Turbo refrigeration machine

A turbo refrigerator and refrigerant technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as low density, and achieve the effect of ensuring flow, efficient operation, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

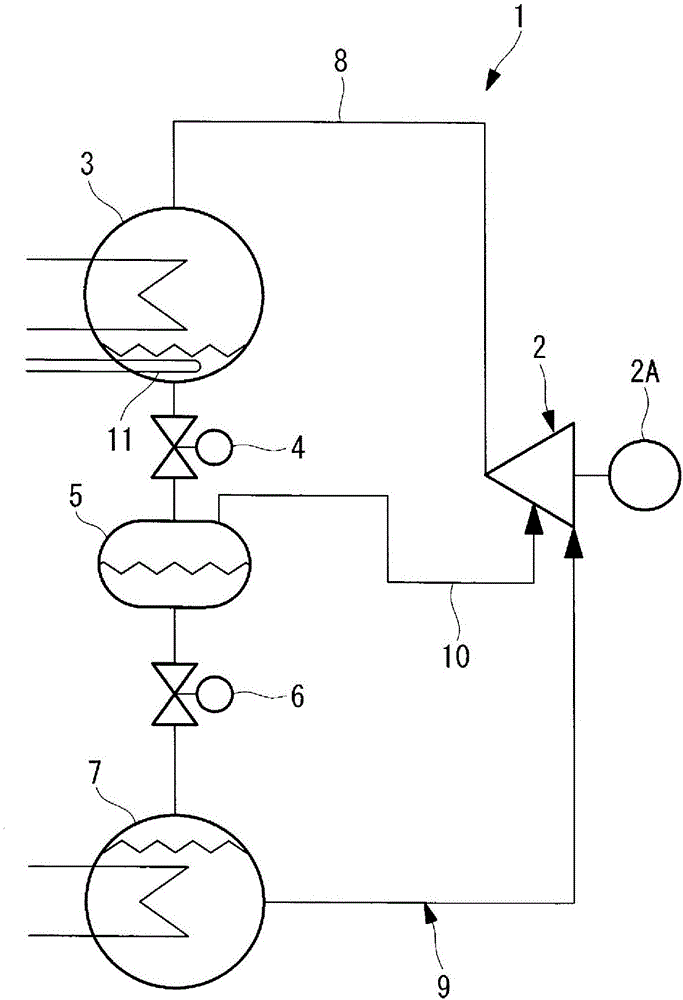

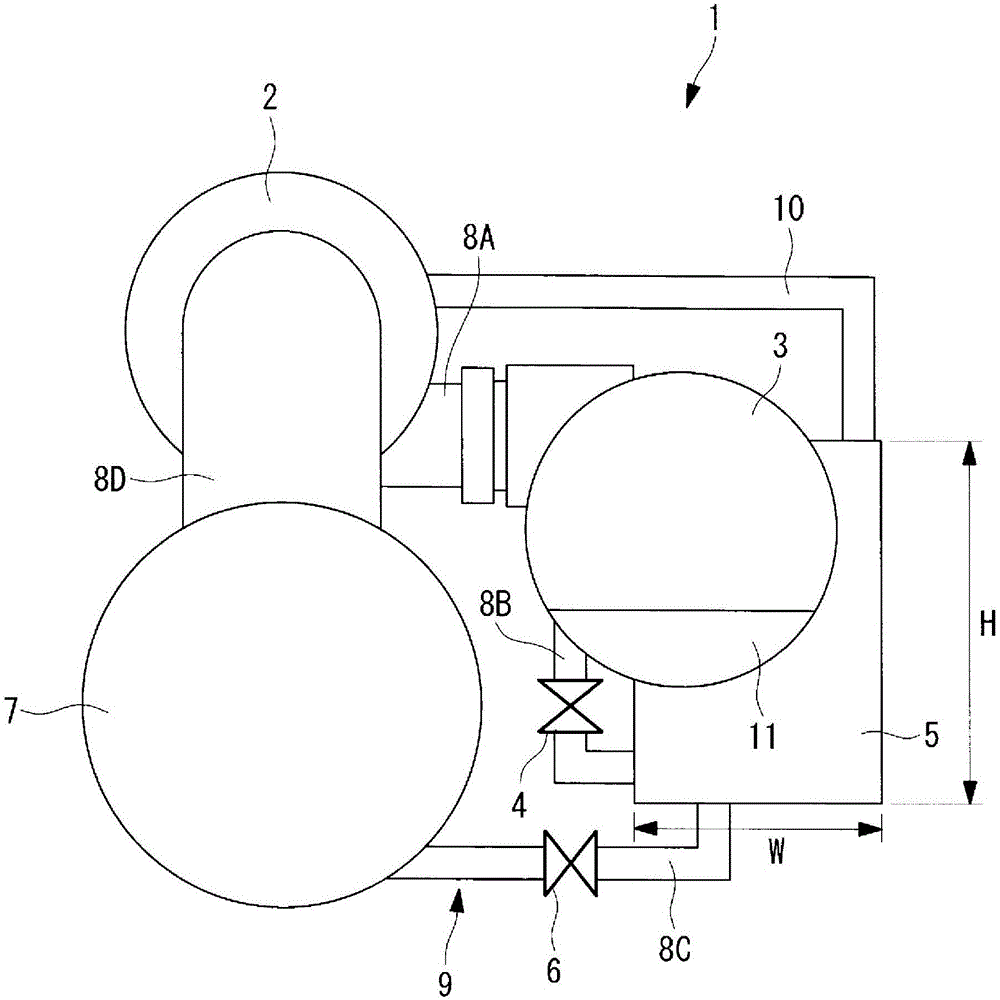

[0029] Below, use figure 1 and figure 2 A first embodiment of the present invention will be described.

