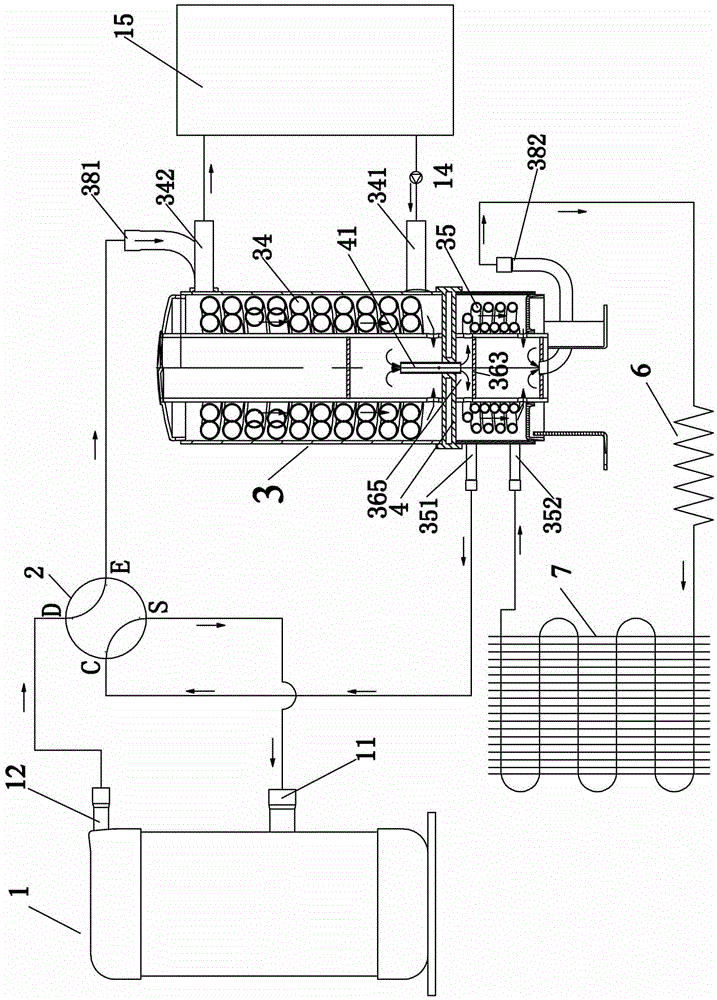

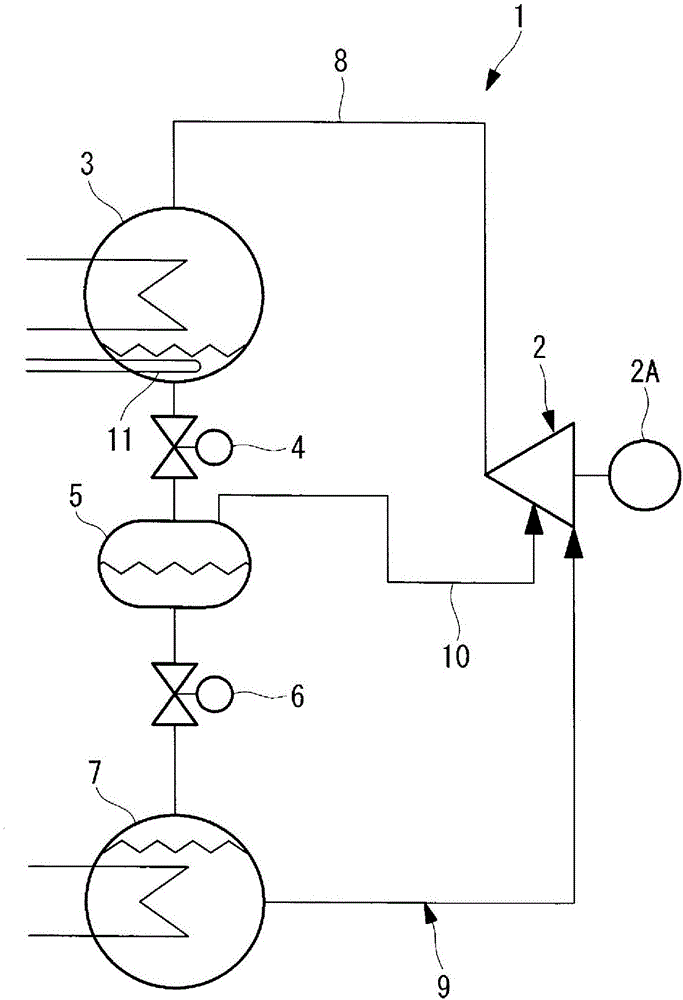

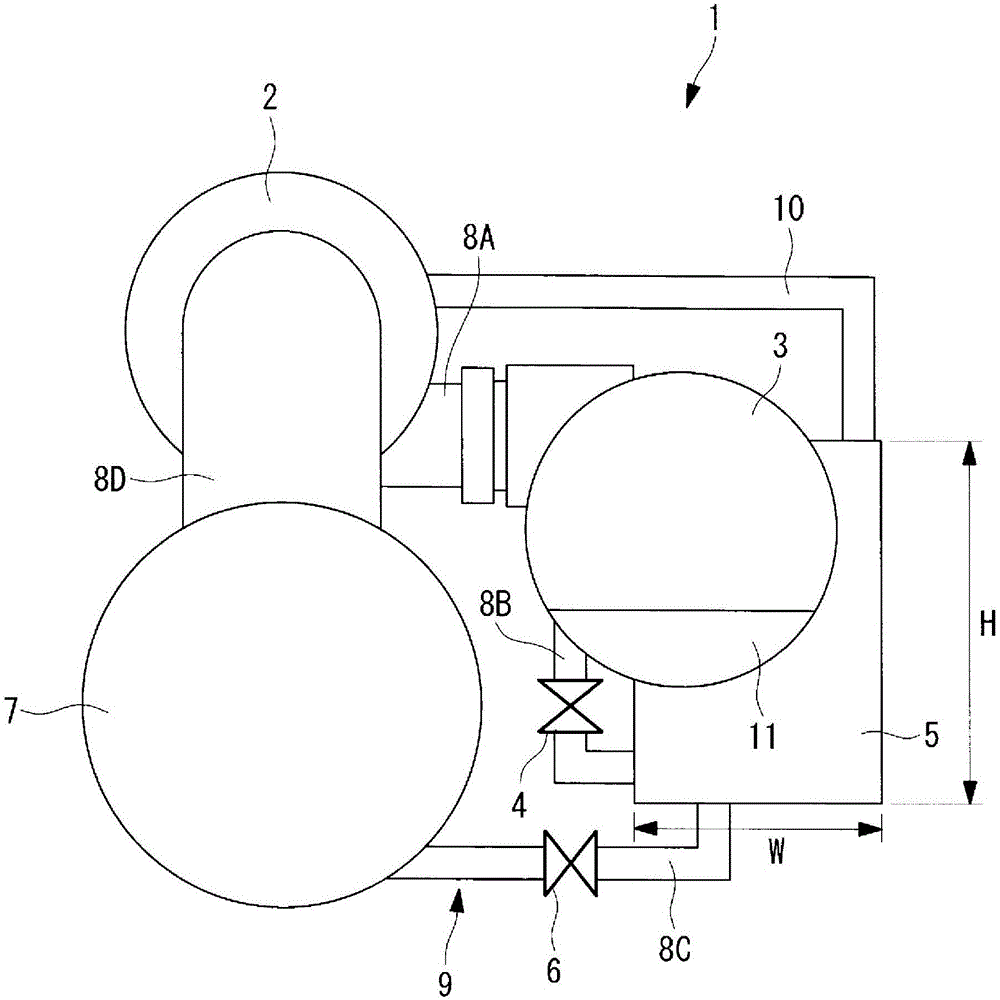

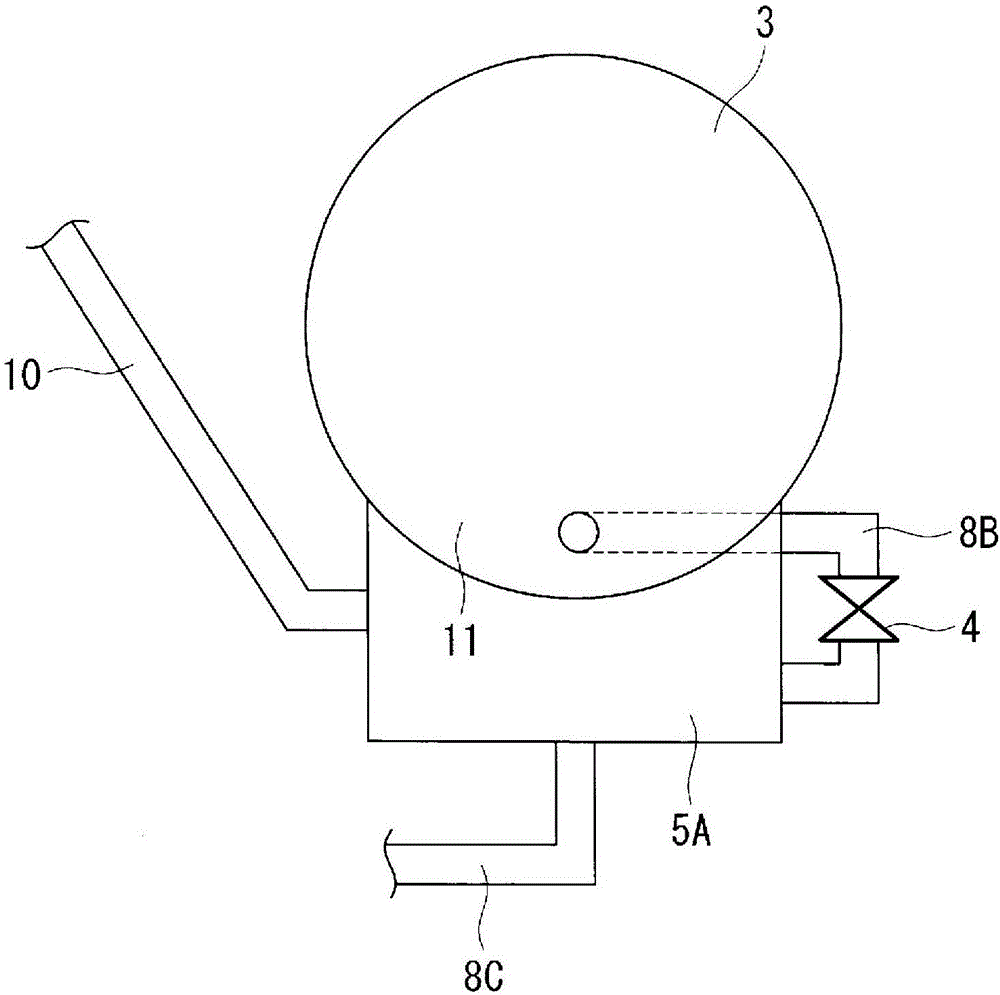

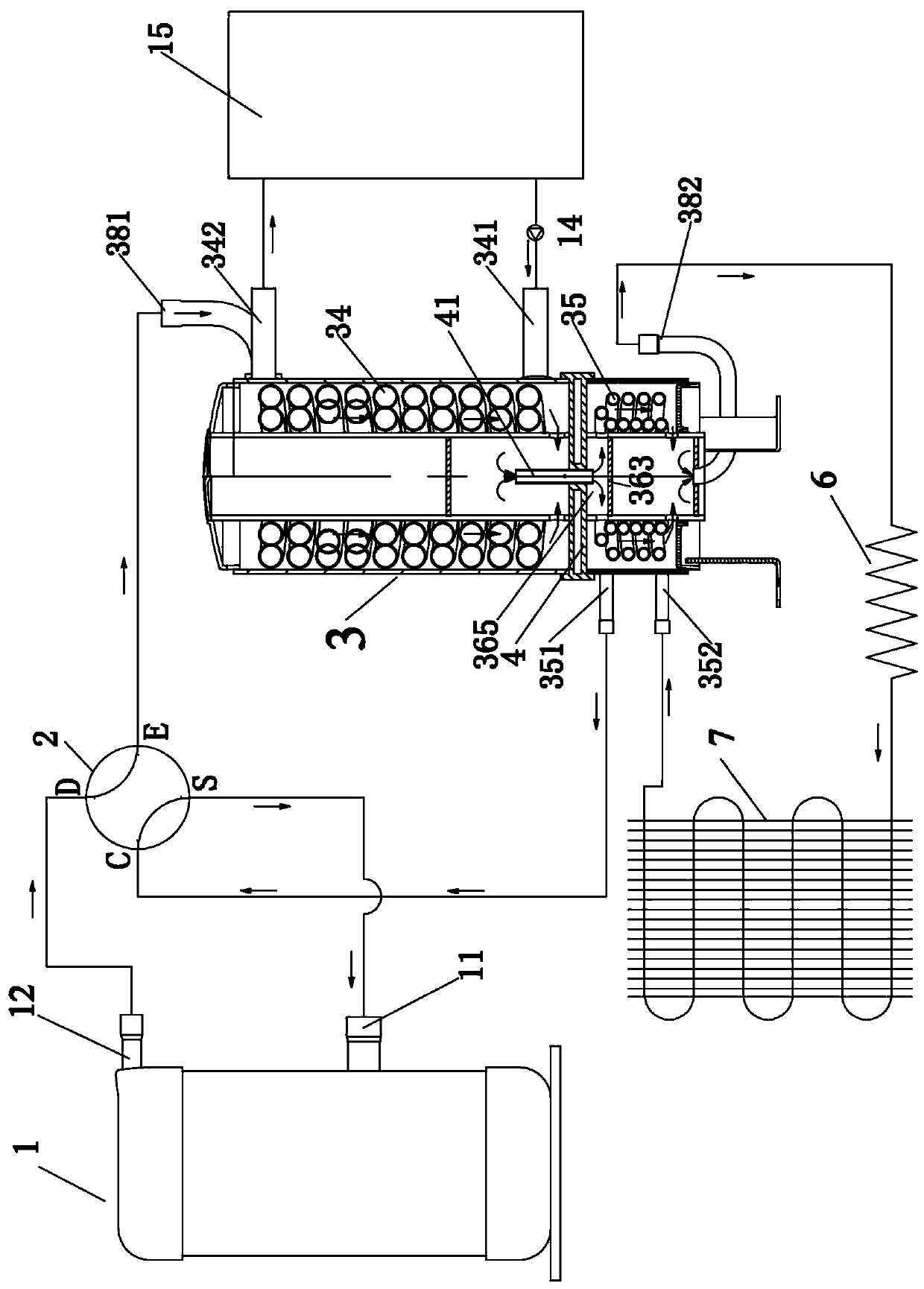

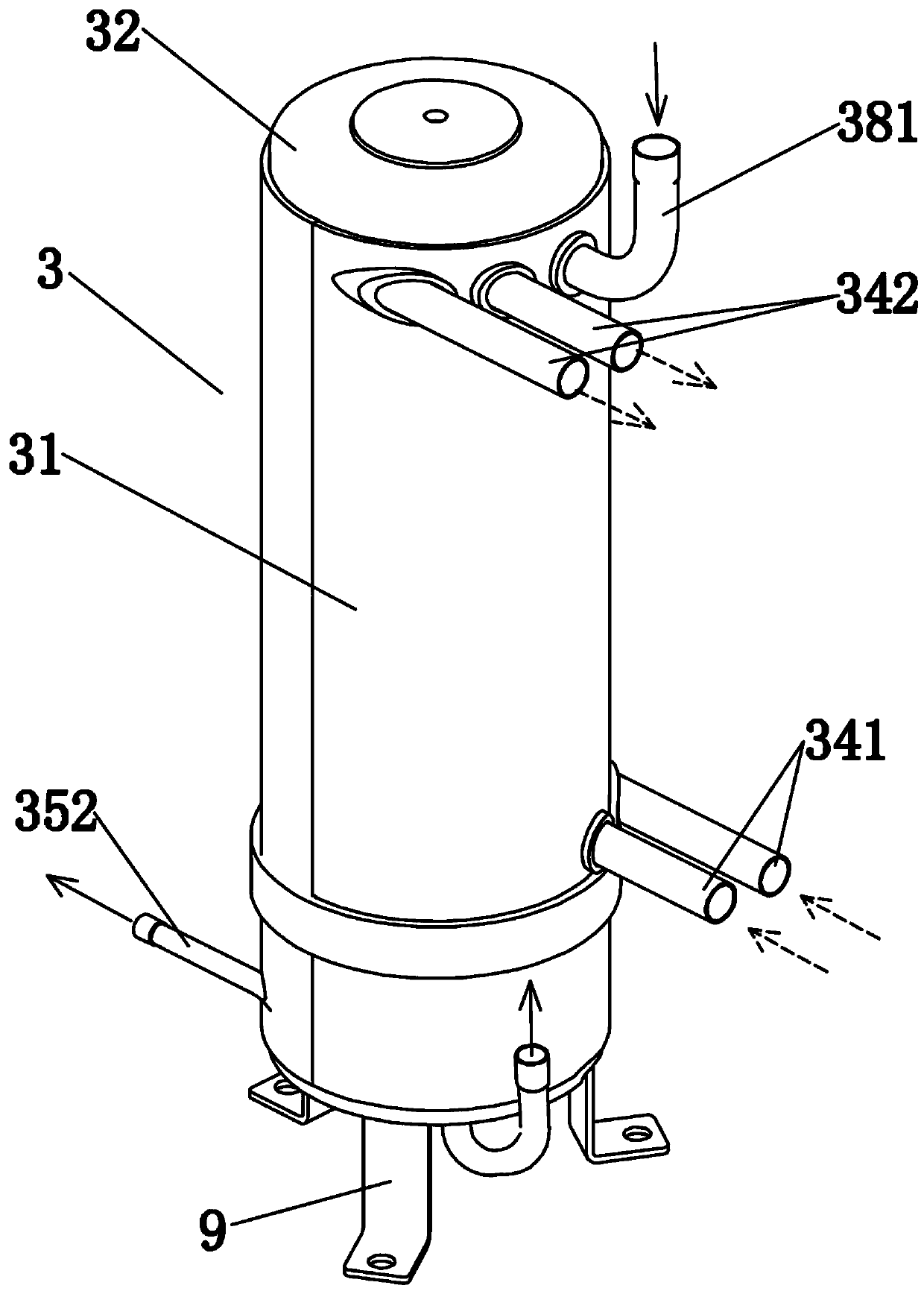

Turbo refrigeration machine

ActiveCN106574811AEnsure normal flowEfficient flowMechanical apparatusCompression machines with non-reversible cycleEngineeringIntercooler

A turbo refrigeration machine (1) in which a closed-cycle refrigeration cycle (9) is formed by connecting a compressor (2), a condenser (3), an intercooler (5) and decompression means (4, 6) forming a multi-stage compression cycle, and an evaporator (7), with the refrigeration cycle (9) being charged with a low-pressure refrigerant. The condenser (3) and the intercooler (5) are integrated with each other by having a portion of their container walls form a shared wall, with the base surface of the intercooler (5) being positioned below the base surface of the condenser (3) and above the base surface of the evaporator (7).

