Novel plate type heat exchanger liquid divider

A technology of plate heat exchanger and liquid separator, which is applied in the direction of evaporator/condenser, heat pump, refrigeration and liquefaction, and can solve the problem of uneven distribution of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

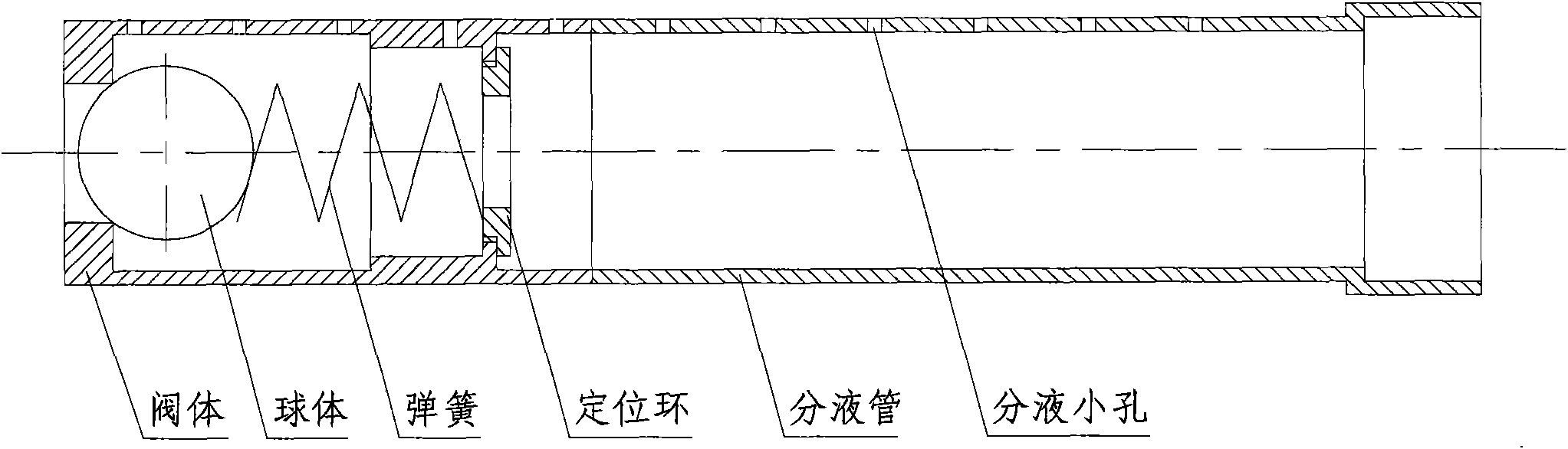

[0006] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a structural diagram of a new type of plate heat exchanger liquid distributor. The left part of the liquid distributor is a one-way valve, and the right part is a liquid distribution pipe. The valve body of the one-way valve and the liquid distribution pipe are polished smooth after welding The valve body of the check valve and the pipe wall of the liquid pipe are drilled with small liquid separation holes, and the aperture and quantity of the small liquid separation holes are determined by the specific model.

