Signal analysis device and automatic parameter entering and comparing system and method

A signal analysis and automatic input technology, applied in data acquisition and recording, electrical digital data processing, character and pattern recognition, etc., can solve the problems of data accuracy, there is no way to guarantee, parameter setting errors, product scrapping, etc., to eliminate records The problem of wrong production parameters, the effect of reducing mistakes and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

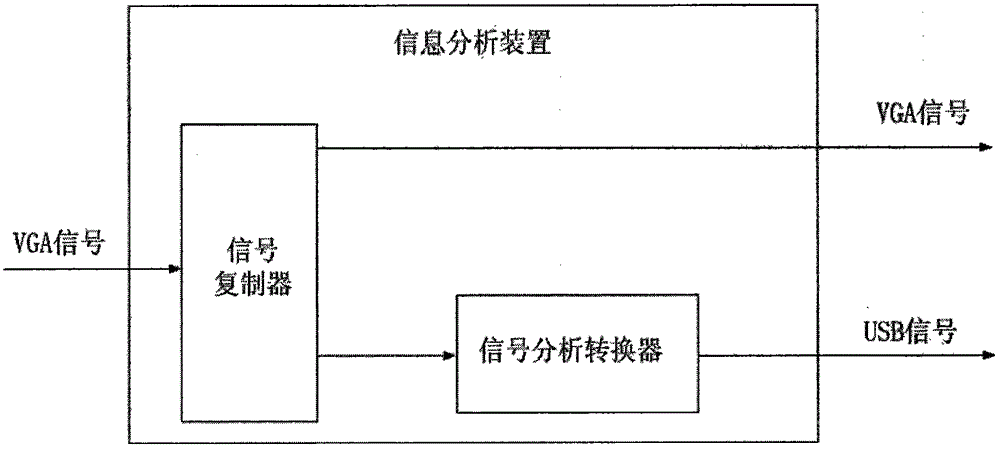

[0030] refer to figure 1 , which shows a functional block diagram of the signal analysis device proposed in this embodiment. In this embodiment, the signal analysis device includes: a signal replication module and a signal analysis conversion module. Wherein, the signal duplication module is used for receiving and duplicating a VGA (Video Graphic Array, display graphics array) signal. The signal analysis conversion module is used to convert the VGA signal into a USB (universal serial bus) signal.

[0031] Among them, the VGA signal is a common signal used when the host computer outputs to the display. However, each computer in the production equipment has only one VGA signal line. If it is used for external analysis, the display of the production equipment will not be displayed. In order not to affect The VGA data line is transmitted to the display of the production equipment, and the analysis signal can be obtained again. In this embodiment, the VGA signal is copied into tw...

