Two-stage heat exchanger

A secondary heat exchanger and secondary heat exchange technology, which is applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problems of heat conduction and heat conduction, which can easily affect each other and reduce the heat exchange efficiency of heat exchangers. , to achieve the effect of maintaining supercooling, improving energy efficiency, and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

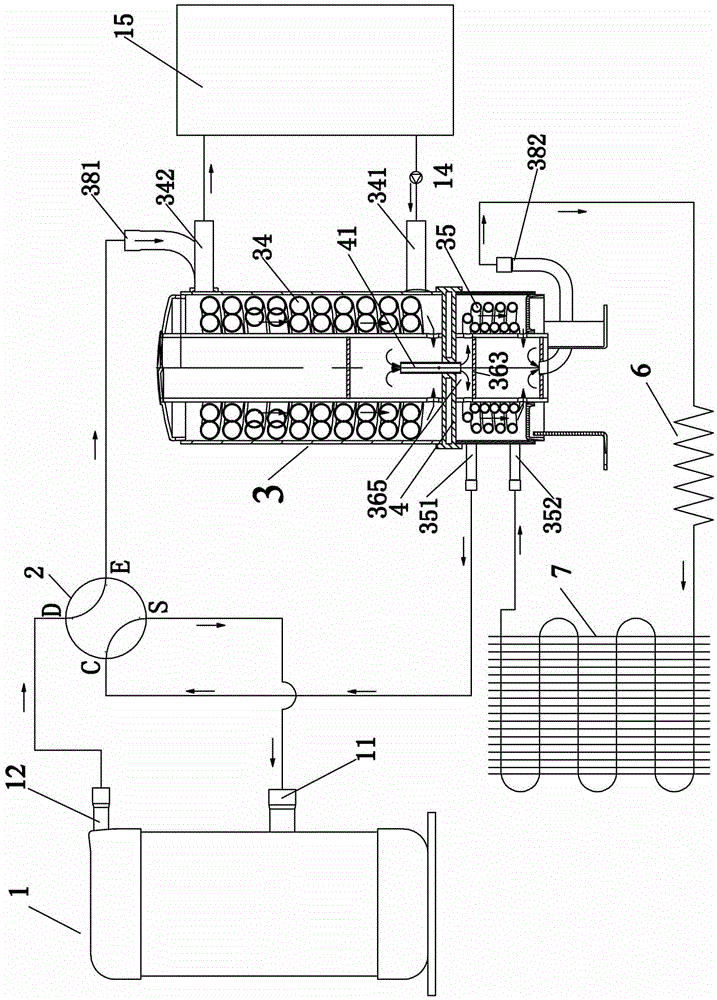

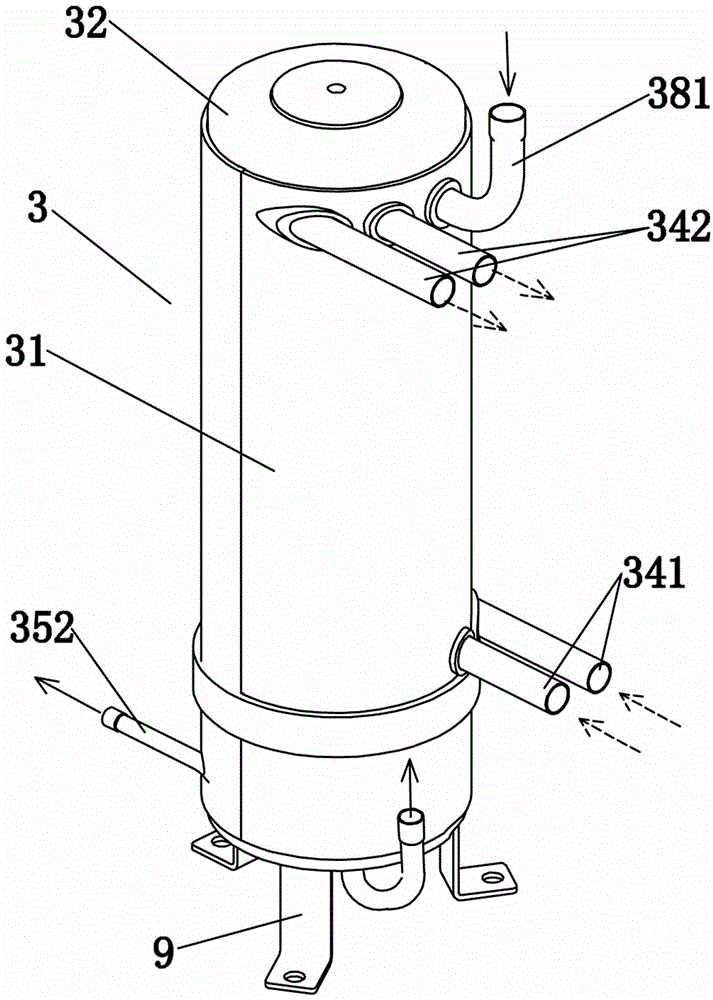

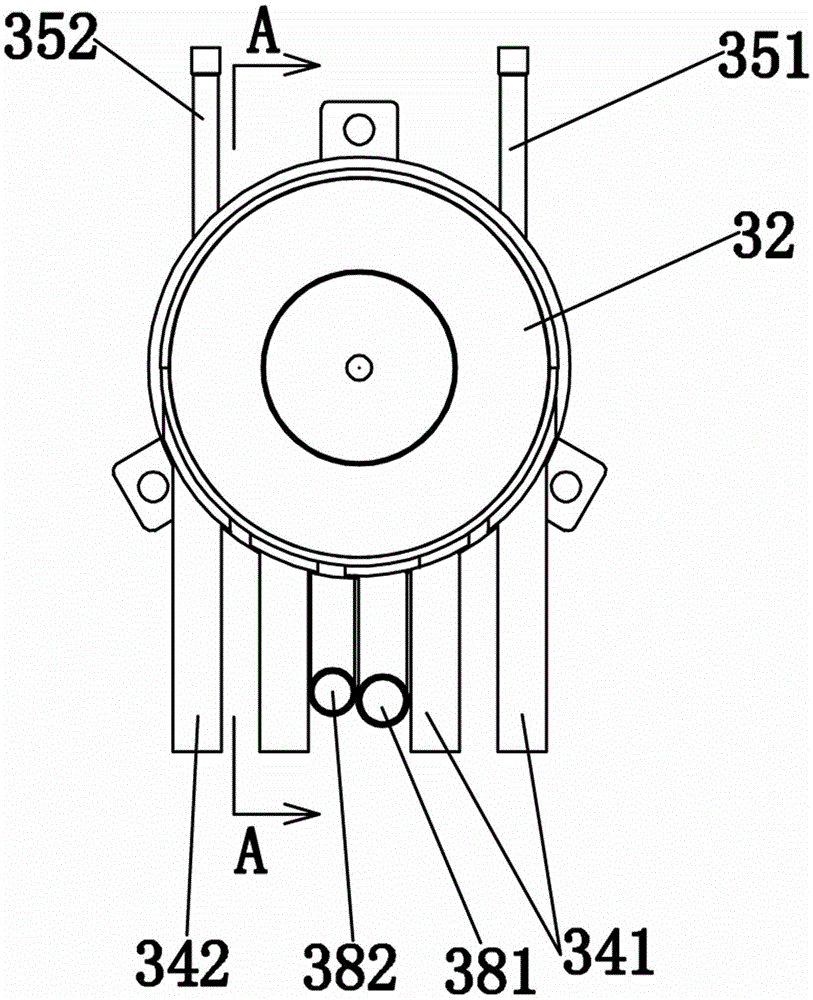

[0032] Embodiment one, such as Figure 1 to Figure 5 As shown, a heat pump water heater includes a compressor 1, a four-way valve 2, a secondary heat exchanger 3, a first throttling device 6, a second heat exchanger 7, and a water storage tank 15. The secondary heat exchanger 3 includes a housing 31, the housing 31 is divided into a primary heat exchange cavity 38 and a secondary heat exchange cavity 39 by a partition 4, and a primary heat exchange cavity 38 and a secondary heat exchange cavity 39 are respectively provided with a The first-stage heat exchange tube 34 and the second-stage heat exchange tube 35 , the partition plate 4 is provided with a communication channel 41 , and the communication channel 41 communicates with the first-stage heat exchange chamber 38 and the second-stage heat exchange chamber 39 .

[0033] The housing 31 is respectively provided with a first refrigerant inlet 381 and a first refrigerant outlet 382 corresponding to the primary heat exchange ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com