Owner:MITSUBISHI HEAVY IND THERMAL SYST

Water chilling unit

InactiveCN113028665AReduce chargePrevent liquid shockCompression machines with non-reversible cycleEvaporators/condensersEngineeringSuperheater

The invention belongs to the technical field of water chilling units, and aims to solve the problem that a falling film evaporator adopted by an existing water chilling unit cannot remarkably reduce the refrigerant filling amount. For this aim, the provided water chilling unit comprises an evaporator, a condenser, a compressor, a subcooler and a superheater, and the condenser, the subcooler, the evaporator, the superheater and the compressor form a closed refrigerant circulation loop, the water chilling unit further comprises a first cooling water inlet pipe, a second cooling water inlet pipe, a first cooling water connecting pipe and a second cooling water connecting pipe, the first cooling water inlet pipe is connected with the condenser and the subcooler, the first cooling water connecting pipe is connected between the subcooler and the condenser, the second cooling water inlet pipe is connected with the evaporator and the superheater, and the second cooling water connecting pipe is connected between the superheater and the evaporator. According to the water chilling unit, the refrigerant filling amount of the water chilling unit can be greatly reduced, and greenhouse gas emission is remarkably reduced.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Machine room air conditioner synchronizing supercooling and superheating

ActiveCN102927677BReduce areaImprove heat transfer effectEvaporators/condensersSpace heating and ventilation detailsLiquid storage tankEngineering

The invention discloses a machine room air conditioner synchronizing supercooling and superheating. The machine room air conditioner comprises a compressor, a condenser assembly, an expansion valve and an evaporator assembly which are all in sequential connection, wherein an outlet of the evaporator assembly is connected with an inlet of the compressor to form a refrigeration circulation loop. The condenser assembly comprises multiple branch condensing coils, a high-pressure liquid storage tank, a liquid collection device, a supercooling coil and a condenser fan, wherein the supercooling coil is arranged in a position with the best heat exchange effect in the condensing assembly and is parallel with the multi-branch condensing coil, an outlet of a branch condensing coil with the worst condensing effect in the multiple branch condensing coils is connected with an inlet of the high-pressure liquid storage tank, an outlet of the high-pressure liquid storage tank and outlets of other branch condensing coils are together connected with an inlet of the liquid collection device, and an outlet of the liquid collection device is connected with an inlet of the expansion valve though the supercooling coil. The machine room air conditioner effectively resolves the problems of loss of the obtained degree of the supercooling, avoids wet compression of the compressor, and can improve refrigeration performance and working stability of the machine room air conditioner.

Owner:NANJING NORMAL UNIVERSITY

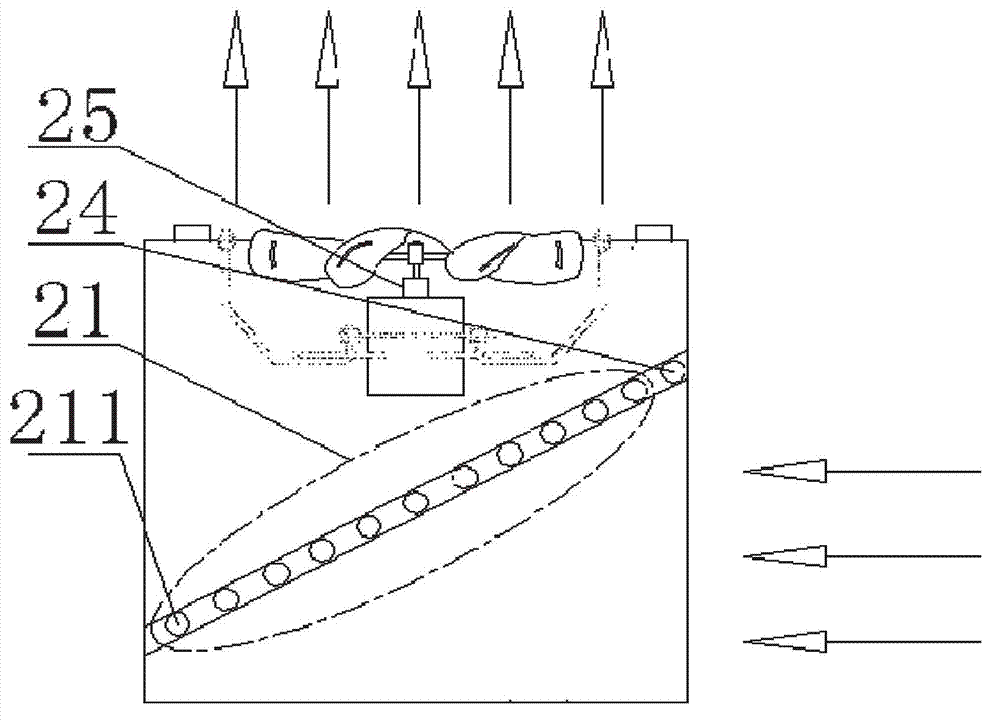

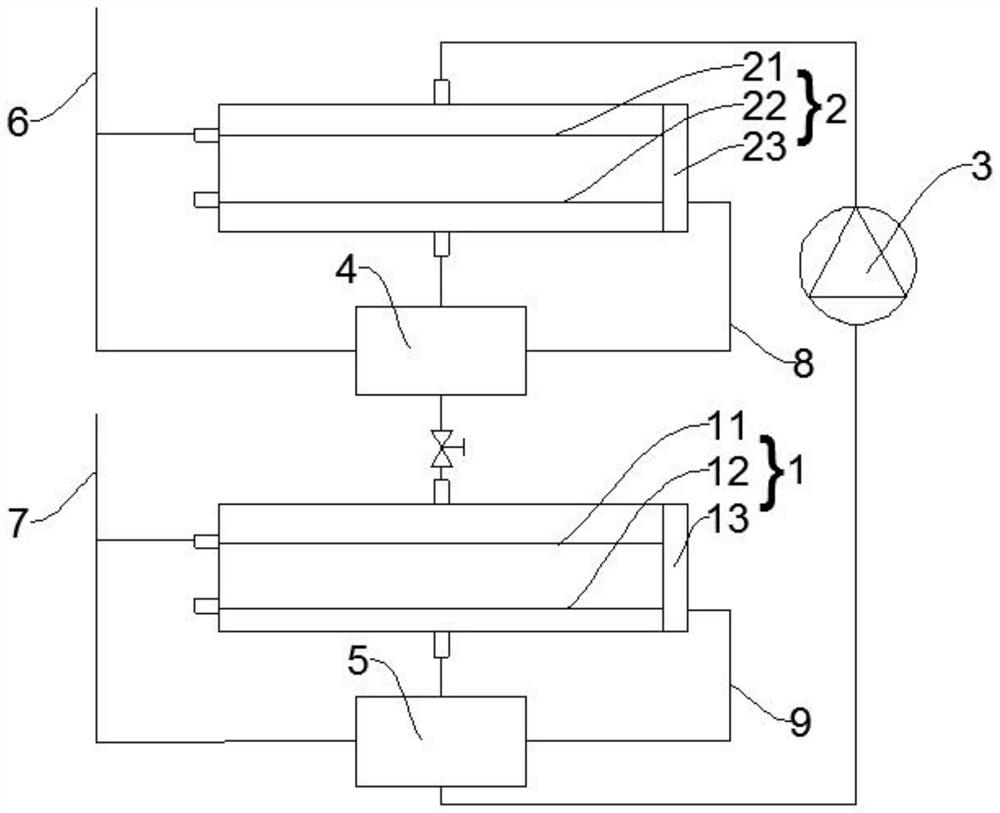

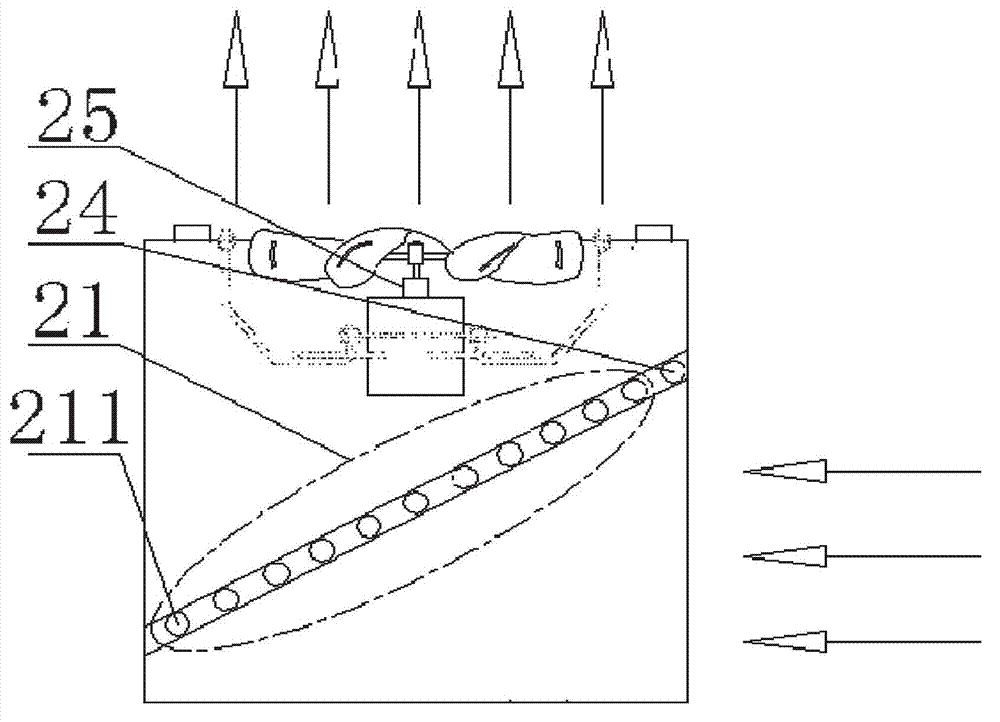

A fresh air air handling unit with synchronous subcooling and superheating

ActiveCN102927628BImprove heat transfer effectGuaranteed subcoolingFluid circulation arrangementHeating and refrigeration combinationsFresh airAir treatment

The invention discloses a full-fresh-air air handling unit capable of overcooling and overheating synchronously. The full-fresh-air air handling unit comprises a compressor, a four-way reversing valve, an outdoor handling unit heat exchanger, a bi-directional expansion valve and an indoor air supply unit heat exchanger. An air inlet end and an air outlet end of the compressor are connected with two opposite connectors on the four-way reversing valve respectively, a refrigeration inlet of the outdoor handling unit heat exchanger and a refrigeration outlet of the indoor air supply unit heat exchanger are connected with the other two opposite connectors on the four-way reversing valve respectively, and a refrigeration outlet of the outdoor handling unit heat exchanger is connected with a refrigeration inlet of the indoor air supply unit heat exchanger through the bi-bidirectional expansion valve. The full-fresh-air air handling unit effectively solves the problem of loss of obtained overcooling degree, improves the stability and reliability of working of the expansion valve, avoids wet compression of the compressor, can improve safety and reliability of the unit, and increases working energy efficiency ratio.

