Test bed for valve electric device motor

A technology for motor testing and valve electric driving, which is applied in the direction of motor generator testing, measuring devices, testing of mechanical components, etc. It can solve the unfavorable design and production of valve electric device, the accuracy of data parameters is not high, and the actual performance of the motor cannot be accurately grasped. Parameters and other issues to achieve the effect of improving the design and production process and optimizing the design and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

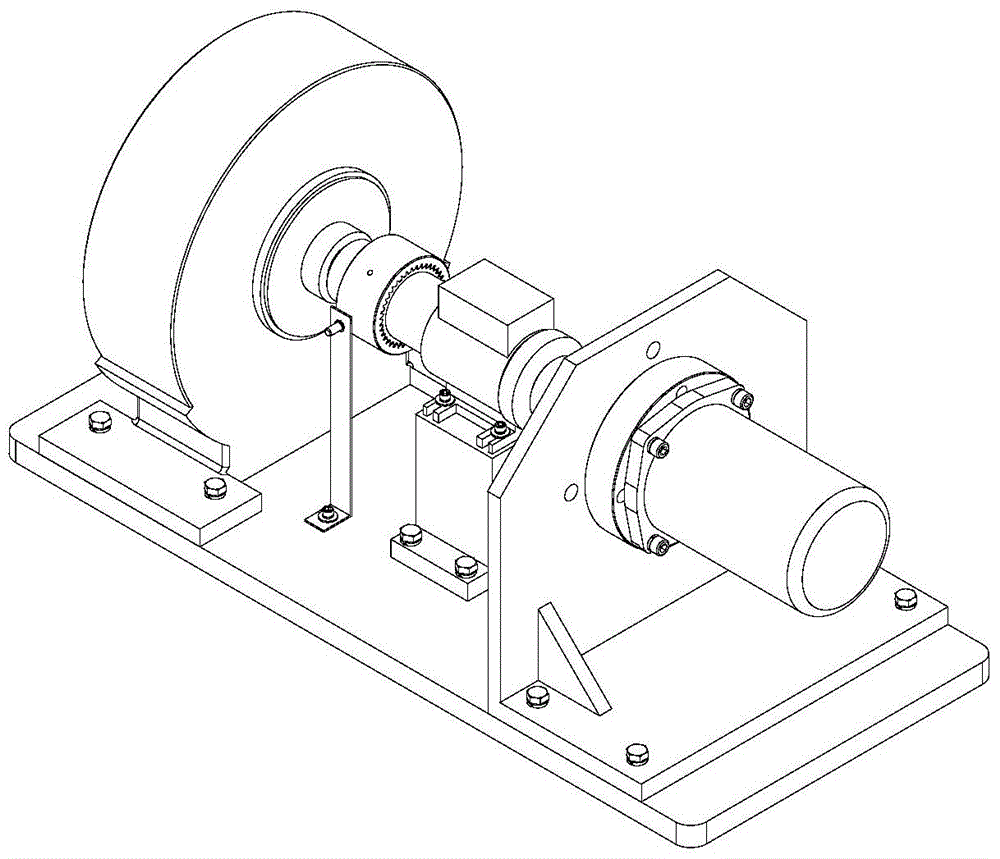

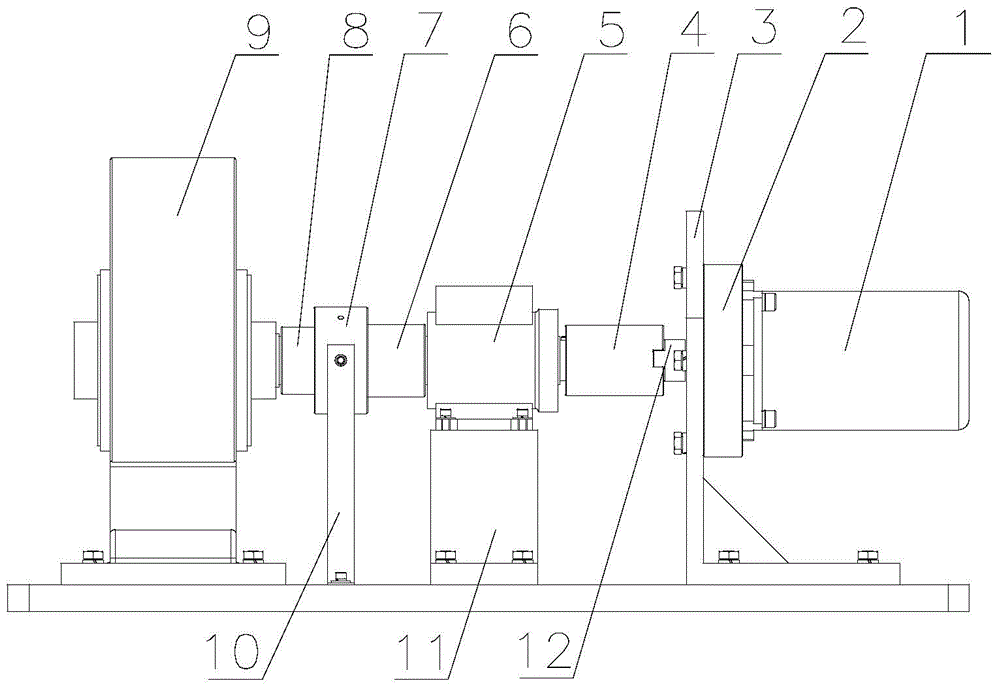

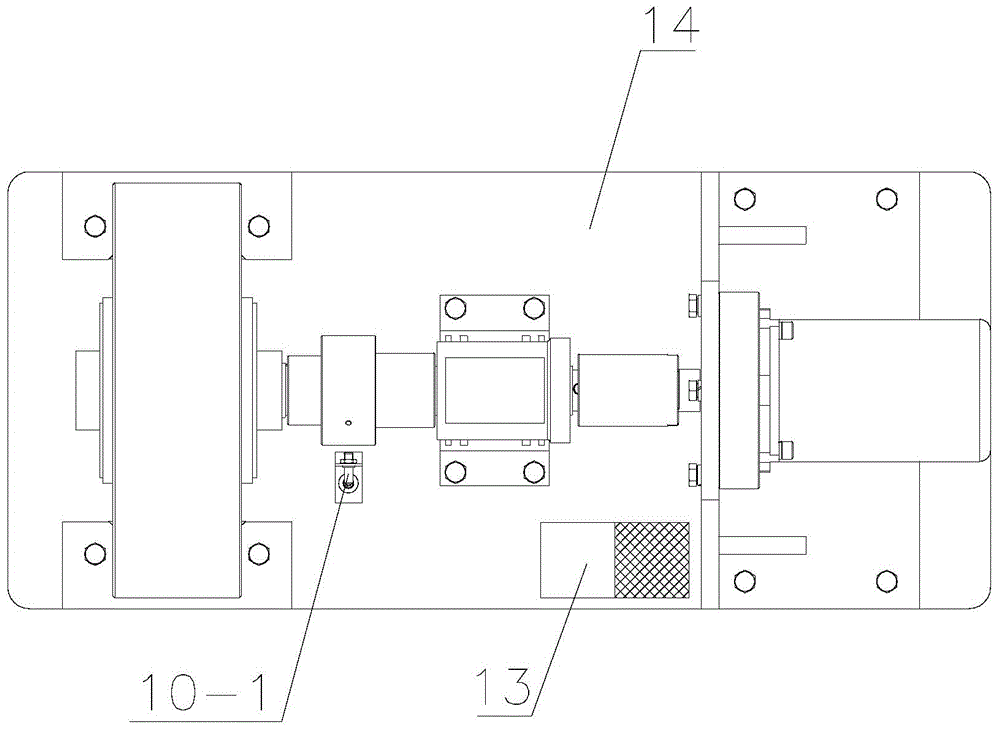

[0017] Such as figure 1 with 2 As shown, the valve electric device motor test bench includes a motor connector 12, a connecting flange 2, a torque sensor 5 and a base 14, on which the first bracket 11 and the second bracket 3 are installed, and the motor connector 12 and one end of the transmission shaft 4 Transmission connection, the other end of the transmission shaft 4 is in transmission connection with one end of the torque sensor 5, the other end of the torque sensor 5 is connected with a magnetic powder brake 9, the torque sensor 5 is installed on the first bracket 11, and the connecting flange 2 is fixedly installed on the second On the second support 3 , the axis of the connecting flange 2 coincides with the axis of the transmission shaft 4 , the motor 1 to be tested is installed on the connecting flange 2 , and the output end of the motor 1 is connected to the motor joint 12 in transmission.

[0018] Such as figure 1 with 2 As shown, a connecting shaft 6, a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com