Degradable gas hydrate accelerant and preparation method thereof

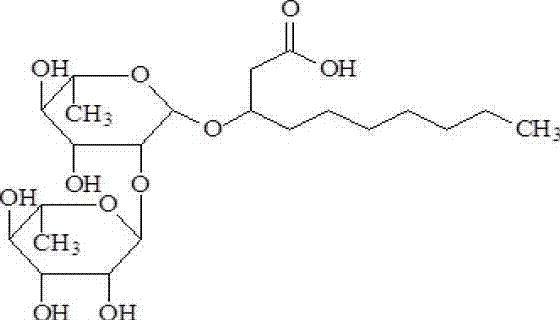

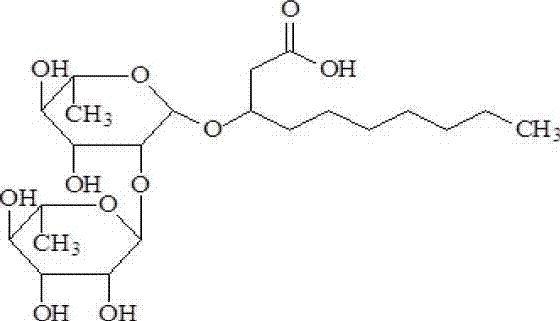

A gas hydrate and accelerator technology, which is applied in the field of preparation of degradable gas hydrate high-efficiency accelerators, can solve problems such as pollution and complex treatment of experimental waste liquid, achieve low dosage, wide application range, and promote efficient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

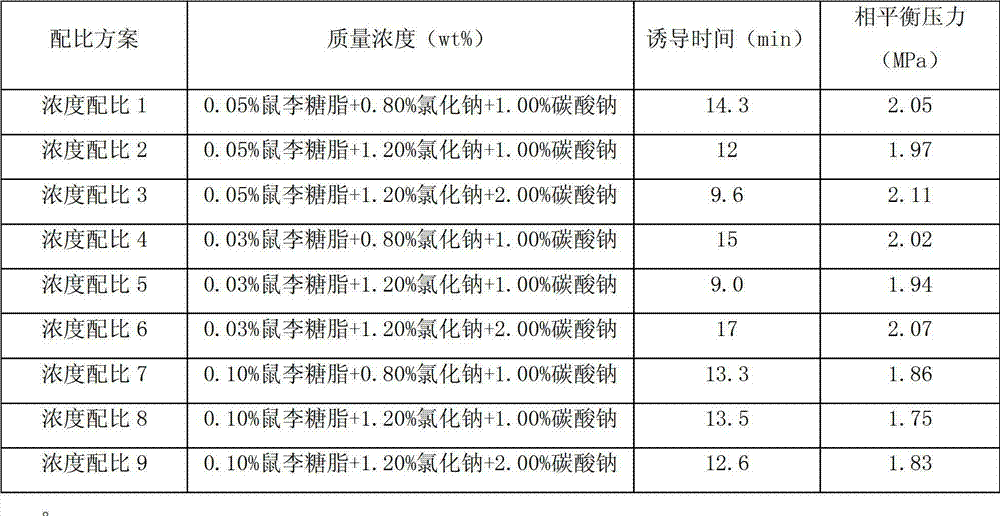

Embodiment 1

[0031] Prepare a compound accelerator solution with a mass concentration of 0.05% rhamnolipid + 0.80% sodium chloride + 1.00% sodium carbonate, take 200ml and inject it into the reactor (about 1 / 2 height of the window), set the temperature of the constant temperature water bath, and set the initial temperature 5°C, the experimental gas uses 99.9% CO 2 Gas, after the temperature stabilizes, start to inhale. After the inhalation is completed, start the tank and stir at 400-500rpm. After about 14.3min, the hydrate begins to form, and the phase equilibrium pressure is 2.05Mpa.

[0032] Specific steps are as follows:

[0033] (1) Prepare the solution: Use an electronic balance with an accuracy of 0.001g to accurately weigh the reagents and prepare a reaction solution with a corresponding concentration according to the experimental requirements, and store it for the experiment.

[0034] (2) Refrigeration: Turn on the low-temperature constant temperature circulation tank, preset the...

Embodiment 2

[0040]Prepare a composite accelerator solution with a mass concentration of 0.05% rhamnolipid + 1.20% sodium chloride + 2.00% sodium carbonate, take 200ml and inject it into the reactor (about 1 / 2 height of the viewing window), set the temperature of the constant temperature water bath, and set the initial temperature 5°C, the experimental gas uses 99.9% CO 2 Gas, after the temperature is stabilized, start to inhale, after the inhalation is completed, start stirring in the kettle at 400-500rpm, after about 9.6min, the hydrate begins to form, and the phase equilibrium pressure is 2.11Mpa.

Embodiment 3

[0042] Prepare a compound accelerator solution with a mass concentration of 0.03% rhamnolipid + 0.80% sodium chloride + 1.00% sodium carbonate, take 200ml and inject it into the reactor (about 1 / 2 height of the viewing window), set the temperature of the constant temperature water bath, and set the initial temperature 5°C, the experimental gas uses 99.9% CO 2 Gas, after the temperature stabilizes, start to inhale, after the inhalation is completed, start stirring in the kettle at 400-500rpm, after about 15min, the hydrate begins to form, and the phase equilibrium pressure is 2.02Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com