Owner:NANJING NORMAL UNIVERSITY

A system for obtaining liquid hydrogen subcooling degree at space launch site

ActiveCN111503921BChange the status quo that it is impossible to prepare supercooled liquid hydrogen on a large scaleLow investment costHeat recovery systemsCompression machinesSpace launchEngineering

A liquid hydrogen subcooling degree acquisition system for an aerospace launch site, comprising a liquid hydrogen storage tank, the top pressure booster port of the liquid hydrogen storage tank is connected to the outlet of a high-pressure helium cylinder through a valve; the bottom outlet of the liquid hydrogen storage tank is connected to helium- The liquid hydrogen side inlet of the hydrogen heat exchanger and the liquid hydrogen side outlet of the helium-hydrogen heat exchanger are connected to the return port at the top of the liquid hydrogen storage tank through a return check valve; the helium gas side outlet of the helium-hydrogen heat exchanger is compressed by cold helium The machine is connected to the helium side inlet of the liquid hydrogen bath heat exchanger, and the helium side outlet of the liquid hydrogen bath heat exchanger is connected to the helium side inlet of the helium-hydrogen heat exchanger through a throttle valve; the liquid hydrogen bath heat exchanger The liquid hydrogen inlet is connected to the bottom outlet of the liquid hydrogen storage tank through a float regulating valve, and the hydrogen outlet of the liquid hydrogen bath heat exchanger is evacuated through a hydrogen drain valve; the present invention utilizes a large number of liquid hydrogen cold sources in the launch site to implement pre-cooling , Combined with the cold helium compressor, it can realize the large-scale on-site preparation of liquid hydrogen with large subcooling degree; the equipment investment and transformation cost are low, and it is easy to realize engineering.

