Ultra-low pressure single-column deep-cooling space division technique

A cryogenic air separation and ultra-low pressure technology, applied in cold treatment separation, refrigeration and liquefaction, liquefaction, etc., can solve problems such as large resistance, complicated process, and difficulty in producing high-purity nitrogen, so as to realize large-scale equipment and increase nitrogen production. Yield, the effect of increasing the number of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

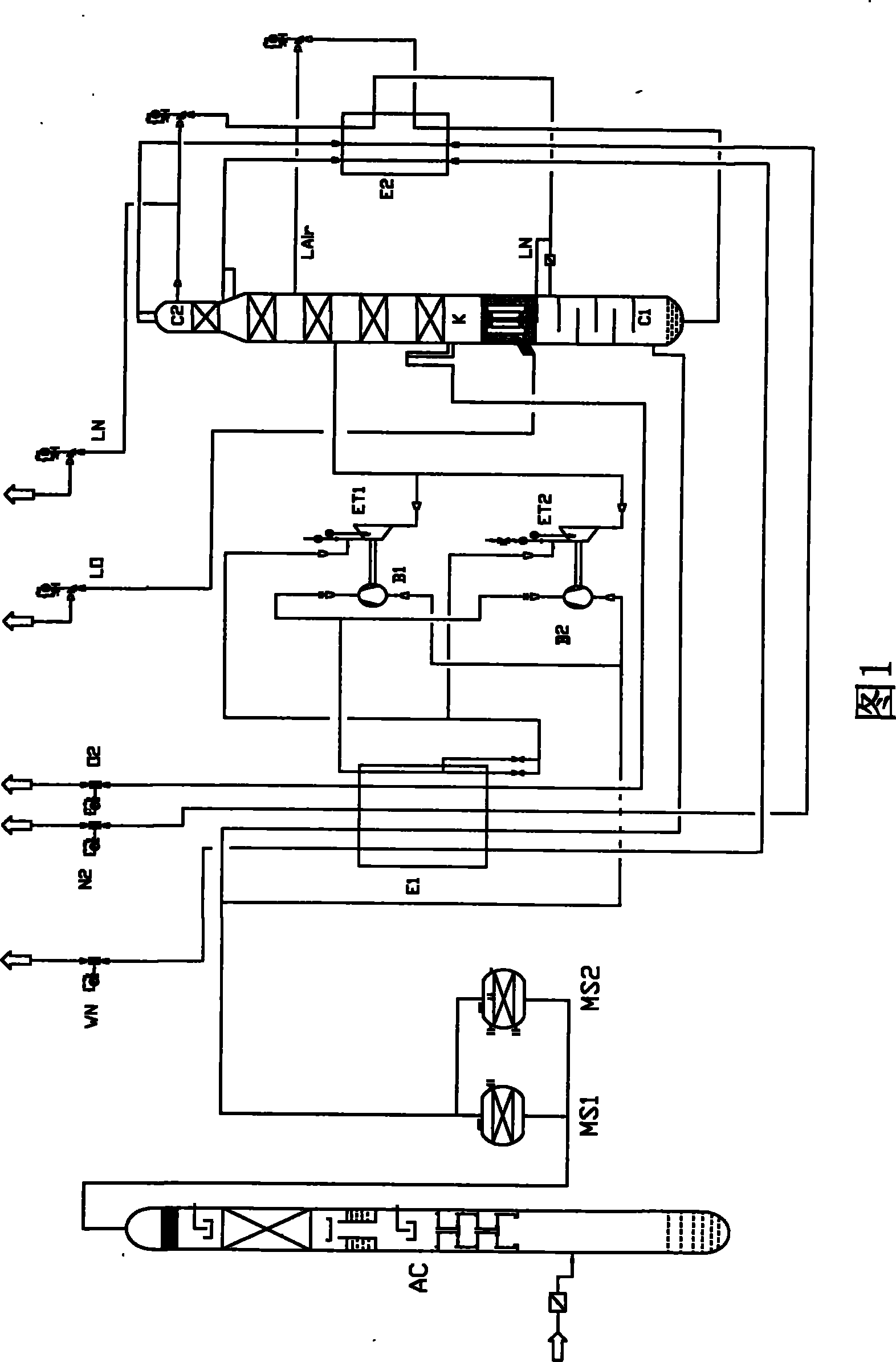

[0042] The production process of the existing typical cryogenic air separation process is a full-low pressure double-column rectification separation process. As shown in Figure 1, the air is compressed to 0.58 ~ 0.6MPa (the pressure refers to absolute pressure, the same below), and the water is washed in the tower. AC cooling, freezing and water removal, purified by parallel purifier A MS1, purifier B MS2, a small part of turbocharger A B1, turbocharger B B2 in parallel to pressurize; expander A ET1, expander B After the expansion of ET2, the pressure drops to 0.13-0.15MPa, and after the heat exchange between the main heat exchanger E1 and the reflux gas, it enters the upper rectification tower C2 for rectification, and most of it passes through the main heat exchanger E1 and the reflux gas. , enter the lower rectification tower C1 to produce liquid nitrogen and liquid air, the liquid nitrogen and liquid air pass through the cooler E2 and the reflux gas nitrogen is subcooled an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com