Heat utilization balance processor

A technology of balancing processors and heat exchange tubes, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc. Influence of safety, strong self-cleaning effect, effect of improving energy efficiency coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

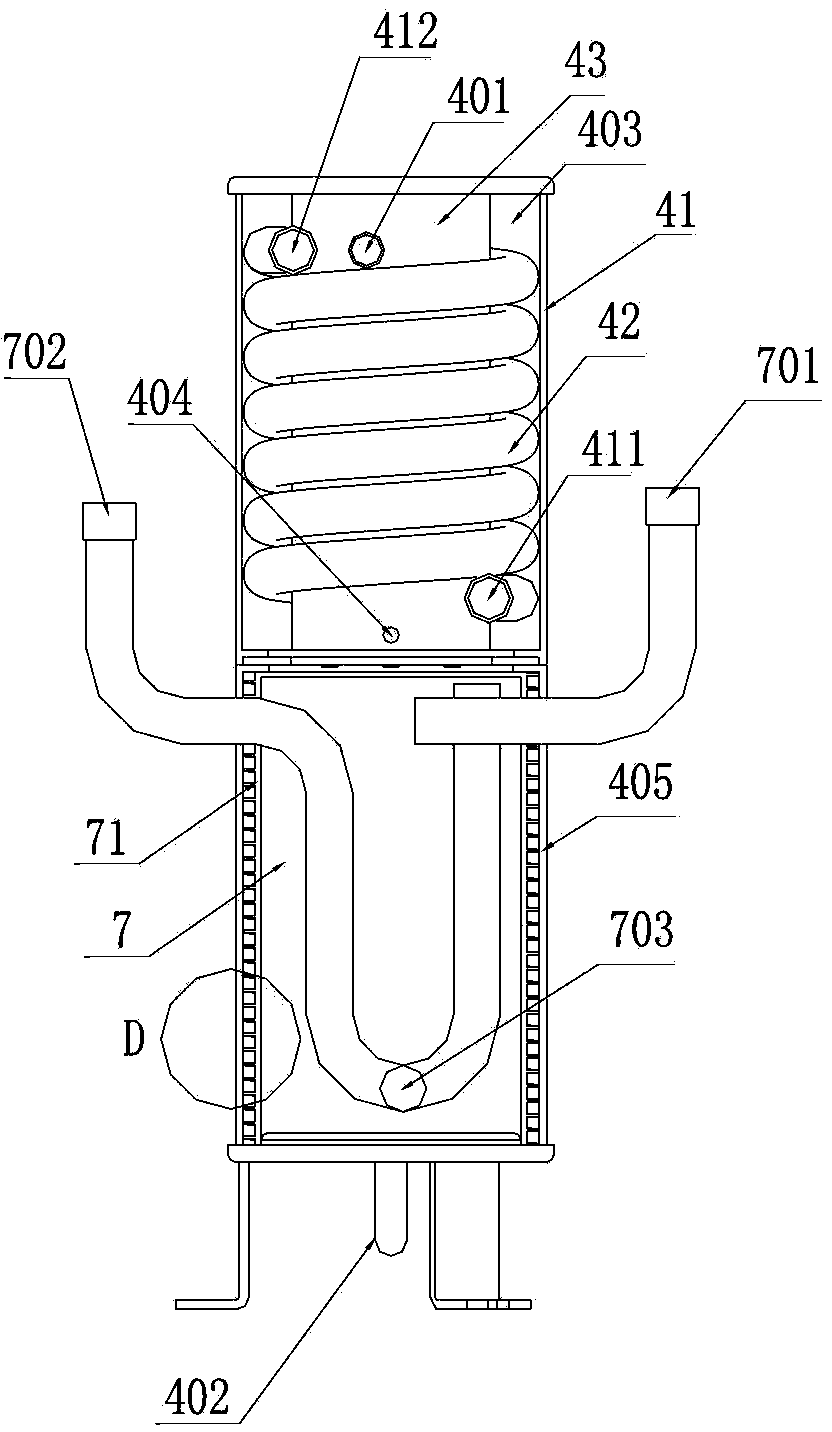

[0027] The heat utilization balance processor 4 of the present invention is used in a heat pump water heater or a refrigeration cycle system with a non-azeotropic mixed refrigerant, and includes a housing 41, a heat exchange tube 42, a working medium inlet 401, a working medium outlet 402, and a water inlet 411 , water outlet 412 and vapor-liquid separator 7, such as figure 1 , Figure 5 to Figure 7 shown.