Embodiment 2

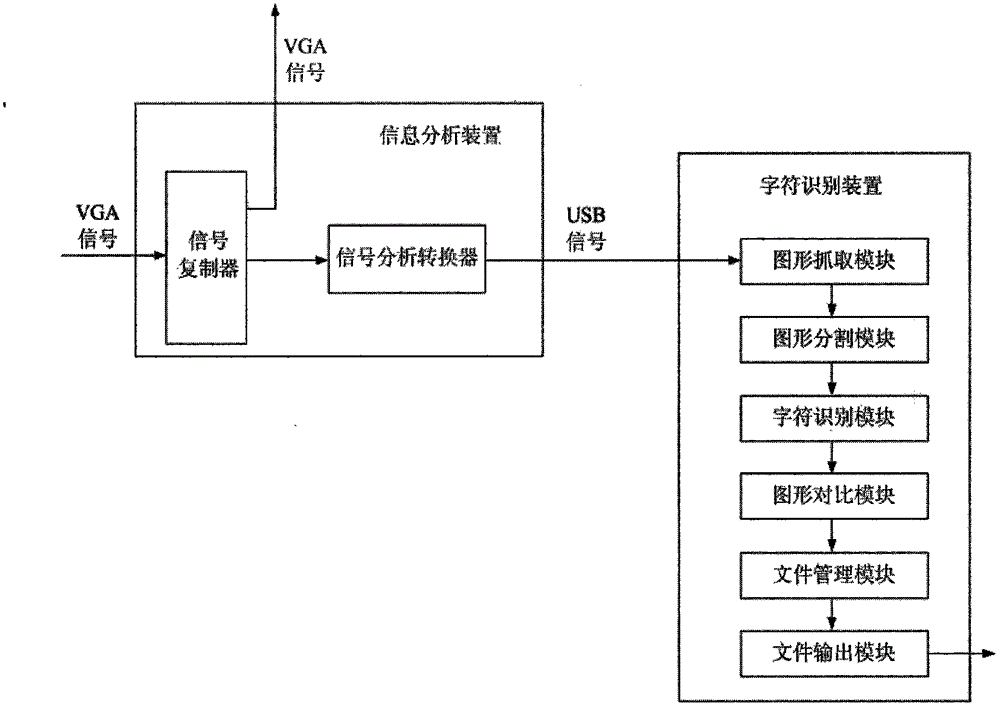

[0035] refer to figure 2 , which shows a functional block diagram of the parameter automatic input system proposed in this embodiment.

[0036] Based on the foregoing embodiments, here, a parameter automatic entry system is proposed, such as figure 2 As shown, the parameter automatic input system includes: the signal analysis device and the character recognition device of any one of the above-mentioned embodiments. Wherein, the signal analyzing device is used for acquiring VGA signal and converting it into USB signal. The character recognition device is used to analyze and identify the USB signal converted from the VGA signal, identify the USB signal and obtain equipment production parameters therefrom.

[0037] Among them, without affecting the use of its original equipment, obtain the VGA signal of the equipment, and analyze the VGA signal, and use the programming language such as activating the screenshot function to intercept the currently required USB signal through the...

Embodiment 3

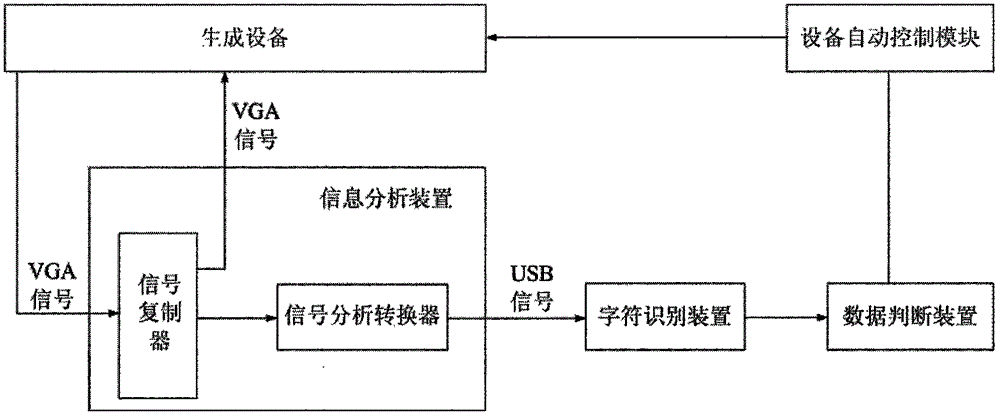

[0054] refer to image 3 , which shows the functional block diagram of the parameter automatic comparison system proposed in this embodiment. Here, in order to analyze the stability of the equipment through multiple sets of data, an embodiment of the present invention proposes an automatic parameter comparison system based on any of the foregoing embodiments, and the automatic parameter comparison system includes: automatic input of parameters in any of the foregoing embodiments A system, a data judging device and an equipment automatic control module. Among them, the parameter automatic input system is used to identify the input equipment production parameters.

[0055] The data judging device (for example, SPC (Statistical Process Control, Statistical Process Control) system) is used to record and analyze the equipment production parameters identified by the automatic parameter input system, and when the equipment production parameters meet the preset standard production pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com