Owner:XI AN JIAOTONG UNIV

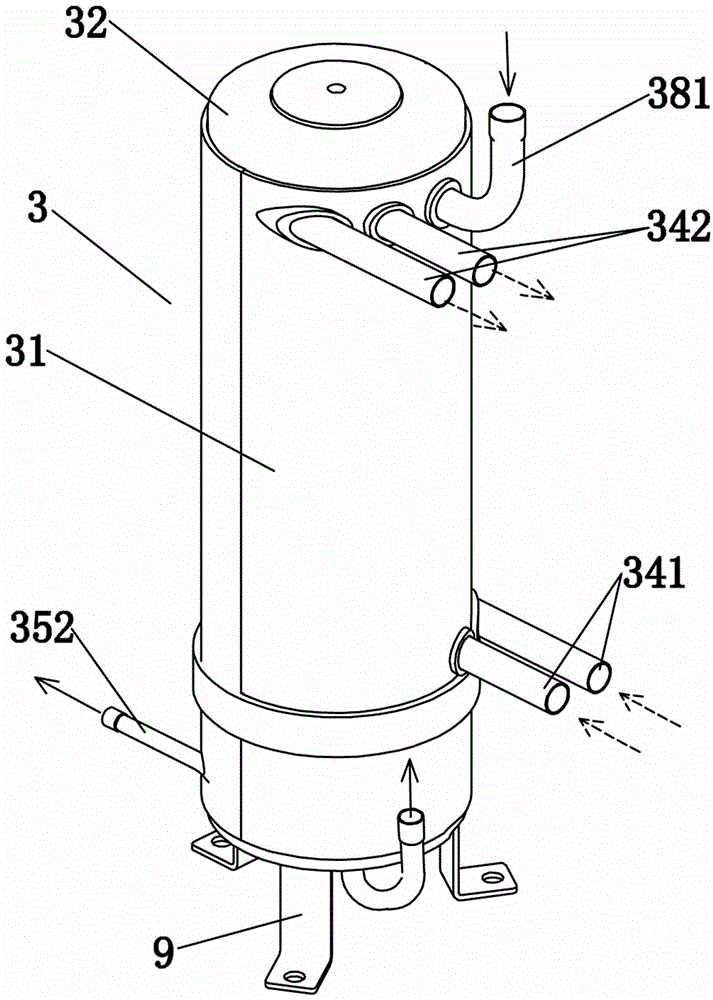

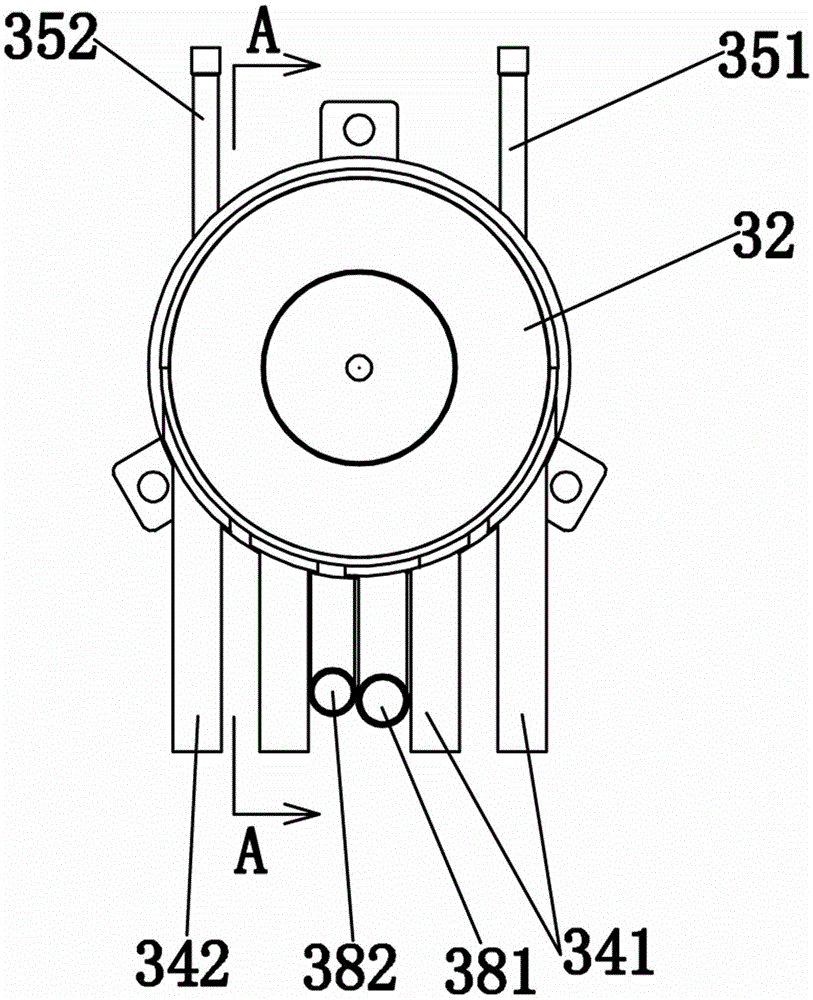

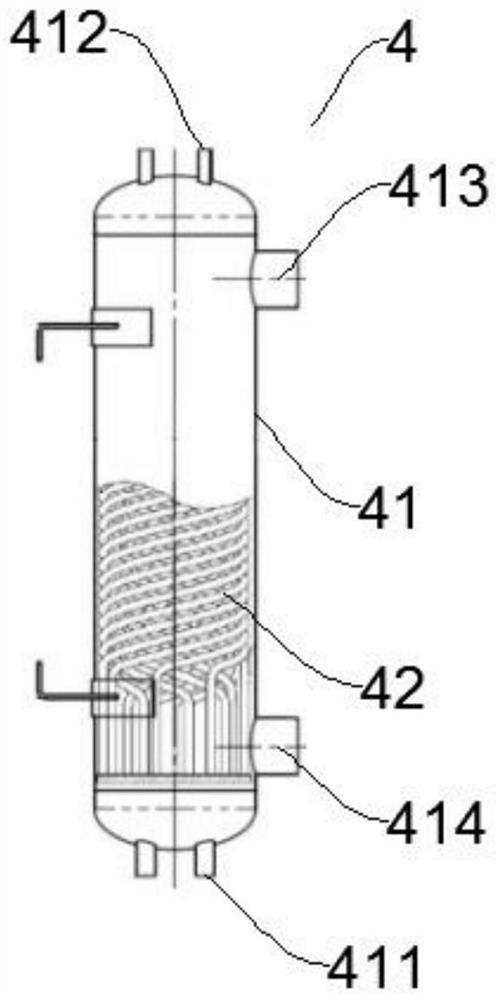

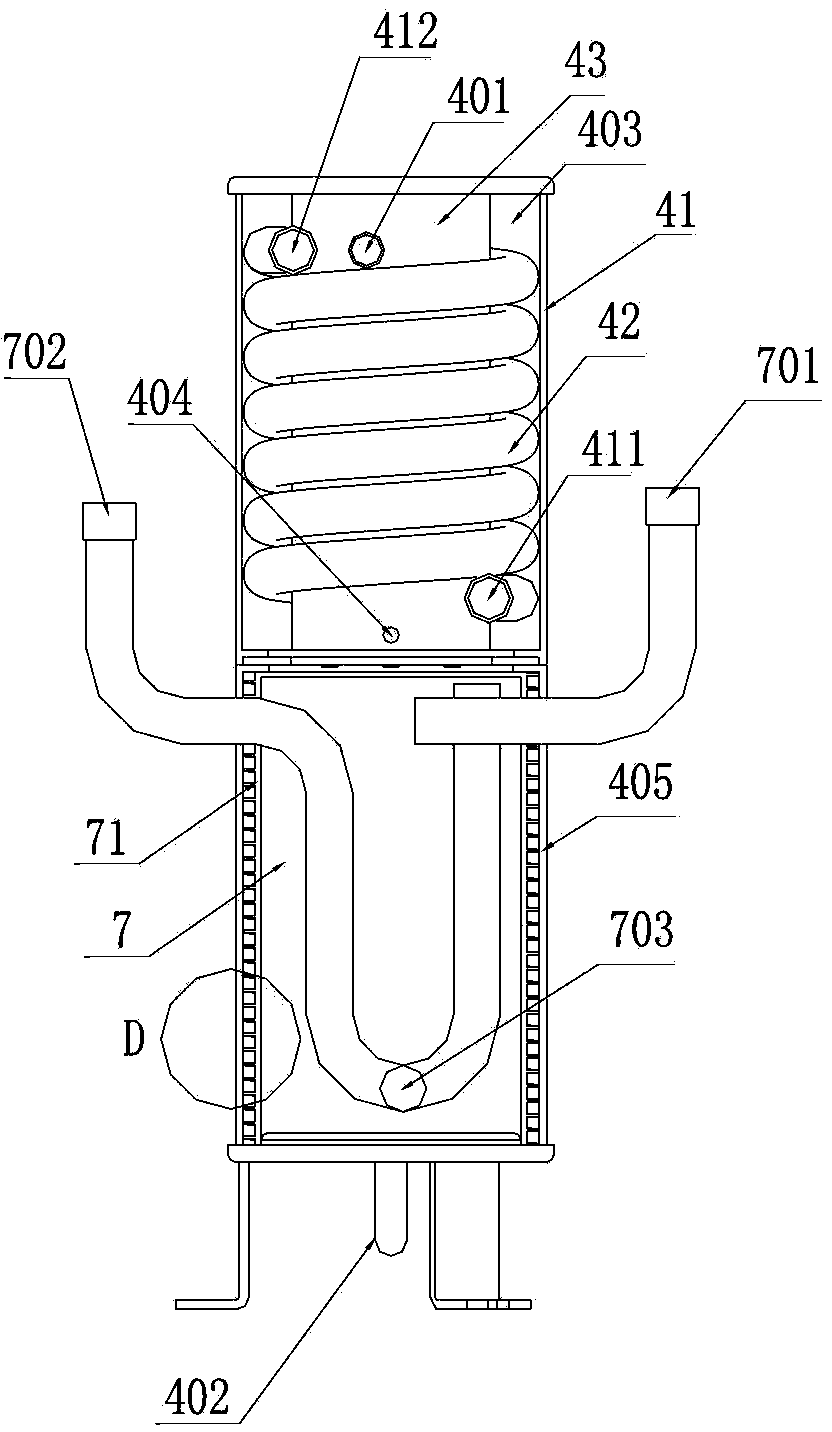

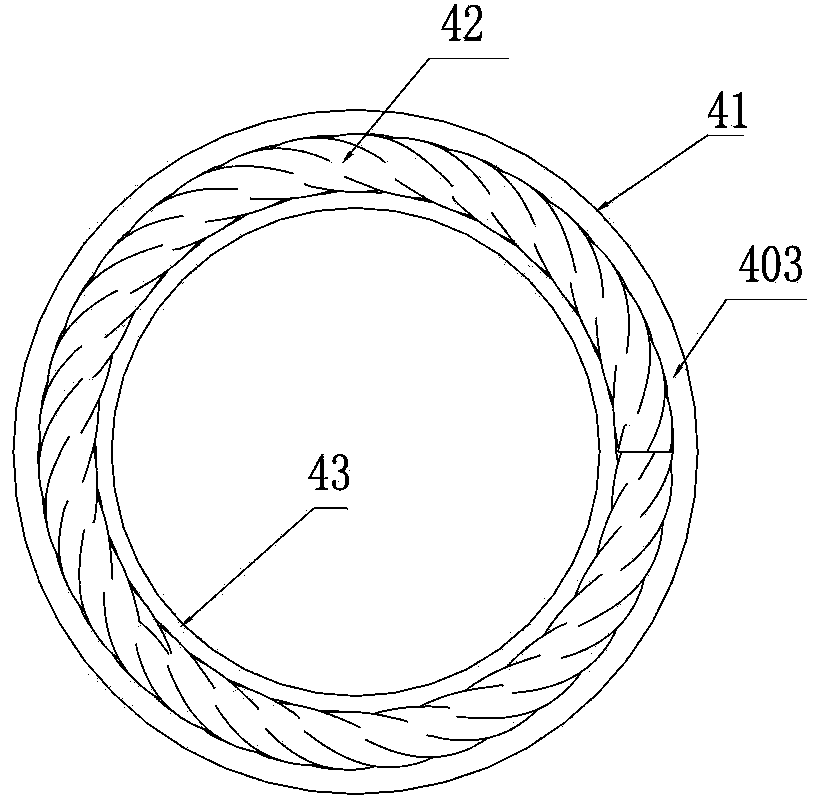

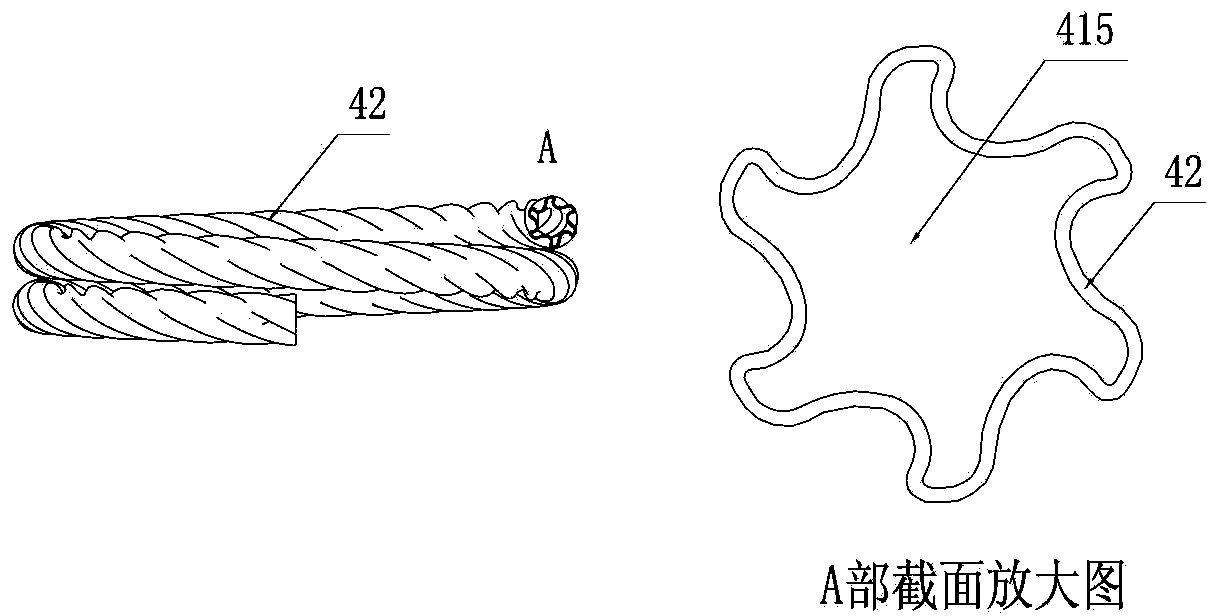

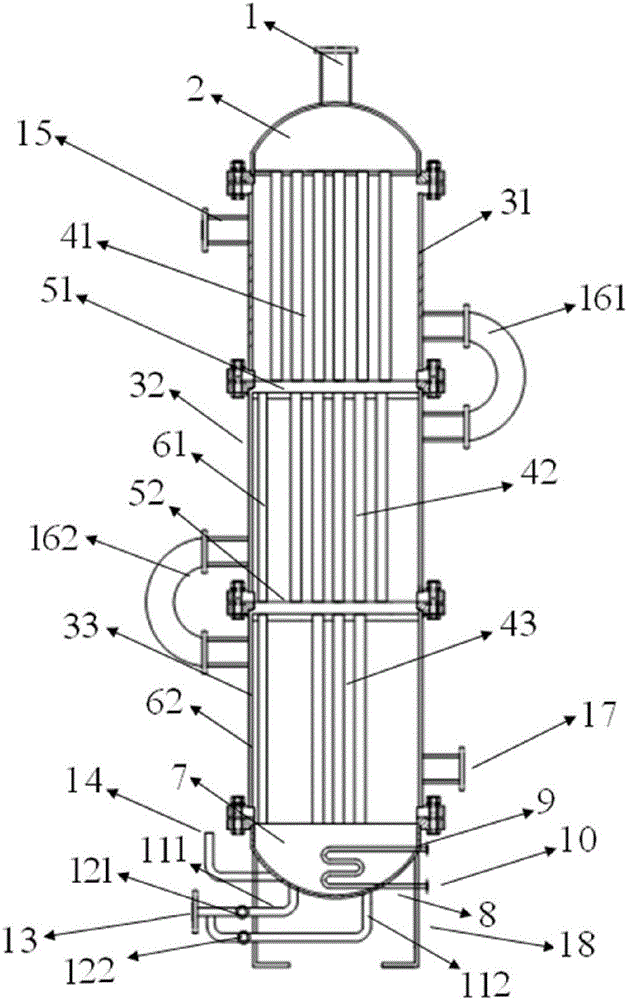

Heat utilization balance processor

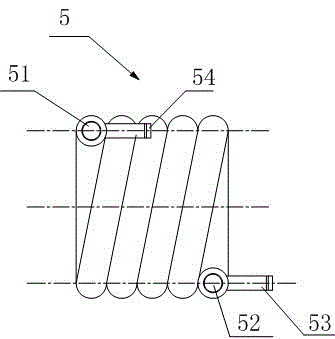

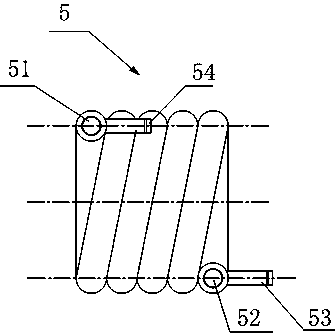

ActiveCN102798254BImprove energy efficiencyGuaranteed uptimeEvaporators/condensersCondensation processVapor–liquid separator

A heat utilization balance processor relates to a heat exchanger unit for a heat pump hot water machine or a refrigerating cycle system, and in particular relates to a heat utilization balance processor which is suitable for R407C environment-friendly refrigerant. A heat exchange tube is coiled into a spiral shape and arranged in a main heat exchanging cavity; a vapor separation barrel of a vapor-liquid separator is arranged at the lower half part in a shell; an auxiliary heat exchanging cavity is formed between the lower half part of the shell and the outer periphery of the vapor separation barrel; the upper part of the main heat exchanging cavity is communicated to a working medium inlet outside the shell; the main heat exchanging cavity is communicated with the auxiliary heat exchanging cavity through a working medium passage hole; the bottom of the auxiliary heat exchanging cavity is communicated to a working medium outlet outside the shell; and a heat medium water passage is arranged inside the heat exchanging pipe. Through heat utilization balance exchange on the working medium in the process of condensation and evaporation in the auxiliary heat exchanging cavity, the problem of unbalanced phase change process caused by phase change non-isothermal characteristic of non-azeotropic mixing working medium R407C is solved, and the influence of the temperature slippage of the mixed refrigerant on the operation performance and safety of the equipment is eliminated.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

