Four-stage cascade refrigerating device with multi-stage water cooler

A water cooler and cascade refrigeration technology, which is applied in the direction of compressors, subcoolers, and refrigerators with cascade operation, which can solve the problems of low refrigeration efficiency, fluctuation and deviation of working conditions, and overheating of compressor suction. and other problems, to achieve the effect of improving cooling capacity and cooling efficiency, ensuring safe operation and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

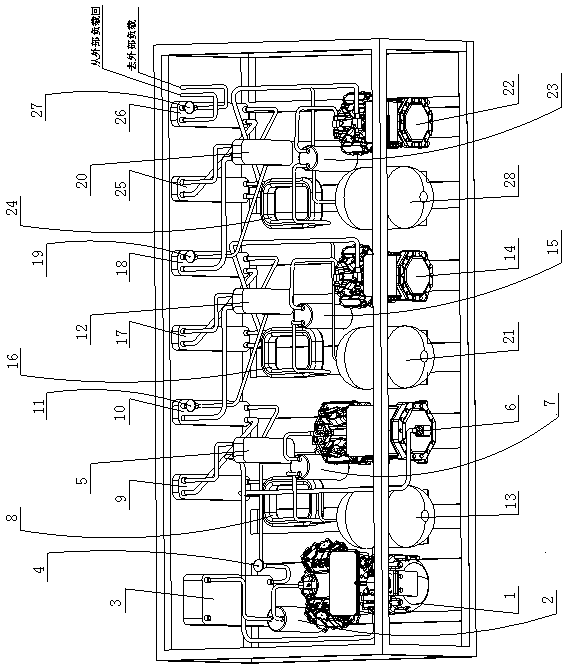

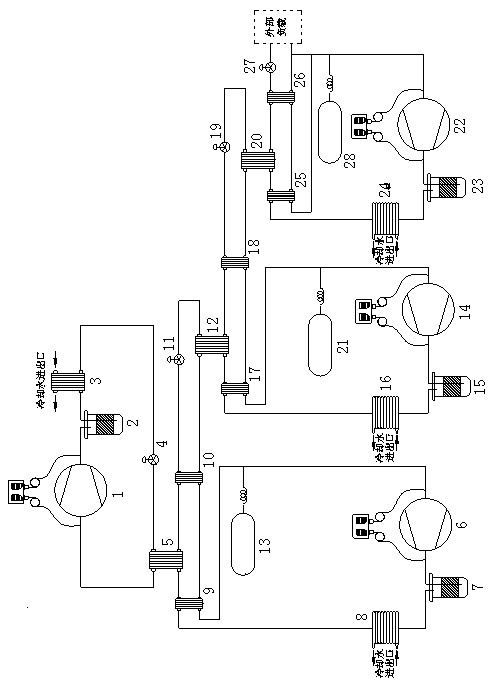

[0025] Such as figure 1 As shown, this embodiment provides a four-stage cascade refrigeration device with a multi-stage water cooler, which is formed by cascading four relatively independent refrigeration cycles. The first-stage refrigeration cycle includes a first-stage compressor 1, a first-stage Oil separator 2, primary condenser 3, primary expansion valve 4, secondary condensing evaporator 5; the secondary refrigeration cycle includes secondary compressor 6, secondary oil separator 7, secondary water cooler 8, The secondary precooling regenerator 9, the secondary condensing evaporator 5, the secondary subcooling regenerator 10, the secondary expansion valve 11, the tertiary condensing evaporator 12, and the secondary expansion vessel 13; the tertiary refrigeration cycle includes Three-stage compressor 14, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com