[0030] figure 1 A refrigeration cycle diagram showing the turbo refrigerator according to the first embodiment of the present invention, figure 2 A configuration diagram showing the arrangement of each device constituting the turbo refrigerator.

[0031] The turbo refrigerator 1 is driven by a motor 2A, and has a closed-loop refrigeration cycle 9, which is formed by connecting the following equipment through the refrigerant piping 8 in the following order: a multi-stage turbo compressor (also referred to simply as a compressor) 2, It compresses the refrigerant; the shell-and-tube condenser 3 condenses and liquefies the high-temperature and high-pressure refrigerant gas compressed by the compressor 2; The pressure is reduced to an intermediate pressure; the intercooler (gas-liquid separator) 5 functions as an economizer; the second expansion valve 6 as a lower-stage pr...

no. 2 Embodiment approach

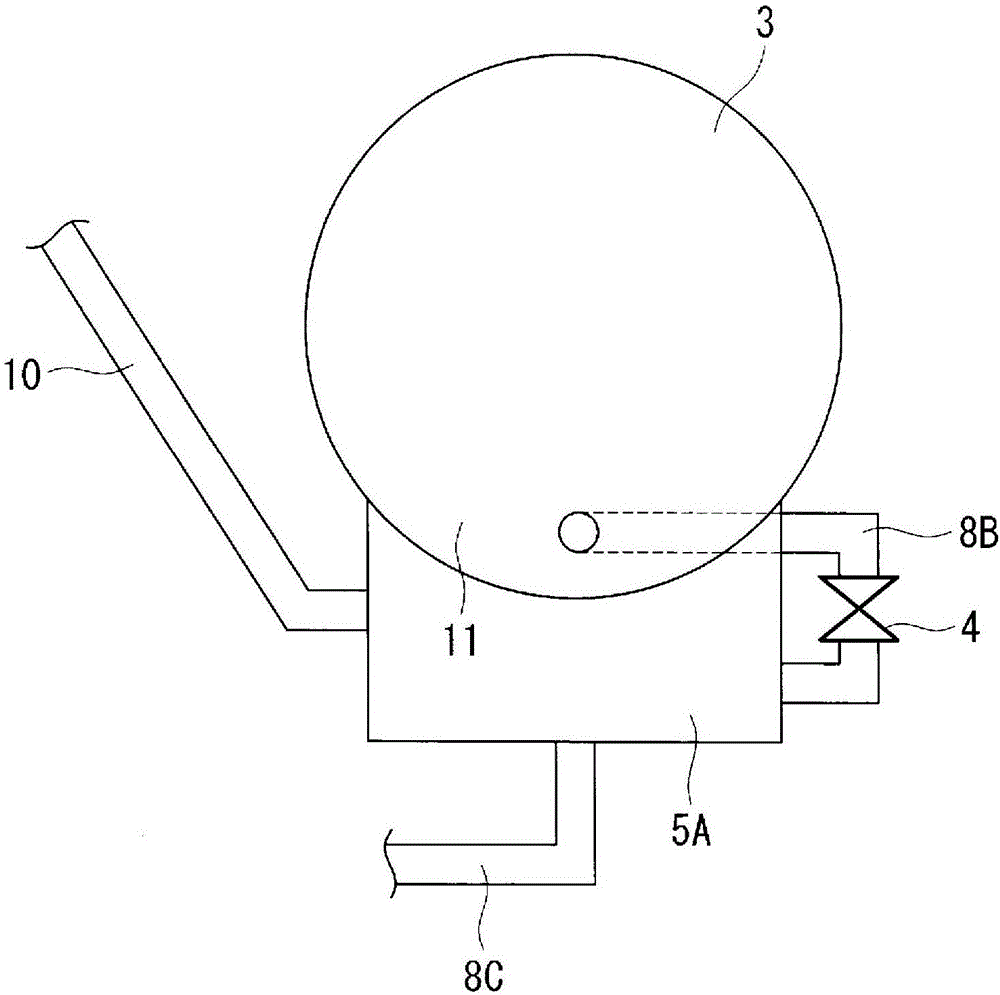

[0052] Next, use image 3 A second embodiment of the present invention will be described.

[0053] In this embodiment, the structure of the intercooler 5A integrated with the condenser 3 and the subcooler 11 is different from that of the above-mentioned first embodiment. Other points are the same as those of the first embodiment, and thus description thereof will be omitted.

[0054] In the present embodiment, the intercooler 5A is integrally formed with a part of the container wall as a common wall so as to cover substantially the entire bottom area of the circular cavity-shaped container constituting the condenser 3 and the subcooler 11 .

[0055] In this manner, the intercooler 5A has an integral structure with a part of the container wall as a common wall so as to cover substantially the entire area of the bottom of the condenser 3 and the subcooler 11 . Thus, the bottom of the condenser and the subcooler 11 where the condensed and liquefied refrigerant is deposited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com