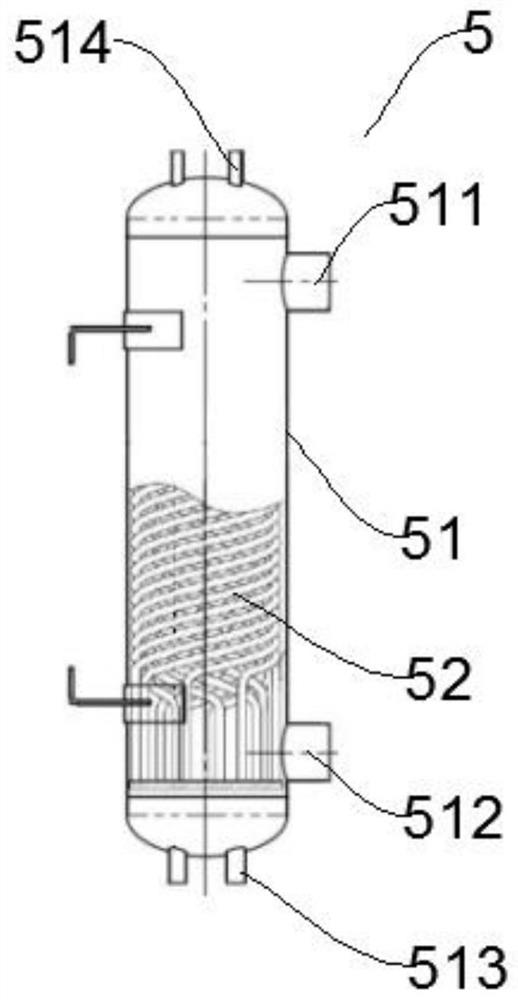

A refrigerator refrigeration cycle system

ActiveCN105865064BImprove fill rateImprove heat transfer coefficientMechanical apparatusCompression machines with non-reversible cycleCondenser (heat transfer)Capillary Tubing

The invention provides a refrigeration cycle system for a freezer, including a compressor, a condenser, an evaporator, and a capillary tube. Inlet and outlet of high-pressure refrigerant and inlet and outlet of low-pressure refrigerant. The supercooled liquid receiver is equipped with inlet and outlet of supercooled refrigerant liquid, inlet and outlet of two-phase refrigerant, and outlet of saturated refrigerant vapor; the outlet of the condenser is connected to the high pressure of the regenerator. The refrigerant inlet and the high-pressure refrigerant outlet are connected to the supercooled liquid receiver. There is a supercooled refrigerant liquid inlet, and the high-pressure refrigerant outlet is connected to the evaporator inlet through a capillary tube; the evaporator outlet is connected to the two-phase refrigerant inlet, and the saturated refrigerant vapor outlet is connected The low-pressure refrigerant inlet and the low-pressure refrigerant outlet are connected to the compressor. The invention can ensure that the evaporator performs two-phase heat exchange in the whole evaporation process, significantly increases the heat transfer coefficient of the evaporator, and improves the heat exchange effect.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Aluminum alloy material, aluminum alloy hollow pipe and preparation method of aluminum alloy hollow pipe

PendingCN114277290AReduce traditional extrusionReduce stabilityFoundry mouldsFoundry coresMachiningHeating system

The invention belongs to the technical field of aluminum alloy pipe machining, and discloses an aluminum alloy material, an aluminum alloy hollow pipe and a preparation method of the aluminum alloy hollow pipe. The aluminum alloy material comprises the following components: 2.0 to 2.5 percent of Mg, 0.1 to 0.5 percent of Mn, 0.01 to 0.05 percent of Ti, 0.15 to 0.25 percent of Si, less than or equal to 0.2 percent of Fe and the balance of Al. The aluminum alloy hollow pipe is prepared in a continuous casting mode, traditional extrusion and stabilizing annealing steps are reduced, the mechanical property of the prepared pipe meets the use requirement, and the productivity is improved; and the heating system and the casting system adopt forced heating and forced cooling systems, so that the temperature gradient of a solid-liquid surface is ensured, the degree of supercooling is ensured, alloy grains are refined, and compared with an aluminum alloy pipe prepared by a semi-continuous casting method, the mechanical property is improved by 10%-15%.

Owner:YANTAI NANSHAN UNIV

A kind of through-flow condensing heat exchanger and its heat exchanging method

ActiveCN104457309BAvoid too thick and worse condensation heat transferAvoid wastingSteam/vapor condensersStationary tubular conduit assembliesEngineeringMicro heat exchanger

The invention provides a tubular condensation heat exchanger and a heat exchange method thereof. The condensation heat exchanger comprises a condenser body, a pipe-in cooling unit and a supercooling unit, wherein the condenser body comprises a tube body unit, a first seal head and a second seal head, the first seal head and the second seal head are arranged on both sides of the tube body, a steam inlet is formed in the first seal head, and the tube body unit comprises a first tube body, a second tube body and a third tube body; the first tube body is separated from the second tube body through a first gas-liquid separator, and the second tube body is separated from the third tube body through a second gas-liquid separator; the pipe-in cooling unit is arranged in the tube body unit, and the supercooling unit is arranged on the second seal head. The tubular condensation heat exchanger disclosed by the invention effectively uses a heat exchange area, quickly drains condensate, avoids the phenomena that the condensate is accumulated and two-phase flows are generated, and obviously increases the heat transfer coefficient.

Owner:福建蓝海节能科技有限公司

a secondary heat exchanger

ActiveCN105546885BImprove heat transfer efficiencyGuaranteed subcoolingEvaporators/condensersPlate heat exchangerEngineering

The invention relates to a two-stage heat exchanger. According to the two-stage heat exchanger, the interior of a shell is divided into a first-stage heat exchange cavity and a second-stage heat exchange cavity through a partition plate, the first-stage heat exchange cavity communicates with the second-stage heat exchange cavity through a communicating channel on the partition plate, a first-stage heat exchange pipe is arranged in the first-stage heat exchange cavity, and a second-stage heat exchange pipe is arranged in the second-stage heat exchange cavity. When the two-stage heat exchanger is used as a condenser and the supercooling degree of the first-stage heat exchange pipe is small, the second-stage heat exchange pipe can be put into use together; firstly, superheated refrigerant steam in the first-stage heat exchange cavity rapidly exchanges heat with cooling liquid in the first-stage heat exchange pipe and then is condensed into liquid refrigerant; then, the liquid refrigerant enters the second-stage heat exchange cavity, the liquid refrigerant in the second-stage heat exchange pipe is evaporated or saturated refrigerant steam absorbs heat of the liquid refrigerant, and therefore the refrigerant in the second-stage heat exchanger can be sufficiently supercooled before throttling, the supercooling degree of a refrigerant system is kept, the pressure of the refrigerant system and loads on a compressor are reduced, and overall energy efficiency of a unit can be improved.

Owner:FOSHAN GUANGTENG NEW ENERGY CO LTD

A device for refining grain structure

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

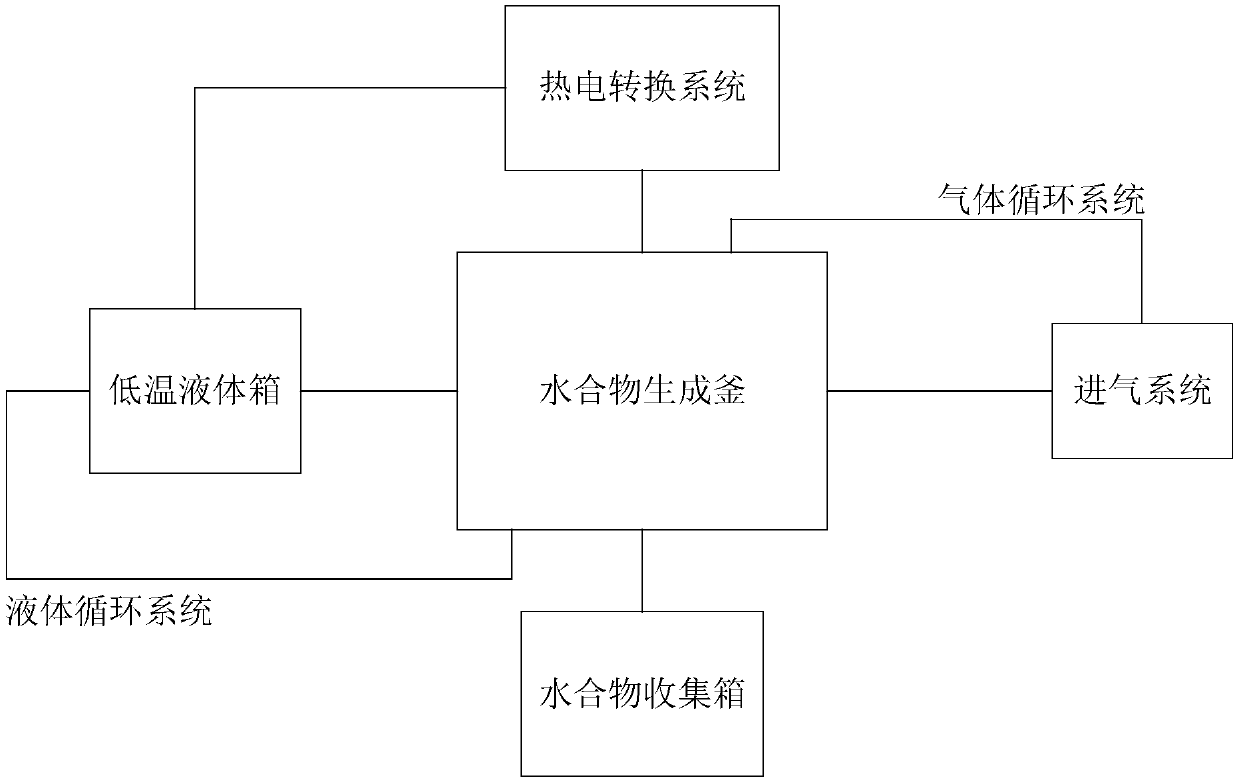

Thermoelectric effect based low energy consumption gas hydrate synthesizer

ActiveCN107837766AGuaranteed subcoolingImprove production efficiencyChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processThermal energyCollection system

The invention belongs to the technical field of hydrate application and provides a thermoelectric effect based low energy consumption gas hydrate synthesizer which comprises a thermoelectric conversion system, a hydrate synthesis kettle, a hydrate collection system, a liquid circulation system, a gas circulation system and a control system; high-pressure gas and low-temperature liquid produce hydrates in the hydrate synthesis kettle; and by utilizing the characteristic of the hydrate with the density smaller than that of water, the hydrates gather at the liquid level and automatically flow outto realize automatic collection. In the process, the thermoelectric conversion system timely absorbs the hydrates to produce released heat, so that on one hand, heat accumulation is avoided, the supercooling degree required for production of the hydrates is ensured, the hydrate production efficiency is further improved, the demand on cold energy input in the synthesis kettle is reduced at the same time, and the energy consumption is lowered; and on the other hand, according to the Seebeck effect, the thermoelectric conversion system converts the heat in the hydrate production process to the electric energy, and a refrigeration device can be driven, so that the refrigeration cost of the system is reduced, and the economy of the device is increased.