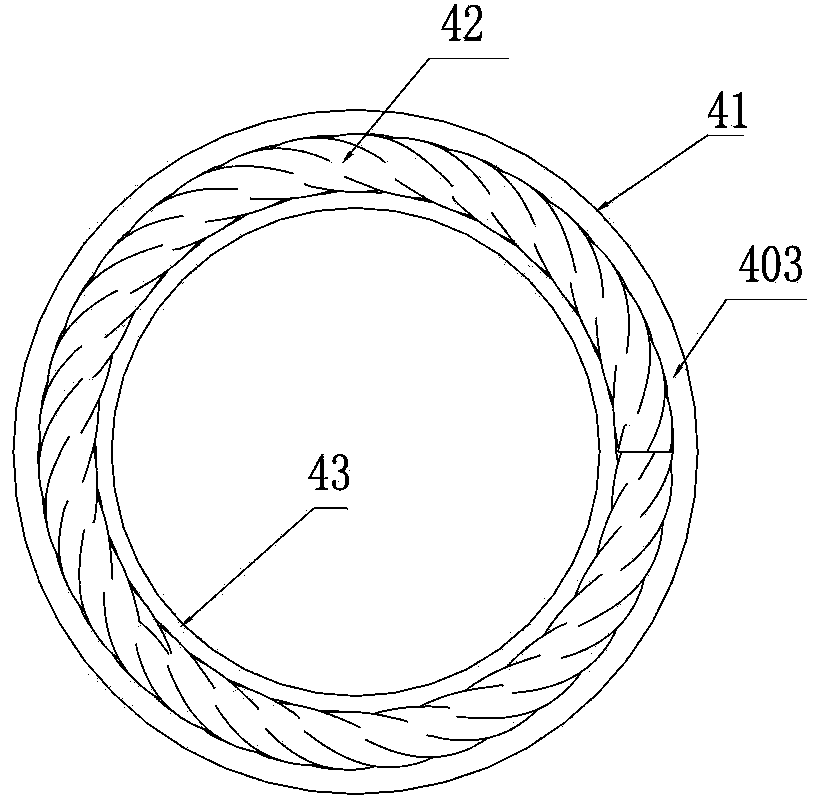

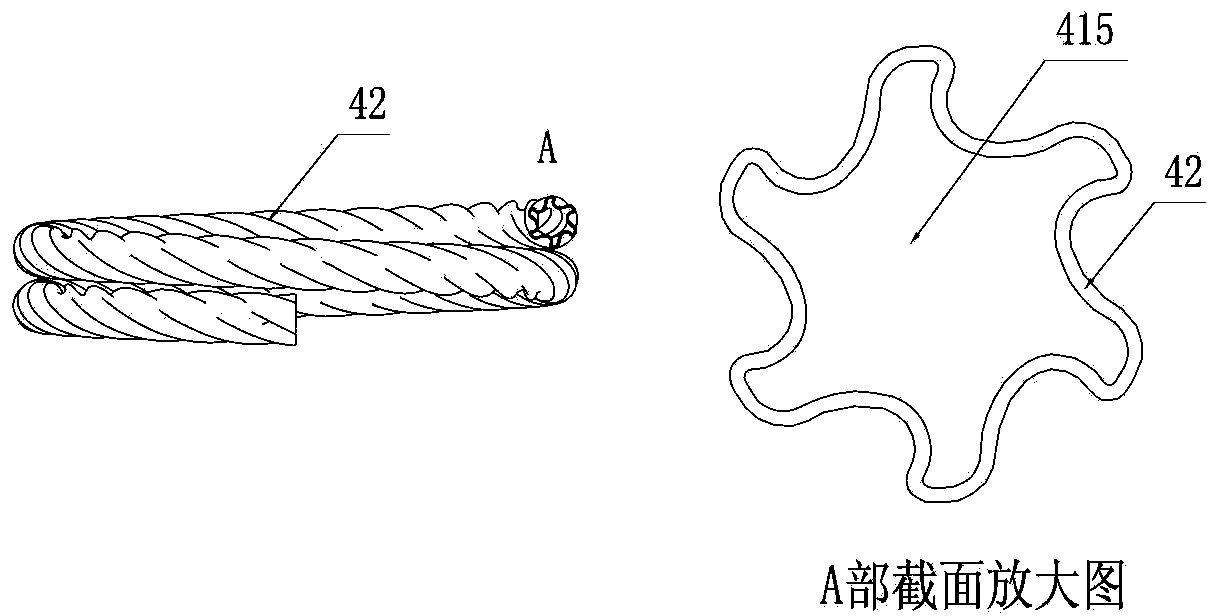

[0028] The upper half of the housing 41 is provided with an inner cylinder 43, and the space formed between the upper half of the housing 41 and the inner cylinder 43 constitutes a main heat exchange chamber 403; the heat exchange tube 42 is coiled in a spiral shape, and In the main heat exchange chamber 403, see figure 1 and figure 2 .

[0029] The vapor-liquid separator 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com