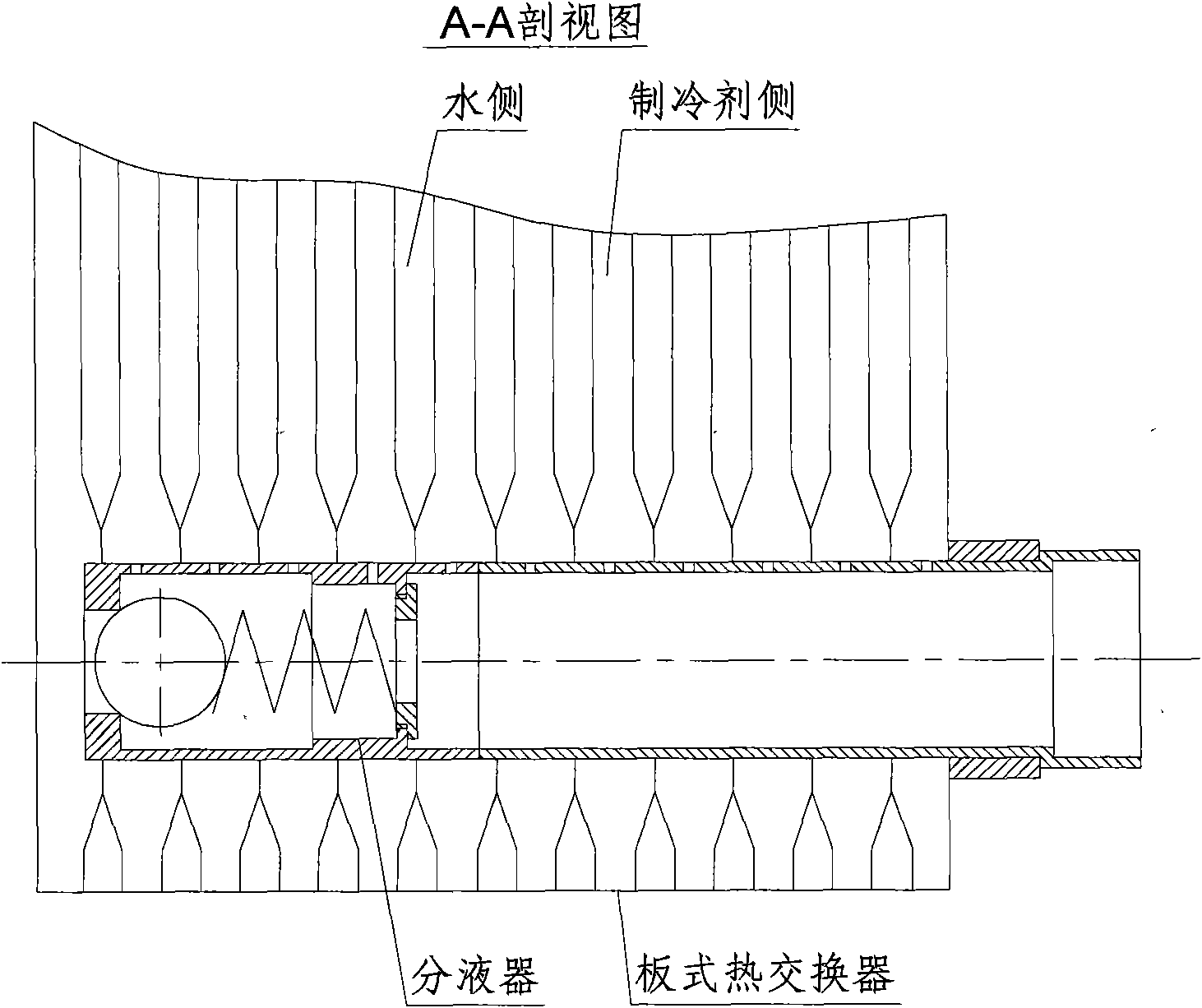

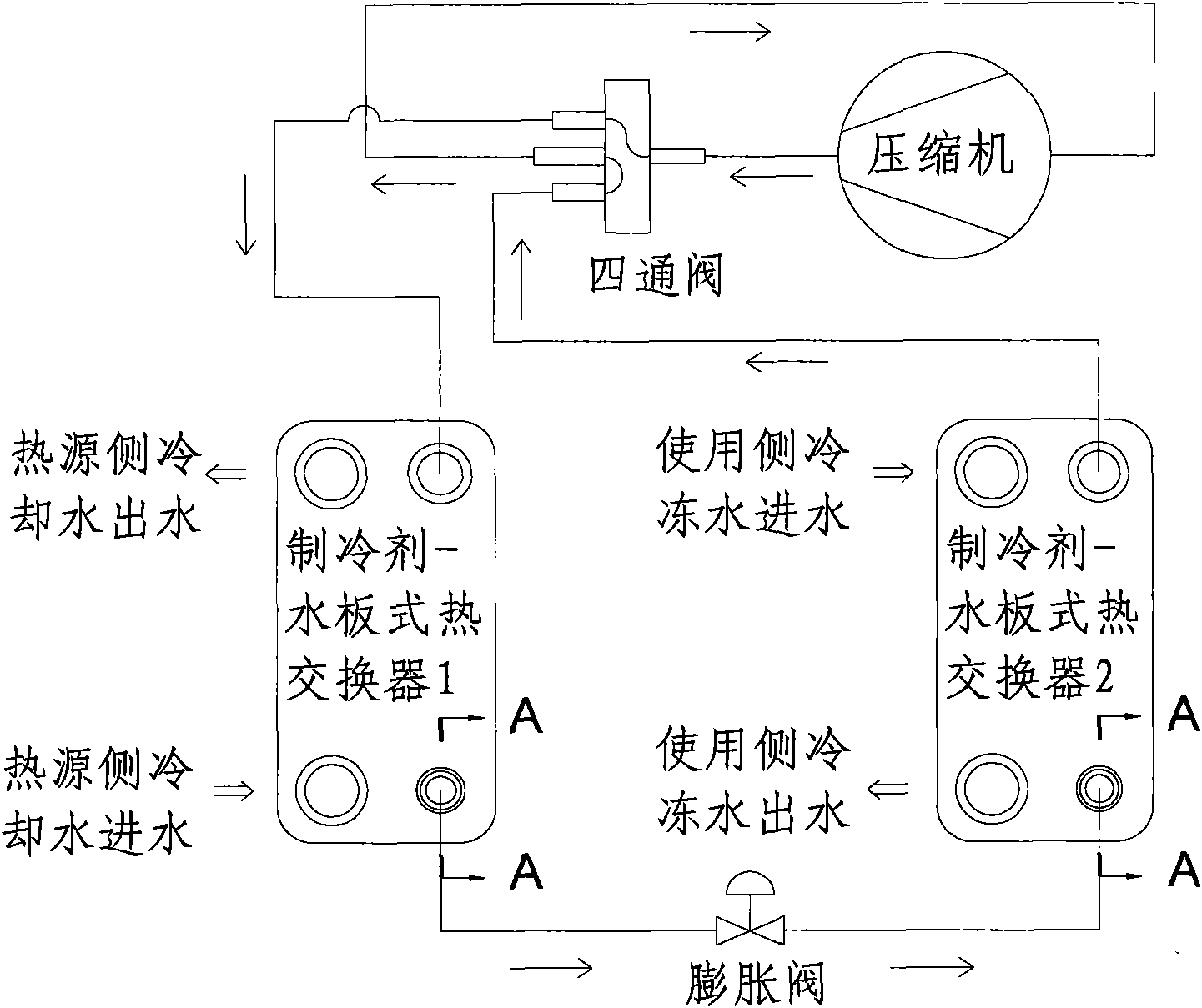

[0007] figure 2 It is an assembly drawing of a new type of plate heat exchanger liquid separator and plate heat exchanger, that is, the A-A sectional view in the system flow chart. When the plate heat exchanger is used as an evaporator, the refrigeration after throttling by the expansion valve When the refrigerant enters the liquid separator, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com