Owner:DALIAN UNIV OF TECH

A control method for reducing the noise of an air conditioner indoor unit and a multi-connected air conditioner

ActiveCN107062580BReduce cavitation noiseSolve the problem of liquid flow noiseMechanical apparatusNoise suppressionEngineeringMechanical engineering

The invention discloses a control method for reducing the noise of an indoor unit of an air conditioner, the air conditioner includes an outdoor unit and an indoor unit, the indoor unit includes an expansion valve of the indoor unit, the outdoor unit includes a compressor and an outdoor heat exchanger, and, A subcooler is also provided between the outdoor heat exchanger and the expansion valve of the indoor unit, and the subcooler includes a subcooler expansion valve; the control method includes the steps of: S10, controlling the air conditioner in cooling mode Start up; S20, control the opening degree EXV1 of the expansion valve of the subcooler and the opening degree EXV2 of the expansion valve of the internal unit, so as to establish the system subcooling degree and ensure the superheating degree of the internal unit. The control method of the present invention can reduce the cavitation noise of the indoor unit when the air conditioner is refrigerated and starts running, and can effectively solve the problem of the liquid flow noise of the indoor unit. The invention also discloses a multi-connected air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

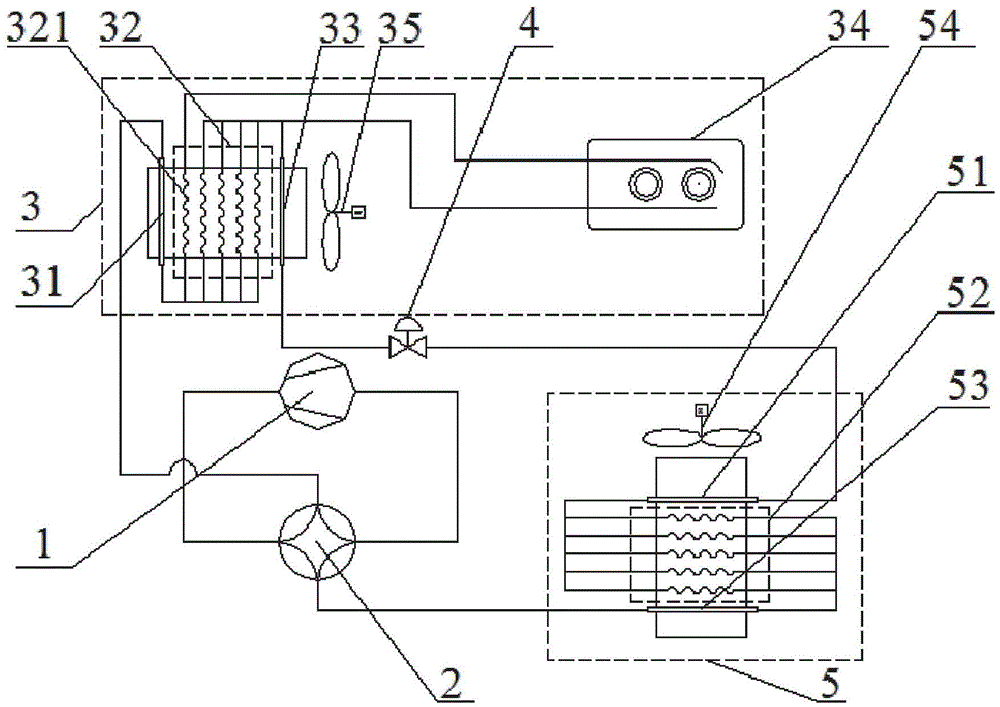

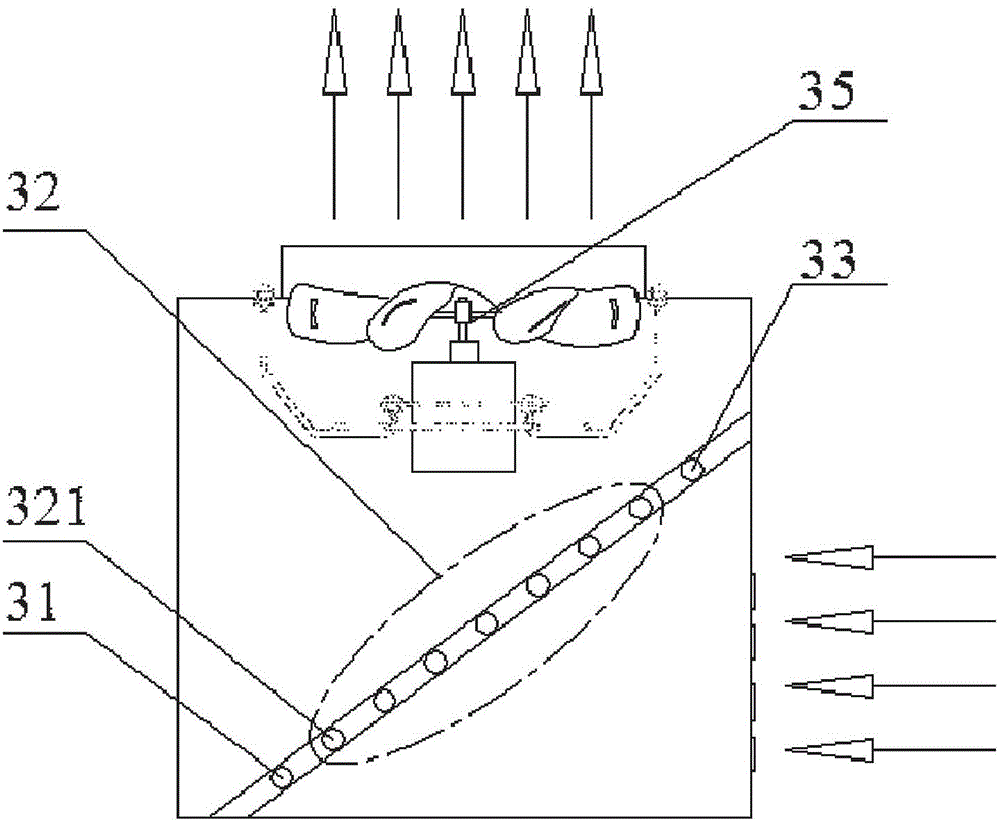

A heat pump unit using a secondary heat exchanger

ActiveCN105546819BImprove heat transfer efficiencyImprove heat transfer effectFluid heatersPlate heat exchangerThermal insulation

