System and method for creating and carrying out an installation cleaning process for process installations

A process technology and cleaning technology, applied in the direction of cleaning methods and appliances, general control systems, chemical instruments and methods, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

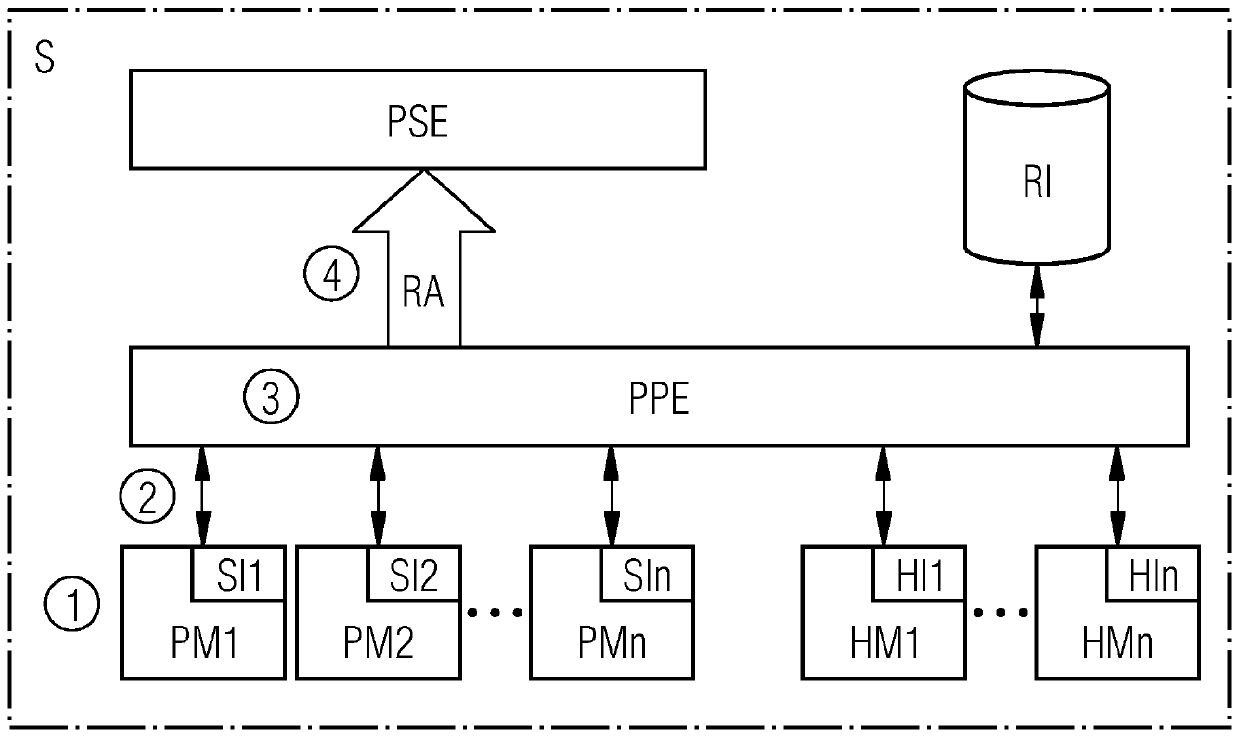

[0045] figure 1 An exemplary structure of a system S for creating and executing a facility cleaning process for a process technology facility is schematically shown. Here, the facility cleaning process is designed as a so-called clean-in-place or CIP process, and the process technology facility is set up or configured for cleaning in accordance with the CIP process, that is, the facility has CIP capability. The system S, which is the digital mapping of the process technology facility with respect to the cleaning process of the facility, is designed, for example, as a so-called cyber-physical production system (CPPS).

[0046] Here, the system S according to the invention has a plurality of process modules PM1, PM2, ..., PMn. The process technology facilities are mapped to these process modules PM1, PM2, ..., PMn, where these process modules represent the parts or components of the facility to be cleaned, such as boilers, tanks, containers, filters, heat exchangers, etc. , Inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com