Safety error prevention device for full-electronic fuse testing and use method of safety error prevention device

An error-proof and fuze technology, applied in the direction of measuring device, improvement of basic electrical components, measuring electricity, etc., can solve the problems of scrapping of all-electronic fuze products, damage of test equipment, explosion of detonator components, etc., to ensure the effect of safety test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

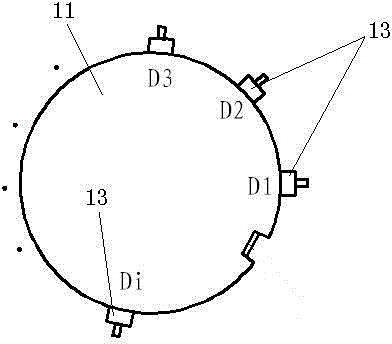

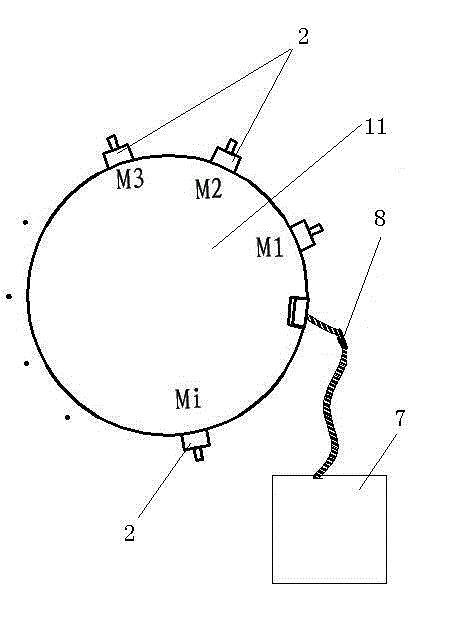

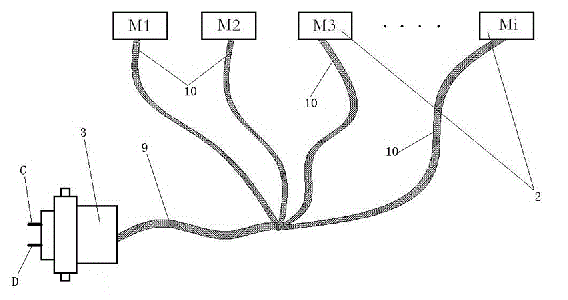

[0021] Example: see Figure 1 to Figure 7 .

[0022] A safety and anti-error device for full electronic fuze testing, the device includes a simulated load cable 1, a number of simulated loads 2, and a potential detection alarm device, and the simulated load cable 1 includes two main core wires 9, several connecting cables 10 and a plug 3, One end of the two main core wires 9 in the simulated load cable 1 is connected in series with several connecting cables 10, the other end of the main core wires 9 is connected to the plug 3, and the connecting cables 10 are connected to the two connection terminals A and B on the simulated load 2 , the potential detection alarm device is placed in the full electronic fuze test equipment 7, the potential detection alarm device includes a potential detection module 5 and an alarm module 6, the potential detection module 5 is connected to the socket 4 and matches the plug 3, the potential detection module 5 and the alarm module 6 connections. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com