Owner:FOSHAN GUANGTENG NEW ENERGY CO LTD

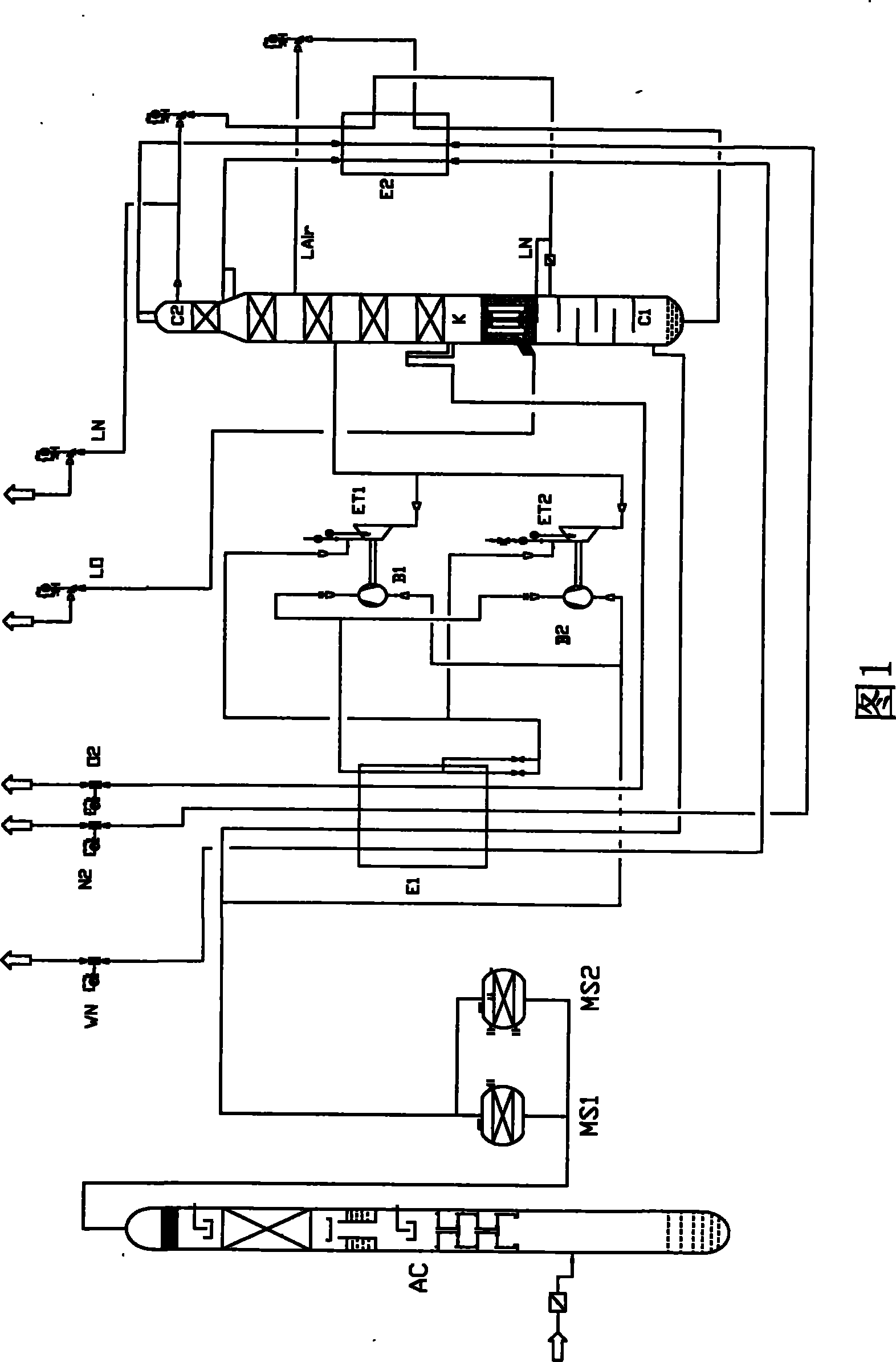

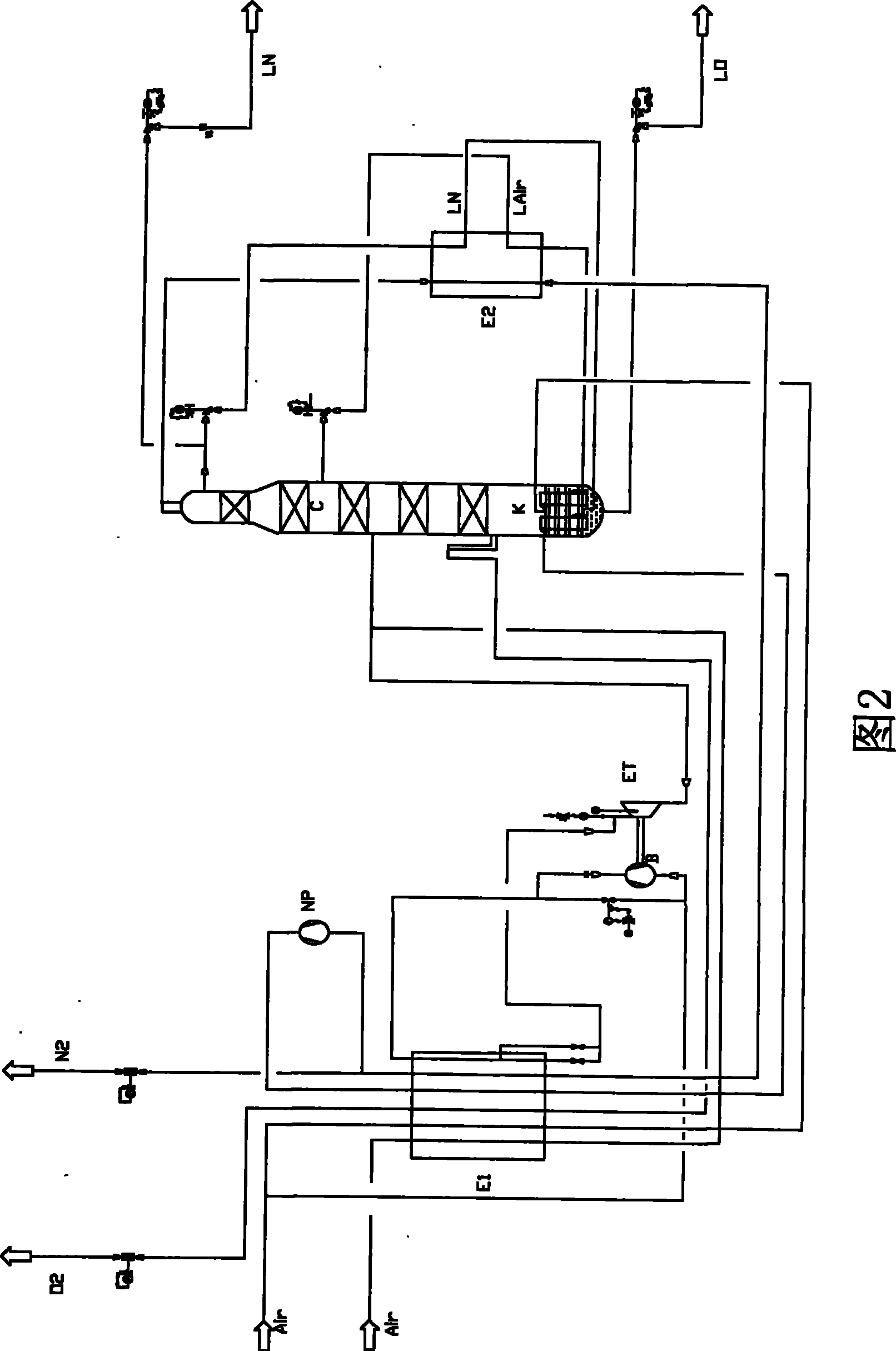

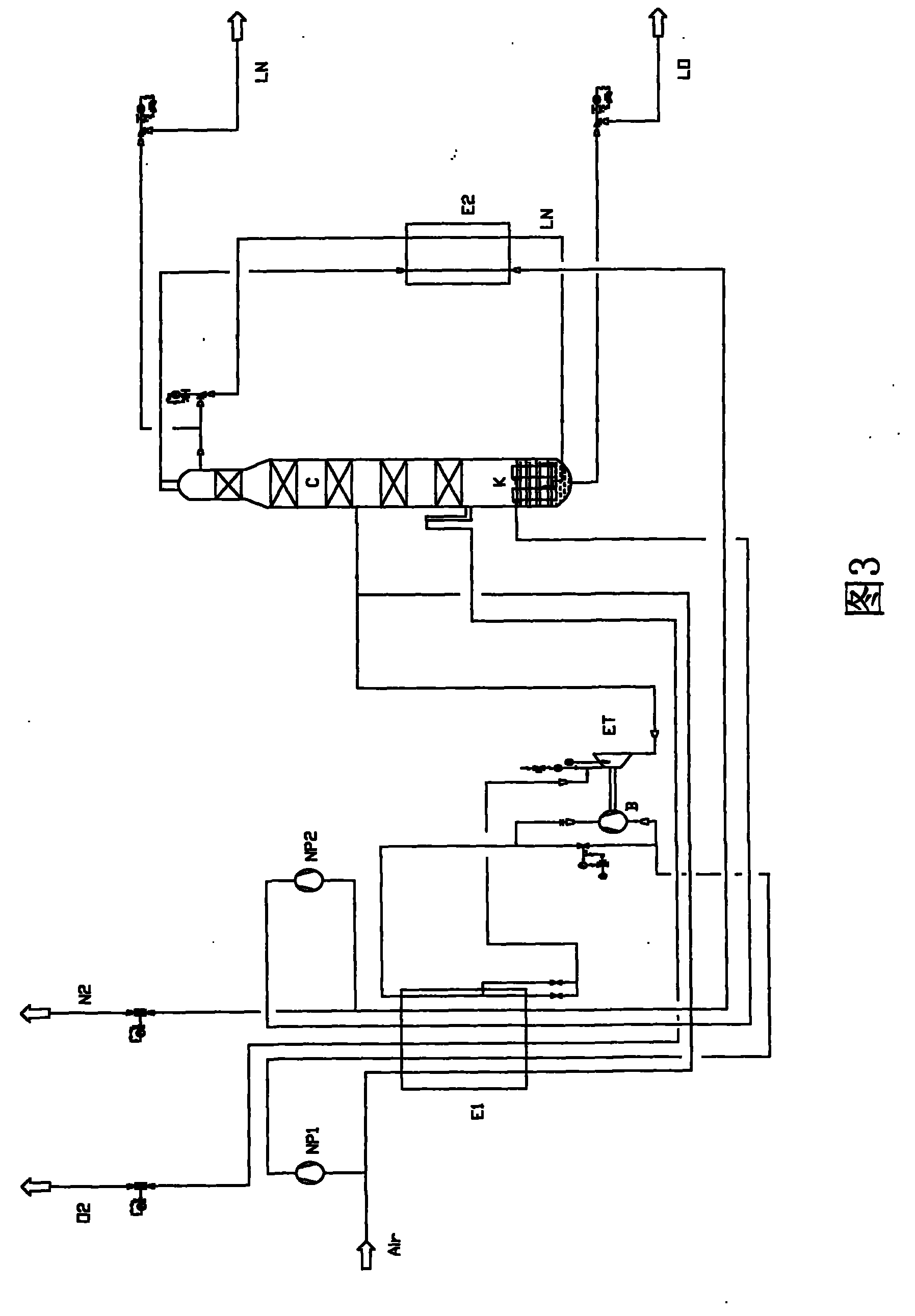

Ultra-low pressure single-column deep-cooling space division technique

InactiveCN101464085BGuaranteed purityHigh puritySolidificationLiquefactionDistillationAir separation

The invention discloses an ultra-low-pressure single-tower cryogenic air separation process. The process comprises the compression of air or oxygen-rich air, dewatering, purification and heat exchange of the air or the oxygen-rich air, compression and heat exchange of nitrogen, expansion refrigeration of nitrogen or air, preparation of liquid nitrogen or liquid air (or liquid oxygen-rich air), preparation of gas oxygen and gas nitrogen by ultra-low-pressure single-tower distillation and other steps. As the distillation is completely operated under the single-tower low pressure and a nitrogen compressor is provided, the purity of the liquid nitrogen is completely ensured, the distillation process is easy to operate, the resistance is small, the low liquid-gas ratio can be adopted, and the process can realize energy conservation, low project cost, convenient operation and regulation, flexible product proposal and easy formation of a large-scale combined oxygen-making unit with an oxygen-rich device, thereby reducing energy consumption, realizing large-scale devices and greatly improving nitrogen output under the same oxygen-making amount.

Owner:北京名都厚德科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com